I bought a new engine - FJR1300

sgraber - 4/4/05 at 03:58 PM

I've always been semi-serious about running la Bala as a BEC, but it always seemed that the 1 liter class bikes would be just a bit too low

torque to move the car briskly off the line and in traffic. But when I saw that MK had used an FJR1300 in an Indy and saw the numbers for the engine I

knew that it was a potential powerplant.

It was almost serendipity that I saw the FJR1300 motor on ebay just after reading about the FJR powered Indy in the BEC forum. The seller lived less

than 15 minutes from my house, the engine had less than 2,000 miles on it and no one had bid on it. With a starting bid of $400 and a buy-it-now price

of $800, I thought that maybe this was a sign from on-high that the engine should be mine!

I drove over to the sellers house yesterday, took a look at the engine and several boxes full of wiring, lights, switches. It was the entire running

motor and all components minus the exhaust and the clocks, which had both been destroyed in the accident. Everything else was in perfect condition

except for a few minor scratches on the magneto casing. The engine is based on R1 technology. Here are the

specifications

I offered the seller $500 and he took it. So I just bought myself a 2003 FJR1300 1.3 liter Yamaha bike engine with shaft drive output. Final drive is

3.66:1 with a 24" tall wheel.

My neighbor Justin has a Honda (Acura) LS transmission sitting in his garage, and as you know the Honda engines are reverse rotation.... The output

from the FJR shaft drive is reverse rotation... Seems logical that they should fit together? That would give me reverse in the box. I would strip all

unused gears out of the Honda transmission to save weight.

My other options are 1) mate the output shaft to a flipped differential like MK did on their Indy 2) use a Porsche 915 transaxle 3) machine the side

of the transmission case to remove the shaft drive bevel gear and return the rotation to standard.

Comments, suggestions?

Edited to show engine age of 2003...

[Edited on 4/4/05 by sgraber]

locoboy - 4/4/05 at 04:05 PM

You sneaky devil,

Dont you have enough work to do without adding a bike engine into the equation!

sgraber - 4/4/05 at 04:08 PM

Yes I do have a lot on my plate, but the bike engine route has been my not-so-secret passion all these years. I started out with a Venture V-4 engine

over 2 years ago, but always thought that the reverse rotation was a show stopper. I think I can drop 150Lbs off the back of the car with this swap.

I can pick up this engine by myself so I think it it under 200Lbs. A turbo option is not off the table either.

I won't start on the engine swap until I am past the Bodywork Phase later this year. I am thinking that it will be a summer/fall project.

[Edited on 4/4/05 by sgraber]

smart51 - 4/4/05 at 05:17 PM

not enough torque to pull away in traffic? the latest R1s and similar bikes can make a locost accelerate from rest to 60 MPH is 3 or 4 seconds. just

how much acceleration from rest do you need?

kipper - 4/4/05 at 06:13 PM

I had a little giggle to myself at your mention of the magneto case just how old is this engine.

Looks like a nice motor though, should make you car gallop.

sgraber - 4/4/05 at 06:20 PM

quote:

Originally posted by kipper

I had a little giggle to myself at your mention of the magneto case just how old is this engine.

Looks like a nice motor though, should make you car gallop.

The reference to magneto shows how old I am! The motor is 2003 with less than 2000 miles. It probably has a generator, not a magneto right?

kreb - 4/4/05 at 07:26 PM

I'm confused. Is it a 1993 or 2003? Don't mean to be negative, especially considering your considerable accomplishments to date, but I have

to ask, do you want to keep engineering solutions, or do you wnat to get the car on the road? If it were me, I'd stay with the automotive

solution till the prototype was on the road, then try BEC for #2.

sgraber - 4/4/05 at 08:17 PM

quote:

Originally posted by kreb

I'm confused. Is it a 1993 or 2003? Don't mean to be negative, especially considering your considerable accomplishments to date, but I have

to ask, do you want to keep engineering solutions, or do you wnat to get the car on the road? If it were me, I'd stay with the automotive

solution till the prototype was on the road, then try BEC for #2.

The engine is 2003. That was a typo in my original post.

Technically the car was mechanically finished almost 6 months ago with the 4AGE drivetrain. It's just the bodywork/Interior that needs to be

completed now.

I don't intend on the BEC taking time away from my finishing the bodywork. I will finish the car in its current mechanical configuration. (I have

to! Since the car is underneath the plug!) The car will remain as a CEC until it passes the police inspection and becomes road legal.

It's always been my goal to use bike power. I am simply closer to my goal now that I bought the powerplant. It will go into storage until the

bodywork is finished.

Ratman - 4/4/05 at 10:34 PM

Hi Steve

My suggestion is to make a trike, with the engine between the front two wheels and driving the single rear wheel (ex bike) via an extended drive

shaft. This gives a simple light stable safe layout, but there will be wheelspin. Definately a fun drive, and lots of bodywork options. One thought is

to make it a two seater, with the passanger slightly to the rear of the driver, so that the body can be made more narrow. With the left side drive

shaft it will work better with Right Hand Drive than LHD. Just a thought.. I am very envious of that motor. Brian

ProjectLMP - 5/4/05 at 12:50 AM

Welcome to the sequential world!

Alez - 5/4/05 at 10:28 AM

> It's always been my goal to use bike power. I am simply closer to my goal now that I bought the powerplant.

I'm very impressed that you put a car engine in there just as a kind of intermediate phase of your project.

I'm very impressed that you put a car engine in there just as a kind of intermediate phase of your project.

sgraber - 5/4/05 at 01:54 PM

quote:

Originally posted by Alez

> It's always been my goal to use bike power. I am simply closer to my goal now that I bought the powerplant.

I'm very impressed that you put a car engine in there just as a kind of intermediate phase of your project.

I'm very impressed that you put a car engine in there just as a kind of intermediate phase of your project.

My original donor car, the 1985 MR2, was given to me by a friend who bought it at an insurance auction for $50 because it would have been crushed had

it not sold. He gave it to me because he had no room for it and his wife was upset that there was another "non-runner" in front of their

house!

I used the MR2 engine because #1 it IS a nice engine, #2 it was free #3 it was convenient. But the draw to small displacement, hi-revving engines has

always been great.

Graber

tadltd - 5/4/05 at 11:14 PM

To solve the reverse rotation issue (and overcome the lack of reverse), why not install a reverse gear unit - something akin to the Quaife or

Nova unit - and run it in

'reverse' all the time...

I don't have personal experience of how robust these units are, but I know the Nova unit is used as standard on the Legends racers, and on

Caterhams with bike power.

Can't remember which unit was used to set the world speed record in reverse, but I'm sure the car was a Caterham.

Correction - it WAS the Nova unit. The car achieved a speed of 103mph! Now there's a record for the taking....

[Edited on 5/4/05 by tadltd]

sgraber - 8/4/05 at 07:41 PM

I have been debating the pros and cons of all the different ideas for getting the power out to the half-shafts and believe me, I have a lot of

ideas.

The problem I have is finding the proper balance of cost/performance/weight.

I think the option that makes the most sense right now is to use a Honda transaxle in transverse configuration. Remove some gears from inside it to

reduce weight. Tie the output shaft of the FJR directly to the input shaft on the Transaxle. Packaging may be an issue. Did someone mention that the

Pell Genesis did this? Any photos or weblinks?

Thoughts? Suggestions?

Rorty - 9/4/05 at 03:57 AM

Steve, well done on taking the step. Try these people for one of their reverse options: Jaxports

sgraber - 9/4/05 at 04:24 AM

Thanks Rorty, for that link and vote of confidence. That is one expensive little box!

I found some cutaway photos of the FJR shaft area and started to think about the possibility of converting to side output by removing the 90degree

bevel gear, sealing the hole out the back, creating a new hole out the side of the case (where a chain drive would normally go) and inserting a

propshaft adapter onto the splined shaft where the bevel gear would have been. I think that there's probably some horsepower to be found by doing

that?

I know that there are a number of companies creating chain drive conversions for the V-Max so technically it should be doable. But what steps would be

required to get there? Would the cost be greater than the reward?

Take a look at these photos.

And I believe that the bevel gear goes at the end of the upper shaft in this next photo. I would want to mate a propshaft adapter to mate onto this

and run it out the side of the gearcase past a seal.

Rorty - 9/4/05 at 05:15 AM

I like your thinking, but I think there may be too many drawbacks.

For instance, there doesn't appear to be any removeable side casing directly oposite the end of the gear shaft, because the crank cases are

horizontally split, so you would be hanging a bearing in the side casing. Not a simple task.

You may be better off mounting the engine longitudinally and putting a sprocket on where the UJ is and then treat it as a chain drive application.

Spyderman - 9/4/05 at 02:24 PM

Sounds like you are trying to re-invent the wheel!

Put the engine aside for now and finish off your bodywork. I'm sure you will have thought of something by then.

I often find that forgetting the problem and going on to other things helps clear the mind and a solution often pops up!

Apart from which we are all eagerly awaiting the next episode in body making!

Terry

sgraber - 9/4/05 at 02:44 PM

quote:

Originally posted by Spyderman

Sounds like you are trying to re-invent the wheel!

Put the engine aside for now and finish off your bodywork. I'm sure you will have thought of something by then.

I often find that forgetting the problem and going on to other things helps clear the mind and a solution often pops up!

Apart from which we are all eagerly awaiting the next episode in body making!

Terry

I understand you Terry. Many solutions have come easiily after leaving something for a few days. The bodywork phase is hard, time consuming and

tedious. If I don't break it up with something fun and exciting I will lose my mind... Besides. I am only thinking about the new engine when I

can't physically be in the Garage, so it's not actually taking time away from the bodywork...

I will be on bodywork patrol all weekend and will post an update by Monday.

Graber

www.grabercars.com

turbo time - 9/4/05 at 04:07 PM

Oooh man, this'll be interesting, but I'm betting that once the bodywork/car are complete, you won't want to touch the car, you'll

just want to drive it for a while. Although I don't know your plans for it, if you are going to drive it on the street a lot, wouldn't the

ole toyota 1.6 work much better for reliability and drivability?

Aloupol - 9/4/05 at 08:04 PM

Hi there..

Steve, one more idea for the transaxle: you could use a chain driven diff with the engine in longi position?

Pros: simple, light, cheap.

Cons: exhaust configuration, lateral weight bias and/or inequal shaft lenghts.

Aloupol - 9/4/05 at 08:42 PM

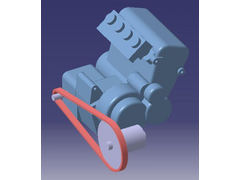

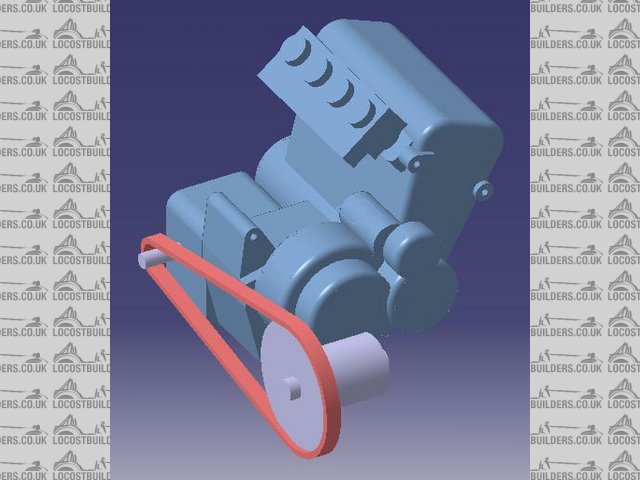

Something like this..

Stays the reverse gear problem...

Rescued attachment FJR1300.JPG

yahshuatwo - 11/4/05 at 02:24 AM

Cool deal for that engine. A steal !!

Would like to see the FJR in the la Bala

sgraber - 11/4/05 at 06:28 PM

FYI - I am discussing the Differential issue over in the BEC forum. I thought that might be a better place for it? <shrug>

http://www.locostbuilders.co.uk/viewthread.php?tid=24838&page=1#pid201364

Graber

MrFluffy - 25/4/05 at 06:48 PM

Steve, if that motor is the overboard version of the r1, (which definately is chain drive) you could be in luck, sorry dont know the newer ones, but

its a development of the old fj1200/fzr1000 motors that I run one of... When a bike manufacturer makes two models based round the same design(ish),

its always worth taking a look at the chain variant to see if the shaft drive is just a bolt on conversion that they added later and thus lets you

revert back by changing the parts to the other variant. This is the case on some of the kawasaki's that I know about anyway..

Also, the gear selector drum etc you can see in that shot usually live just under a cover and are supported in single shear by the inner crank case

wall on chain drive models, so Id think the odds are good that you can just replace that bevel with a sprocket and use the outer casing from the other

model. It probally has the outrigger bearing to resist the extra side forces created by the bevel gear over a sprocket which should just have axial

ones. You need to find someone into tuning fjr's

sgraber - 27/4/05 at 02:59 PM

@mrfluffy - That is an idea worth looking into for sure. Thanks. I have shop manuals for both R1 and FJR1300 (Thanks Rorty) and I can probably compare

the differences there before tearing into the motor.

[Edited on 4/27/05 by sgraber]