Melkus PT 73 Spyder

liftarn - 6/3/07 at 08:58 PM

In researching mid-engined designs I found this interesting thing from East-Germany. It's the Melkus PT 73 Spyder (inspired by the Škoda Metalex

I'm told). Just new bodywork for the Melkus RS 1000.

Anyway, the design doesn't look that bad and it should be quite easy to make yourself from sheet metal.

Doug68 - 7/3/07 at 12:49 AM

Building a replica East German sports car now that's an esoteric endeavor!

liftarn - 7/3/07 at 11:49 AM

Porsche 917-30

Well, the design is about the same as similar cars (CanAm?) from the era such as Porsche 908/03, Porsche 917/30 or McLaren M8A, but with less compound

curves (i.e. simpler to make from sheet metal).

You should probably not have two huge fual tanks on either side (consider the effect of a side impact). Instead get some extra elbow room.

As for the choise of engine. The original Melkus PT 73 Spyder was powered by a 1100 cc, three cylinder two-stroke engine. I have a 2000 cc

turbocharged SAAB engine that I have no use for. That would make it possible to keep up with modern traffic.

[Edited on 8/3/07 by liftarn]

Doug68 - 7/3/07 at 12:57 PM

The general public would think that we are all a bit nutty here.

If the average person in the street were to think about it all (which they don't because they're mostly sheep) they'd expect the

owner-builder to want to copy a Ferrari or a Lambo.

So I congratulate you on finding a project that would truly confuse the unthinking public.

My recollection is the Saab engine sits on top rather than next to the gearbox. Won't that make it a bit tall to hide bodywork?

liftarn - 7/3/07 at 02:06 PM

quote:

Originally posted by Doug68

My recollection is the Saab engine sits on top rather than next to the gearbox. Won't that make it a bit tall to hide bodywork?

Yes, like the Audi engines it used an U drive, but it's not very tall since it's a bit slanted (altough not as much as the Triumph slant-4

it's derived from).

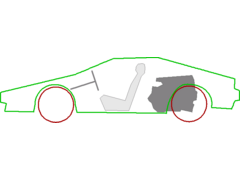

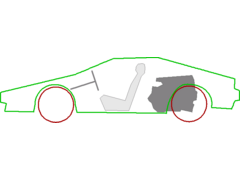

This shows the SAAB 900 engine in place in a Lotus Esprit outline.

Mid engine is perhaps better

As you can see it's not that tall. I have noticed that many CanAm cars are wedge shaped so I may just make it higher in the rear so it will be

able to cover the engine. You could ofcourse have the engine sticking up, but that's not very practical.

I aslo notice the Edge Devil ( http://www.edgesportscars.co.uk/ ) that uses Audi engine and gearbox.

[Edited on 7/3/07 by liftarn]

liftarn - 25/3/07 at 08:25 PM

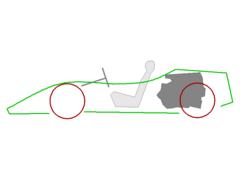

900 engine in McLaren M8A?

Somewhat inspired by the McLaren M8A Chevrolet Can-Am. The McLaren ofcourse had the top of the engine sticking out. I would have it enclosed for

practical reasons.

kb58 - 26/3/07 at 12:05 AM

I discovered the consequences of having the engine enclosed is lots of required attention for heat management. Something to keep in mind.

Dick Bear - 26/3/07 at 06:34 AM

Liftarn,

Your selected mid-engine project looks a lot like my adaptation of the McLaren M8B known as the McBearen.

http://metalmeet.com/forum/showthread.php?t=4020

I say, "go for it". As you do, share your progress with all of us......... lots of photos!

Dick Bear

liftarn - 26/3/07 at 07:11 AM

quote:

Originally posted by kb58

I discovered the consequences of having the engine enclosed is lots of required attention for heat management. Something to keep in mind.

Huh? The engine is enclosed as it is and I never had any probems with overheating. Is it something I'm missing?

Ok, the airflow over the engine will probably be a bit less then when it's in the front, but can it make a major difference?

I have considered placing the radiator in the rear, behind the engine since it's a bit tight fit in the front. That may be a problem, but with

some gills and an electric fan it should b enough.

And thanks for the tip on the McBearen. I'll read it carefully. I would probably make more of a spaceframe design (the McBearen looks much like a

ladder frame). But keep in mind that I'm not building an exact (or even aprox) replica, rather I'm taking inspiration from many different

sources to create something simmilar, but of my own design.

I plan on making the body of the car in alu sheets in simple curves so there will be a lot of visible rivets. I'm a bit worried about that. Will

it make the car look cheap or like a racer?

[Edited on 26/3/07 by liftarn]

liftarn - 3/4/07 at 04:29 PM

Beating a dead horse

Sorry to bring this up again, but what is the problem with enclosed engine bays?

DIY Si - 3/4/07 at 04:53 PM

It's generally the lack of air flow. The engine itself won't alter much, but everything attached to it can and will, given enough time.

Whilst it ma be"nicer", cleaner etc to panel it all in, the engine bay will get stupidly hot and cook electrics. You may also get random hot

spots on the engine, due to the lack of the cooling air flow. My mini engine bay used to get so hot the bonnet would steam quite happily in the

rain!

As for the rad, if possible, try to put in the front, lying near horizontal, as it gives extra space where you want it (at the back) and plenty of

extra coolant to help with any heating/cooling issues.

liftarn - 3/4/07 at 09:39 PM

Perhaps I'm missing something here but there should be air coming from both below and from the vents above and/or side.

Doug68 - 4/4/07 at 05:39 AM

The rear, underside & sides of a car are typically low pressure regions aerodynamically.

Therefore you either move what needs air to a natural high pressure region such as the nose of the vehicle or you stick something out into the airflow

to catch air which creates drag.

Look are most mid engined cars like Ferrari's and there are large vents either to the top or rear of the engine bay (probably both). The purpose

of these is to allow air to be sucked out into the low pressure region behind and above the rear of the car.

rpmagazine - 4/4/07 at 09:38 AM

I recently founf out the problem with enclosed engine bays. I drive a 1964 Rochdale Olympic (google it) and it has an enclosed engine bay apart from

the floor, which is open. Last run, the exhaust melted the engine mount and the engine bay sides became very warm indeed (inspite of 3 layers of

reflective insulation)...not at all good in a flammable car. You MUST get air in there

Ratman - 6/4/07 at 08:50 PM

quote:

Originally posted by liftarn

I plan on making the body of the car in alu sheets in simple curves so there will be a lot of visible rivets. I'm a bit worried about that. Will

it make the car look cheap or like a racer?

I would say that building this way will get you some comments about it looking unprofessional... but I would like to encourage you to stick with this

plan. I am impressed with the fine finish achieved by many builders, but they are often mostly seeking to match production car looks. When you build

yourself you don't have to meet any "look" standards except your own, and why make something that you can already buy in a shop? I

would suggest: use LOTS of rivets, large ones and preferably the aircraft type that you press or beat flat (not pop rivets) as these look better and

are stronger. Rivet on extruded Al sections under the skin in a geometric pattern. looks cool and makes the structure very strong. Have a look at a

wrecked light plane or helicopter for ideas. You will need to have a few double curvature bits. unavoidable. You can either develop these (lobster

back) or roll or beat and polish these pieces (not easy.. I tried and gave this up as too hard) or just make them from fibreglass and regard them as a

feature rather than a problem.. paint orange or mat black or something. With this can-am look, another option would be a wooden body made from thin

ply. Not as strong, or as safe, but fun to make and could look very cool. About engine heat.. I would suggest keep the rear end and underside

completely open, put heat sheilds on hot parts and keep plenty of space round the engine wherever you can. Air should flow very freely up from bottom

and out through rear. Cheers, Brian

[Edited on 7/4/07 by Ratman]

liftarn - 7/4/07 at 12:40 PM

I have actually considered thin plywood (perhaps skinned in alu like the Locust). I have also considered making the side panels sqrewed on so I could

remove them for easy access to the plumbing behind.

I was thinking of using the side pods for some storage space, but perhaps they could be use to lead air from behind the wheel arch back to the

engine...

Perhaps I'll have an open top for the engine and make some kind of detachable protection for it. I know hear can be a major problem on mid

engined cars. I once ended up behind a Ferrari Testarossa in a traffic jam during summer and you could really see heated air above the engine bay.

Ratman - 8/4/07 at 07:34 AM

your idea to make separate pannels that screw on is I reckon the easiest way to build a body. This may not make yeild the most beautiful body (as you

can see from the avatar) but it is a cheap, light weight and simple way to build. And, it is very easy to change afterwards if you don't like

some part of it. Examples might be.. most motorcycles.. smart car. Also, you don't need so much space in your workshop.

liftarn - 8/4/07 at 08:11 AM

In my opinion the die panels on the Roadrat is not the problem, but the stubby nose.

If you don't want to mess with fibreglass, don't have the skill (or equipment) to shape metal and can't afford to buy a kit (and they

don't fir my intended donor anyway) you have a problem...

Perhaps a cigarr shape like the Terrapin might work better...

A very interesting design based on the SAAB 900 is described at http://www.locostsweden.se/ipb/index.php?showtopic=3843

The front an rear are fibreglass, but at least you'd have the molds ready.

akumabito - 8/4/07 at 09:56 AM

quote:

Originally posted by liftarn

In my opinion the die panels on the Roadrat is not the problem, but the stubby nose.

Blasphemy! There is no problem with the Roadrat!

Doug68 - 8/4/07 at 12:42 PM

Rivets can look good if done well, look at any commercial airline for example do they look half finished or cheap?

Keeping with the Iron curtain theme the MIGS & Sukoi's had a more utilitarian finish than their western counterparts with a few rough edges

and sticky out rivets here and there and that didn't seem to slow them down any.

Also there's Landrovers to look at.

akumabito - 8/4/07 at 01:56 PM

quote:

Originally posted by Doug68

Also there's Landrovers to look at.

Me loves you long time.

...except maybe that Land Rovers (especially the beat-up old ones) do sortof look 'half finished and cheap'..

I'd say go for the riveted look. If too many people comment on the vehicle looking half-finished and cheap, let some of the panels develop a

healthy crust of rust, bang a couple of good dents in the panels, paint the rest of the car matte black or olive-drab, hang some jerrycans and some

camouflage nets on it and call it a post-apocalyptic Mad Max racecar..

Doug68 - 9/4/07 at 03:27 AM

Even Bugatti did it!

Rescued attachment Bugatti_T57_SC_Atlantic_1937_r3q.jpg

Peteff - 9/4/07 at 09:58 AM

My mate's brother has a lightweight LandRover which is now painted matt black and I will vouch for it looking cheap and unfinished  It's

fun though. If you want to build it, go ahead you don't need anyone's approval.

It's

fun though. If you want to build it, go ahead you don't need anyone's approval.

[Edited on 9/4/07 by Peteff]

liftarn - 9/4/07 at 01:15 PM

I managed to track down the two persons building two mid-engined, SAAB powered racers.

They have a project thread (you may need to register yourself to be able to view it) at

http://rejsa.nu/forum/viewtopic.php?t=32575&sid=a4e0324a259bc00e018a9c10b36f49e7 and it looks quite good.

Let me know if you can't see the picture.

[Edited on 10/4/07 by liftarn]

Doug68 - 9/4/07 at 01:59 PM

My Swedish is not that good but I think you need to be registered on the site to follow the link.

liftarn - 9/4/07 at 02:21 PM

Yes, that's something new.

Did the picture work? If so perhaps you could go to http://217.25.33.49/rejsa/rejsa/userimages/_garage/9711-new_2007-04-05-lcr23st.jpg and have alook

at the intended result.

Doug68 - 10/4/07 at 06:29 AM

That looks very nice. Do you know what package was used to create the model?

liftarn - 10/4/07 at 01:40 PM

quote:

Originally posted by Doug68

Do you know what package was used to create the model?

They didn't say. Just that it was a coworker that helped with it.

gottabedone - 17/4/07 at 07:28 PM

Hi,

It is quite easy to get a professional look to your work if you are willing to put in the time and care.

Whatever fastener you use (pop or solid) will look good if all of your lines are straight and parallel with your edges. Keep your pitch between rows

of rivets uniform. All aircraft panels are riveted at a pitch dependant on the loading of the panel. A good place to start is with a row of rivets

that are 1/8" diameter and about 1/2" from the edge of the panel (4x the rivet diameter). Make the pitch (distance between rivets) 4x

diameter of rivet. Then run a second row parallel, again at the same pitch but starting halfway between the rivets in first row. A bit like....

o o o o o o o

o o o o o o

Getting the rows straight and parallel will make any fastener look good. As for the smooth fastening of panels - get some dzus fasteners.

have fun

regards

Steve