More pics at:

http://members.rogers.com/projectlmp/

After much wittling of metal tubes I have finally got something that looks like a chassis. Good job too because I've had all I can take of

cutting and welding tubes for now. Looking forward to doing some machining. Not to mention I can now clean that horrible grinding dust off

everything!

More pics at:

http://members.rogers.com/projectlmp/

Looking very good...

It's fun isn't it?..

Looks very, very nice...

IM building one very simalar to you... coincidence.

IMO, wouldnt it have been alot easier to use square tube? Ill certainly be using it...

Very very nice, cannot wait to see the body

Shug.

That does look good. I would very much like to do a mid engined car once the locost is finished, though am put off about the whole bodywork thing.

I've seen Alanb's progress, which makes me realise how slow a process making bodywork is. I recon I'd be able to design and build a

chassis, but would be stumped with the bodywork. The one option I did think of was to get some bodywork and design something round it, though I'm

sure this is the wrong way to do it!

Ned.

quote:

Originally posted by gsand

......IMO, wouldnt it have been alot easier to use square tube? Ill certainly be using it...

quote:

Originally posted by ned

That does look good. I would very much like to do a mid engined car once the locost is finished, though am put off about the whole bodywork thing. I've seen Alanb's progress, which makes me realise how slow a process making bodywork is. I recon I'd be able to design and build a chassis, but would be stumped with the bodywork. The one option I did think of was to get some bodywork and design something round it, though I'm sure this is the wrong way to do it!

Ned.

Paul,

Your frame is awesome and I just want to make my admiration for your design and fabrications skills a matter of public record.

You are the king. I'm not worthy!!!!

Graber

First class all the way, Paul. Design, execution, shop, tools, everything!!

Enviously yours  ,

,

Pete

Very,very nice........the car,the workshop,everything. In fact your workshop is nicer than my house. And bigger!

Keep it up

Ian

Thanks for all the complements. At the moment it just looks pretty, the real test will be in the driving!

Seriously, I think the two most important things when tackling a project as massive as a home build car are: Self belief that you can do it and

patience. This forum has certainly helped me on the first point and everyone's projects have offered inspiration to me in one way or another.

Answers to a couple of questions:

>IMO, wouldnt it have been alot easier to >use square tube? Ill certainly be using >it...

I would agree with Alan on this one, square is good for simple boxes but multi- tube complex joints are a nighmare. Round isn't too difficult

with the right tools and a bit of practise. However, I would say it is definately more time consuming. Probably at least twice or three times the

effort depending on the joint. Hoever, the joints are definately stronger and you end up with a lighter frame.

>In fact your workshop is nicer than my >house.

My workshop is probably nicer than the rest of the house! You've got to get your priorities right  (helps being single!)

(helps being single!)

Very nice looking. Mine started out looking like that, then as the months went by while I put all the "other stuff" on, it kept getting

more and more rusty

If you hate cutting, grinding, and welding, just wait until you start with all the numerous brackets

Paul, whats the wheelbase and track between centres? Just curious

Shug.

Where does the engine go in all that lot? I can see the seating area but the space looks tight in the back. I'll agree with the brackets thing, I

spent two days drilling and bending bits of metal to hang the axle and wishbones on. How do you fasten them to a round tube or do you make two pieces

with the tube profile and weld them on seperate? Sounds easier. Can't wait to see it on wheels.

yours, Pete.

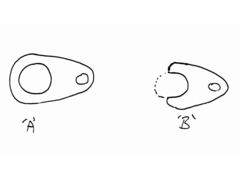

We used to make round tube brackets like this...

Type A were good if you could slip them over the tube first

Type B were easy to make in pairs

Notice how much weld you can get on them compared to square.

Good old holesaws to the rescue....

round tube bracket

[Edited on 18/11/03 by Alan B]

[Edited on 18/11/03 by Alan B]

exactly as id planned (makes sense instead of putting in square tube where your brackets go). course it could be down to the fact that great minds

think alike!

i have the luxury of a plasma cutter so wont be needing any quaint little hole saws  except for fishmouthing my tubes of course.

except for fishmouthing my tubes of course.

chassis looks good btw!

Russ.

Shug, the wheelbase is 98" and track approx 61"

Petef, I don't have a picture but if you go to the design section of my site you can

see a mock up of the engine located in the balsa model. It might look tight but in fact there is a lot more room than in a Radical SR3 or Westfield

XTR2.