Paul TigerB6

|

| posted on 12/7/07 at 03:14 PM |

|

|

Sump Ground Clearance

Hi all,

Just need some help here with regards to ground clearance for the sump.

I am fitting a 2005 R1 engine into a Tiger B6 (a first). The highest point of the engine is the Throttle Position sensor which basically sits on the

side of the throttle body. In order to get the engine low enough so that it will fit under the bonnet (only 21.5" from the bottom of the chassis

rail to the bonnet) i have around 60mm / 2 1/4" of ground clearance to the bottom of the sump.

Question is - is this enough??

[Edited on 12/7/07 by Paul TigerB6]

|

|

|

|

|

Minicooper

|

| posted on 12/7/07 at 03:25 PM |

|

|

I think 4 inches is the least for a road going car, at 2 and a quarter you would need to run a sump guard which will further reduce ground clearance,

the sump is only thin cast alloy if it hits anything it will shatter it

Cheers

David

|

|

|

zxrlocost

|

| posted on 12/7/07 at 03:35 PM |

|

|

david is quite right

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

Paul TigerB6

|

| posted on 12/7/07 at 03:46 PM |

|

|

bugger - i wish Dave was wrong. So, whats the options to gain the ground clearance?? Is there a way of moving the throttle position sensor at all??

Shallow sump?? Graft a bulge to the bonnet prior to it being painted??

Argh!! I thought the new R1's were small!! How did Tiger get a ZX12R under there - even with a modified sump!!!

|

|

|

ChrisGamlin

|

| posted on 12/7/07 at 05:09 PM |

|

|

You havent said how high you're running the car, maybe a more relevent measurement would be how far the sump hangs below the base of the chassis

rails?

|

|

|

Paul TigerB6

|

| posted on 13/7/07 at 10:49 AM |

|

|

quote:

Originally posted by ChrisGamlin

You havent said how high you're running the car, maybe a more relevent measurement would be how far the sump hangs below the base of the chassis

rails?

As it stands with the engine positioned to give me the tightest of clearance on the bonnet given the measurements supplied by another Tiger owner

there is 2 1/2 inches of sump below the chassis.

Ride height will be 4 3/4 inches - maybe a touch higher.

Really am stumped on this at present so any suggestions appreciated.

|

|

|

Paul TigerB6

|

| posted on 13/7/07 at 11:23 AM |

|

|

R1 Sump clearance issue

Having looked at the manual it is actually the Sub-throttle servo motor assembly that is sitting very high on the 05 R1 engine. Has this not caused an

issue with anyone else??

Edit.

Having looked through the history there is mention (by Chris Mason) of turning the throttle bodies around which will drop the sub-throttle servo motor

assembly out of the way. Looks to me like the perfect answer to my problem but has anyone done this or seen any links to websites detailing it.

http://www.locostbuilders.co.uk/viewthread.php?tid=65585

Cheers

Paul

PS dont you just love this forum!!!

[Edited on 13/7/07 by Paul TigerB6]

[Edited on 13/7/07 by Paul TigerB6]

[Edited on 13/7/07 by Paul TigerB6]

[Edited on 13/7/07 by Paul TigerB6]

|

|

|

ChrisGamlin

|

| posted on 13/7/07 at 12:18 PM |

|

|

If you can't do the throttle body flip as youve mentioned, I suspect the only solution is going to be a hole / scoop on the bonnet to give you

enough room as 2.5" below the chassis rail is too much IMHO.

cheers

Chris

|

|

|

Paul TigerB6

|

posted on 13/7/07 at 12:44 PM posted on 13/7/07 at 12:44 PM |

|

|

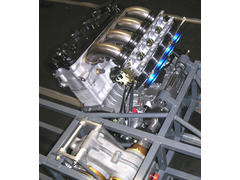

Well having had a look at it i will gain a little bit but not much due to the fuel rail as can be seen in the picture. This raises the question of

fitting a sausage air filter too!!! Selling the engine and fitting something different is seeming an attractive option at present!!

Rescued attachment throttle bodies front.jpg

|

|

|

Coose

|

| posted on 13/7/07 at 01:03 PM |

|

|

Can you not remove the secondary butterflies? They're only there to stop cack-handed born-again bikers from highsiding....

Spin 'er off Well...

|

|

|

kb58

|

| posted on 13/7/07 at 01:04 PM |

|

|

Selling the engine only changes the problem but doesn't solve it. If you're willing to sell the engine, find out the dimensions of the

replacement so that the very same problem doesn't happen.

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

Paul TigerB6

|

| posted on 13/7/07 at 01:27 PM |

|

|

quote:

Originally posted by Coose

Can you not remove the secondary butterflies? They're only there to stop cack-handed born-again bikers from highsiding....

I dunno mate - can I remove the secondary butterflies along with the servo motor??? If so then this would be a better option i guess. Bit of a newbie

to bike engines myself so i'm relying on you guys here!! As you can see from the pic - the servo sticks up quite high - probably 40 - 50mm.

So if i do this is it simply a case of removing the servo motor and then the grub screws locating the individual butterflies - but leaving the spindle

in place??

I'm not running standard clocks so are there any wiring issues i would need to look at?

|

|

|

Minicooper

|

| posted on 13/7/07 at 01:34 PM |

|

|

Like you say you will need an airfilter anyway and that will a bit higher again, ideally you don't want the sump below the chassis rails, I have

seen a completly flat sump using a dry sump setup but that will no doubt be an expensive complicated solution.

Buying another modern engine won't sort your problem as all of the modern engines have downdraught carbs/fuel injection pointing straight up in

the air and the R1 has one of the most compact flat sumps available.

The easiest thing is to move it up and sort an opening or bulge to cover it, plenty of the bike engined cars have done this and they look great

Cheers

David

|

|

|

Paul TigerB6

|

| posted on 13/7/07 at 01:39 PM |

|

|

quote:

Originally posted by kb58

Selling the engine only changes the problem but doesn't solve it. If you're willing to sell the engine, find out the dimensions of the

replacement so that the very same problem doesn't happen.

I'm not really gonna sell the engine!  I'm sure with the help of all you guys on this site we will come up with a way of getting this

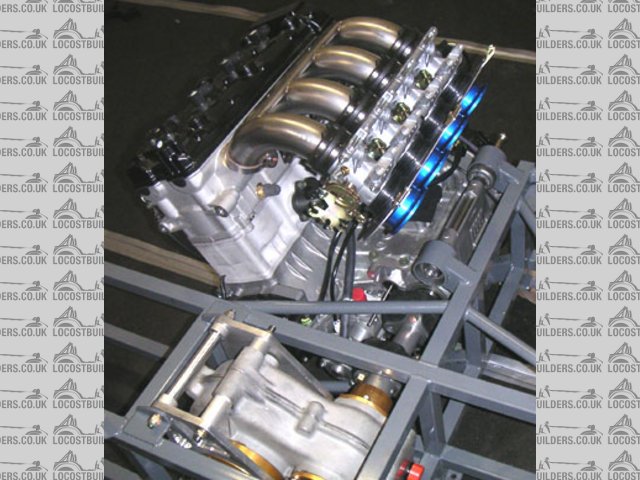

engine fitted - looks like we may just have a solution that will gain me enough sump clearance. As you can see, even Tiger themselves seem to have an

issue getting a GSXR1000 under the bonnet with the TB's sticking out!! I'm sure with the help of all you guys on this site we will come up with a way of getting this

engine fitted - looks like we may just have a solution that will gain me enough sump clearance. As you can see, even Tiger themselves seem to have an

issue getting a GSXR1000 under the bonnet with the TB's sticking out!!

Rescued attachment tiger-b6-mk2.jpg

|

|

|

Paul TigerB6

|

| posted on 13/7/07 at 02:57 PM |

|

|

More searching on the 05 R1 secondary butterflies resulted in the following quote from Cossey. Do you have any more info on this and am i going to

need to go to Megasquirt then??

Thinking about it a PC3 is somewhere around the £250 mark isnt it?? I have a US loom / ECU that i could sell on that does away with the need for coded

key so all in all Megasquirt might be cost effective for me anyway????

"the newer r1 has secondary butterflys but the engine can go dangerously lean if you remove them because the stock ecu doesnt seem, even with a

pc3, to be able to properly sort out fueling. with the upgrades coming out soon the megasquirt will soon be able to run the engine fine (atm its

missing sequential injection and coil on plug ignition drivers) but that looks like a good idea because then you can go to a closed loop setup at

lower throttle and open loop/mapped for higher throttle and it will make it alot easier to pass emissions without neutering the engine"

[Edited on 13/7/07 by Paul TigerB6]

|

|

|

adithorp

|

| posted on 13/7/07 at 03:25 PM |

|

|

I've got an '06 R1 and it looks like I'll have similar problems (when I get some bodywork). I wanted to have the sump flush with

the chassis but I'm considering dropping it a little if that will get me under the bonnet but if it's a lot too high I'll use a

bulge.

I don't think turning the throttle bodies will work as you won't loose much height, apart from it being seqential injection so would be

injecting the wrong cylinders (unless you re-do the wiring). I've just made up an air box and remote filter.

Adrian

|

|

|

adithorp

|

| posted on 13/7/07 at 03:33 PM |

|

|

I did wonder about putting some curved tubes between the head and throttles so that they were horizontal. It would mean moving the thormostat housing.

Don't know how this would affect the fueling though as it would extend the inlet tract. and still don't think it'd gain a lot height

wise.

Adrian

|

|

|

Paul TigerB6

|

| posted on 13/7/07 at 04:02 PM |

|

|

The more i look into it the more i feel that maybe the MegaSquirt may be the answer to this. Removing the secondary butterflies saves about 2.5 inches

off the height. Cost of MS system can be offset on the saving of the PC3 - but obviously will need extra rolling road time.

Thoughts gents???

|

|

|

Minicooper

|

| posted on 13/7/07 at 04:12 PM |

|

|

How about this, standard injection although this is a hayabusa using a curved manifold

More details are on this site,

http://www.dpcars.net/

cutting your injection into lots of bits doesn't sound like an easy option to me, then the megasquirt plus you'll need a different trigger

wheel, which is much bigger and has to be mounted outside the engine, it all gets messy quickly

Cheers

David

[Edited on 13/7/07 by Minicooper]

[Edited on 13/7/07 by Minicooper]

Rescued attachment dp1 curved manifold.jpg

|

|

|

ChrisGamlin

|

| posted on 13/7/07 at 06:24 PM |

|

|

Thats a horrible solution IMHO, the injectors are designed to fire atomised fuel straight down the throats of the inlet tract, with that lot in

between its going to upset the fuel / air mix quite a bit. You might actually end up with a bit more mid-range torque at a certain rpm but I bet

you'd lose out at the top end.

|

|

|

Minicooper

|

| posted on 13/7/07 at 09:16 PM |

|

|

It works well Chris, injectors can fire fuel in any direction, that's why it was invented

Cheers

David

[Edited on 13/7/07 by Minicooper]

|

|

|

ChrisGamlin

|

| posted on 14/7/07 at 09:09 AM |

|

|

Injectors can fire in any direction yep, but assuming they've just used the standard throttle bodies bolted to these extensions, that direction

is fixed to suit their original application of firing it straight down the throats of the inlet tract so is unlikely to be ideal in this situation.

Its not just that though, in any engine a long inlet tract (even if straight) has an effect on how fast the fuel/air mix enters the cylinders, hence

why some (mainly car) engines now have variable inlet tract lengths. Long and narrow for low rpm to maximise the speed of the mix into the engine

helping lower speed torque, short and wide for high rpm to maximise power. From what I understand (and its a bit hazy I must admit), long and wide

might not actually be very good at low speeds either because the air speeds through the manifold at low rpm may not be fast enough to keep the

fuel/air mixed together and you can end up with the fuel droplet essentially going too slow to make it al the way to the engine so they end up on the

manifold walls if you're not careful.

|

|

|

Minicooper

|

| posted on 14/7/07 at 10:07 AM |

|

|

He didn't make the manifold himself it was bought of a company

http://www.super7cars.com/index.html

They use it on all of there hayabusa cars, so you would have to assume it works. You wouldn't need to go the size and curvature of there

manifold say something like half and have the the throttle bodies horizontal or even a slight angle down back to the head.

I myself wouldn't be to keen on that manifold, mainly because the throttle bodies are upside down, and any unused fuel perhaps may leak back

into the air filter

Cheers

David

|

|

|

ChrisGamlin

|

| posted on 14/7/07 at 12:04 PM |

|

|

Yeh Im sure it "works", I guess what Im saying is that its not an optimimal or best practice way of setting up throttle bodies on a high

performance engine, and it will reduce the power a bit.

|

|

|

Paul TigerB6

|

| posted on 14/7/07 at 12:43 PM |

|

|

I think i am just going to have to bite the bullet and position the engine so that i gain the sump clearance and investigate further removing the

secondary butterflies as that looks the ideal solution - IF we can sort the fueling!! Otherwise i guess its going to have to be a bonnet bulge over

the servo motor.

Has anyone managed to fit a sausage filter directly to the TB's?? Looks like with the servo motor one side and the fuel rail the other that

these would get in the way unless the back plate is spaced out.

Cheers anyway guys.

Paul

|

|

|