chassis cockpit design

MikeR - 19/12/03 at 11:45 PM

I'm playing around with little bits of wood trying different chassis designs. I'm trying to build something that would look like a modern F1

car using a spaceframe - well i've got to keep myself occupied on these cold nights! The problem i'm having is, errrm, not sure how to

describe this....

the bit of the frame that forms the edge where the steering wheel is mounted can move sideways too much when the chassis is twisted. This is due to no

diagnoals holding a top corner of the cross member to the opposite lower member. I could only put one in if i cut my legs off ......

Any suggestions how I can remove / reduce the distortion when the frame is twisted?

(Too much is defined as I can see it moving and am thinking "Ooooh thats a weak point!"

Cheers,

Mike

kestrel1596 - 20/12/03 at 01:59 AM

One option is to add a "perforated hoop" as used on the Lotus 19 or some other type of stiffening sheetmetal bulkhead to reinforce the

space.

Kevin B.

JoelP - 20/12/03 at 09:49 AM

maybe if you triangulate (an X would be better) behind the seat and infront of the pedal box, and make the air intakes triangular. this would all add

strength to the chassis.

MikeR - 20/12/03 at 10:47 AM

Yeah i was sort of expecting that response. The problem is...

a) construction in real life unless its okay to make two squares one inside the other with the steel between them

b) construction in the model, tried something similar and it wasn't that strong!!!! although that could have something to do with me using bbq

skewers, card and hotglue for that test

and ...

c) it would impose in the cockpit too much, these F1 cars area little tight!

Any other ideas? I'm currently looking at making the side pods structural and using some forward bracing that will be hidden under the skin

around the radiator.

kestrel1596 - 20/12/03 at 08:33 PM

I'm not sure I understand your "square in square" idea, but I think it is basically the same as the hoop.

Here's a file that shows the 19's chassis' use of hoops (two).

Kevin B.

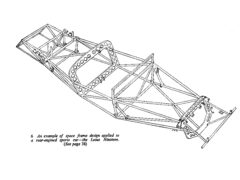

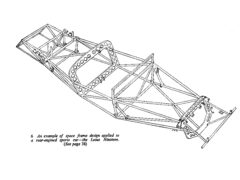

Rescued attachment Lotus19chassis.gif

JoelP - 20/12/03 at 10:08 PM

well, that certainly gets first prize in the biggest picture competition...

robinbastd - 20/12/03 at 10:18 PM

and most informative

MikeR - 21/12/03 at 01:46 AM

So its not just me who can't see it .... phew.

The square in a square thing - yeah basically my way of doing what the lotus 19 did with a oval as i can't bend tube.

kestrel1596 - 21/12/03 at 02:25 PM

Sorry about the size of the attachment: I've got to learn how to scale these things...

Kevin B.

Alan B - 21/12/03 at 02:50 PM

Being visible wouldn't hurt either..

Seriously though thanks...whatever it is..

MikeR - 21/12/03 at 09:10 PM

Kevin, Based on your comment I guess you can see your attachment - unfortunately no one else can.

TheGecko - 21/12/03 at 09:47 PM

Hmmm,

I can see the image but it is ENOURMOUS (4875 x 2784 pixels) and it's a GIF file. The combination may upset some browsers - I use Mozilla and it

works fine. Attached is a scaled (20%) version - see if that works.

Dominic

Scaled pic of Lotus 19 Chassis

kestrel1596 - 21/12/03 at 11:19 PM

That's it: thanks Dominic!

I'm using Firebird at home, so I could see the image I posted, although it took forever for the page to load.

Any suggestions on what size and format image will fit on a typical page here? (I haven't played around much with resolutions or graphical file

formats: I wanted to post a jpg but couldn't find a tool I already had to create one.)

Kevin B.

sgraber - 22/12/03 at 03:19 PM

It's be nice if that first enormous image that can't be seen would be removed. I have to scroll everbody's repsonses to read them. Ah

well.

If I were to try to duplicate the Lotus hoops in my little garage, I would make the inner and outer hoops out of two square tube steel frames, then

use an Ali sheet to cover the frames with the lightening holes cut in it  and bond it to the two steel structures with VHB tape and rivets. IMHO

that would be very strong and very light and very easy to fabricate.

and bond it to the two steel structures with VHB tape and rivets. IMHO

that would be very strong and very light and very easy to fabricate.

Graber

MikeR - 23/12/03 at 12:40 PM

Steve, thats the sort of comment I want to hear! I'd still be tempted to weld steel instead of bond and rivet ali - In my mind this is a high

fatigue / stress point and I'd just rather trust welded steel!

and bond it to the two steel structures with VHB tape and rivets. IMHO

that would be very strong and very light and very easy to fabricate.

and bond it to the two steel structures with VHB tape and rivets. IMHO

that would be very strong and very light and very easy to fabricate.