Doug68

|

| posted on 14/4/09 at 12:52 AM |

|

|

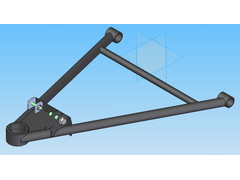

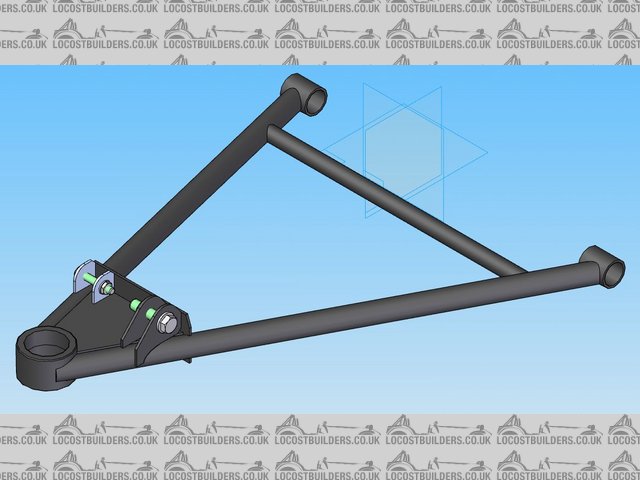

In the lower ‘A’ arms, given the way the hiem joints are being used, I do not understand why there is a need to come out at right angles to the

chassis with the first tube?

If you went straight from the hiem joint to the outer ball joint mount I would have thought there would not be the need for the X in the wishbone and

that a straight tube going across with a plate on top for the shock mount would be sufficient then?

Doug. 1TG

Sports Car Builders WA

|

|

|

|

|

Gakes

|

| posted on 14/4/09 at 11:03 AM |

|

|

very true, not sure why I never did it that way in the first place.

Oh yes, the reason I thought the x is necessary is because my front lower wishbones are quite long. Do you think that the straight pipe design is

stronger for the longer wishbones, its most certainly a mush lighter design.

And by the way, great CAD work!

|

|

|

Doug68

|

| posted on 14/4/09 at 12:29 PM |

|

|

On my design the 'A' arms are quite long also...

The lower fronts are 545mm long by 375 across the base.

The lower rears are 535mm long by 450mm wide

Obviously the tops are shorter but the width across the mountings is the same.

The picture is of a lower rear, the fronts are basically the same design but with a central shock mount.

I'm using 1" by 0.080" CDS tube for the arms mostly, I believe this to be sufficient, but that's yet to be proven on the road.

The most common failure I've seen in wishbones is bending, which I personally believe is due to the outer shock mount being too far inboard.

The other modes of failure would be the lower rear tube collapsing when the wheel runs into a hard obstruction (a big pot hole for example).

Similarly that might tear out the welding one the front lower tube as its in tension.

These are my guesses, again I'm lacking practical experience in breaking these parts personally.

Rescued attachment Capture.JPG

Doug. 1TG

Sports Car Builders WA

|

|

|

Gakes

|

| posted on 15/11/09 at 09:46 PM |

|

|

Some update pics:

Description

|

|

|

designer

|

| posted on 16/11/09 at 07:36 AM |

|

|

Nice build.

Have said this before, I still think there is too much front chassis. the distance from the peddals to the front bulkhead seems too much.

Shortening will move the CofG back, save weight and, probable, make the car 'nippier', easier around bends.

Still a good car.

|

|

|

Gakes

|

| posted on 16/11/09 at 09:11 PM |

|

|

Thanks...

I c now wot u r talking about, but if I show u from the top right-side angle u'll c that theres hardly any space behind the pedal box as it

narrows to the front.

Only other option is to have the pedal hung instead of floor mounted, just means more brackets!

Thanx for the input...I want to make the pedal box adjustable as well.

[Edited on 17/11/09 by Gakes]

Description

|

|

|

cheapracer

|

| posted on 29/11/09 at 05:38 AM |

|

|

quote:

Originally posted by Gakes

very true, not sure why I never did it that way in the first place.

Oh yes, the reason I thought the x is necessary is because my front lower wishbones are quite long. Do you think that the straight pipe design is

stronger for the longer wishbones, its most certainly a much lighter design.

My front arms are over 600mm in length and simple A shape with one central support.

Another quality SolidWorks 3D image ...

It's coming....

|

|

|