you can do anything you want inthis game its just the more different it is the longer it takes

Just wondering if it was possible to setup a bec in a mid-engine configuration with an automoitve drive shaft and irs? Just like the front engine bec

cars but with a mid-engine and a shortend drive shaft?

Thanks.

yes why not, if ihave understood you correctly

you can do anything you want inthis game its just the more different it is the longer it takes

Sounds like you're describing the Fisher Fury Menace (Mid ENgined ACE) - it's been featured in a few of the kit mags recently - it uses a very short propshaft. I can't rememeber if it has IRS or not though.

Hi Dean

That's the configuration I'm hoping to use myself. The Fisher Fury Menace uses that layout as do the Coram LMP and the new middy from MK.

I believe we can do away with the driveshaft completely with a carefully designed flexible coupling -- I've been looking at industrial couplings

(as used between large electric motors and hydraulic pumps) but I'm thinking about simply purchasing a ready made piece from one of the

manufacturers).

I'm working on mastering SolidWorks at the moment so I can convert my napkin scratchings into something useful.

How far along in the process are you?

Cheers, Ted

quote:

Originally posted by andkilde

I believe we can do away with the driveshaft completely with a carefully designed flexible coupling -- I've been looking at industrial couplings (as used between large electric motors and hydraulic pumps) but I'm thinking about simply purchasing a ready made piece from one of the manufacturers).

quote:

Originally posted by Dean

Just wondering if it was possible to setup a bec in a mid-engine configuration with an automoitve drive shaft and irs? Just like the front engine bec cars but with a mid-engine and a shortend drive shaft?

Thanks.

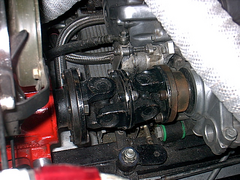

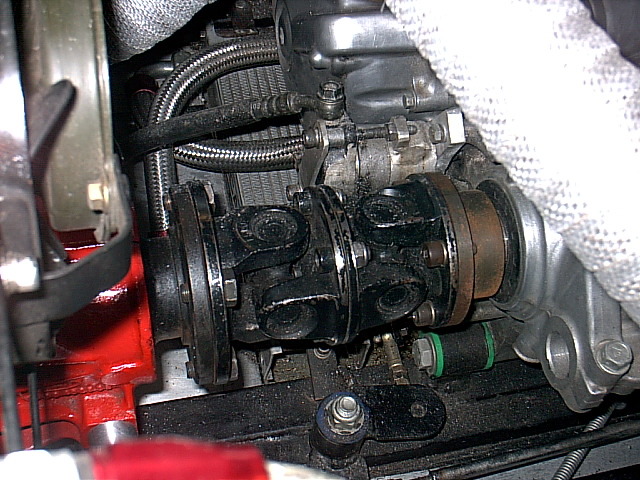

spunky, is that two sierra UJs bolted together? looks good, does it work well?

clutch adapter 2

[Edited on 2/8/04 by JoelP]

Yuh, exactly like that. So, in your opinion then, there is no need for a means to separate vibrations between the engine and 3rd member, assuming

they're both well mounted to the frame?

I assume a live axle would put the cat amongst the tree rats, then, as the whole axle needs the ability to move up and down.

FWIW, I'm still in the exciting thinking about it stage, although I have bought some cheapish parts, so I'm still open in most respects.

Anything I should bear in mind that you can think of from your experience?

-Steve

Hi Sven, Joel, you're right, it is simply two UJ's bolted together.

Certainly does what its meant to do. The engine is mounted rigidly, so there is no movement, which would be a problem with such a short prop. the

advantage is the power transfer is very 'direct', the disadvantage is the engine vibes are passed through the whole chassis. That is only

really noticeable in the mirrors at certain revs.

I took a lot of time ensuring the allignment of engine and diff were perfect (this goes against the theory for 'normal' prop shaft

arrangements) but I wanted it balanced. there is no chance of oscillation on prop that length.

Sven, the only thing that springs to mind is mount the engine first and give the diff. mounts a bit of slack or slots. That way the coupling can be

torqued up fully without the risk of stressing any mounts.

Mine are slotted, giving around 3/8" to play with, as I plan on fitting an electric reverse and want to sandwich the flywheel between the UJ and

diff flange.

This idea can only work with IRS or De-Dion not live axle.

John

Thanks John. I thought about mounting the motor using stiff rubber engine mounts and the diff using rose/heim joints so it could be adjusted fore and

aft as necessary.

Thanks for your suggestions.

-Steve

I read somewhere about a joint using 2 sprockets with a piece of duplex chain round them. I can't remember where or when but it sounds like an idea worth studying.

quote:

Originally posted by Peteff

I read somewhere about a joint using 2 sprockets with a piece of duplex chain round them. I can't remember where or when but it sounds like an idea worth studying.

Dennis Palatov of DPcars.net is attaching his Hayabusa engine using rubber donuts from a BMW driveshaft... Does this help? (Since I have no practical

experience in these matters)

edit - oops link to http://www.dpcars.net it's the little silver beasty he's building...

[Edited on 8/3/04 by sgraber]

Sounds a lot like what I am trying to build all though my work as staled some what. However I would be interested in swapping Ideas. The last thing I did was have some plates laser cut so that I could mount bike front disks directly on to a sera diff.

quote:

Originally posted by ceebmoj

Sounds a lot like what I am trying to build all though my work as staled some what. However I would be interested in swapping Ideas. The last thing I did was have some plates laser cut so that I could mount bike front disks directly on to a sera diff.

quote:

Originally posted by Peteff

I read somewhere about a joint using 2 sprockets with a piece of duplex chain round them. I can't remember where or when but it sounds like an idea worth studying.

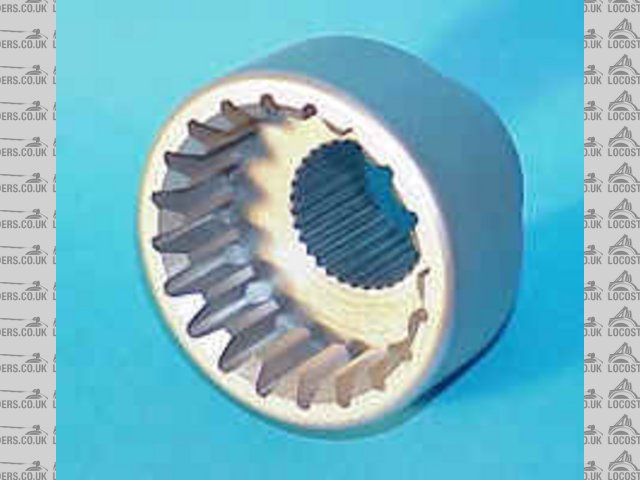

Some of the industrial transmission flanges are perfect for this. They come with a variety of splines/flanges/fixings and and the male and female halfs are cushioned with a separate polyurethane "star". Some are designed to handle up to 500 hp and high torque figures.

quote:

Originally posted by Hugh Jarce

Some of the industrial transmission flanges are perfect for this. They come with a variety of splines/flanges/fixings and and the male and female halfs are cushioned with a separate polyurethane "star". Some are designed to handle up to 500 hp and high torque figures.

ermm, if you look at the photo I posted above you will notice that the rubber piece being used by DPCars is a BMW bog stock part for the driveshaft

(320i?) and it is exactly what you are talking about but designed for a car....

They still must be around 5.5" diameter. very similar to the old Hillman Imp 'doughnuts' (English spelling) would have been too tight

for my installation without cutting chassis members.

Worth bearing in nind though.

John

quote:

Chris Allison of Zcars does the bits for this type of drivetrain

that rubber donut looks exactly like the one on the girlfriends 316 compact. i noticed the other day when putting the spare wheel back on the car

under the boot.

Ned.

quote:

Originally posted by spunky

They still must be around 5.5" diameter.

If your worried about the harshness of drive train, its worth noting that most bike engines have some sort of cush drive in the clutch hub (which will be retained), along with the rear wheel. If it all gets snatchy after a year or so of abuse, worth checking that the cush drive hasnt broke up...

task your local "Wyco" sales rep (or equivalent bearing supplier) with a headache

tell him all the torque figures, rpm, angular

offset, shaft sizes, rolling diameters...etc... and he will come up with the goods, works for me at work anyway, when I can't be arsed to fathom

it all out...

tell him all the torque figures, rpm, angular

offset, shaft sizes, rolling diameters...etc... and he will come up with the goods, works for me at work anyway, when I can't be arsed to fathom

it all out...

Not sure if this is relevant, but IIRC in the early bec days, some people tried to use sierra propshaft rubber doughnuts (very similar to the beemer

one in the photo) for some reason becs tore them to pieces. Seems weird as some sierras, V6 ect put out much more torque and bhp than most becs. Maybe

its the rpm they dont like?

i]Originally posted by sgraber

Dennis Palatov of DPcars.net is attaching his Hayabusa engine using rubber donuts from a BMW driveshaft... Does this help? (Since I have no practical

experience in these matters)

edit - oops link to http://www.dpcars.net it's the little silver beasty he's building...

[Edited on 8/3/04 by sgraber]

Wadders,

I would have guessed it would be both the rpm and the speed at which the revs rise on a bec which is quite different to a sierra I would imagine.

Ned.

Spunky - can you be ABSOLUTELY certain that you have removed ALL vibration from you set-up?

When designing the LMP we specifically avoided this set-up because there is no way that you can assume everything is rigid and free from movement. If

you put a small camera in there, and pointed it at the 'prop', you'd be amazed at how much movement you'd see.

That's why we adopted a 'normal' sliding prop' and in 2 years of testing, it has never let us down.

There are pictures in my photo archive - admittedly poor - but you can just about see our set-up.

Steve, A very far point, and TBH There aint no way I can be sure, The engine and diff are rigid and aligned as good as possible, the only way I could

have done a better job would be with dynamic alignment setting. There is little vibration when driving, in fact it is better than I expected.

I asumed, maybe incorrectly, that a double UJ prop, even one so short, would allow a tiny amount of misalignment.

Lets not forget that the LMP is in a different league to my little Sp1der...

John