CraigJ

|

| posted on 31/5/07 at 10:57 PM |

|

|

My Chain diff build

Thought id put up a few pics of the chain diff im making. Cut out a few parts at work today.

heres the diff from a 1.8 sierra

one side welded

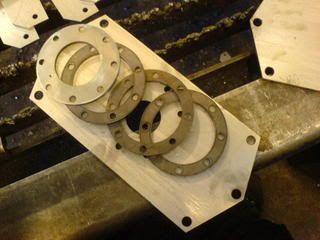

side mounting plates cut from 5mm 316 s/s

I made the bearing housing from 3 rings of 6mm mild steel with a 2mm end plate.

The bearings im using

All together

Ive made this diff from s/s and mild to start with but i plan to make it from ali once ive tested it to make sure it will be strong enough. Once its

all ali it will drop a kilo or two.

|

|

|

|

|

nitram38

|

| posted on 31/5/07 at 11:30 PM |

|

|

Very nice work!

I bought mine from another locoster on here. He got it from Zcars.

It is an lsd from a XR 4 X 4.

The sprocket is only 42 teeth so Chris Mason worked out what I needed for 195/50/15 tyres and I got a 52 tooth sprocket from west garage engineering.

Top bloke Douglas and a good quality job. He has the sierra bolt pattern.

The bearings look like something you can buy ready made with the carriers:

diff1

52 tooth sprocket

[Edited on 31/5/2007 by nitram38]

|

|

|

CraigJ

|

| posted on 1/6/07 at 09:54 AM |

|

|

I looked at a few different bearing types but decided to go for the sealed one's as there lighter. The parts ive made will hopefully be recut

from ali if i can test it to see if it will be strong enough. My sprocket is being drawn up on the computer at work as we speak and i'll be

cutting it out later today. Mine will be a 42 tooth.

Its cost £50 for the diff and £33 for the bearing all the other parts i have cut havent cost a penny because ive used up a few off-cuts at work. If

made from ali it will cost around £110 all in. not bad to say most places ive seen charge around £3-400 lol.

|

|

|

CraigJ

|

| posted on 1/6/07 at 09:58 AM |

|

|

Forgot to ask what Type of metal is the new sprocket made from?

|

|

|

nitram38

|

| posted on 1/6/07 at 09:58 AM |

|

|

You can have my 42 tooth for a few beer tokens !

Made from Aluminium.

I just need a narrow 17mm socket to undo the countersunk nuts to get the sprocket off!

[Edited on 1/6/2007 by nitram38]

|

|

|

CraigJ

|

| posted on 1/6/07 at 10:07 AM |

|

|

Thanks for the offer but im a laser profiler so i can get the perks of cutting my own for free lol.

|

|

|

cloudy

|

| posted on 1/6/07 at 11:50 AM |

|

|

Excellent work, i'd like to convert mine from pillow blocks to a similar two panel config like yours for weight reduction

Have you found bearings that directly fit the seats on the sierra diff? I had to make up some ally spacer rings and buy oversized bearings to get a

good fit on my last attempt - if you have would love to know the bearing part no. and where I could get hold of two!

James

|

|

|

nitram38

|

| posted on 1/6/07 at 12:19 PM |

|

|

Cloudy, do a search for Orbic bearings.

They will get you a bearing that directly fit to the sierra shafts plus bearing carriers. It doesn't look like there are any spacers on mine,

but then again, I haven't taken it apart.

[Edited on 1/6/2007 by nitram38]

|

|

|

CraigJ

|

| posted on 1/6/07 at 09:12 PM |

|

|

The diff was 41.30mm in dia and the bore of the beraings are 39.70mm so i had to take a little of the diff to make them fit better.

|

|

|

zxrlocost

|

| posted on 1/6/07 at 09:29 PM |

|

|

neat work

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

kb58

|

| posted on 2/6/07 at 01:38 AM |

|

|

Doesn't the welding heat damage the diff? Warping it or ruining the internal bushings/bearings?

Also, I've always wondered how a sealed diff works. What I mean is, it seems to me that as it gets hot in use, the air inside's going to

heat up quite a bit, forcing oil past any seals. No?

[Edited on 6/2/07 by kb58]

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

nitram38

|

| posted on 2/6/07 at 03:12 AM |

|

|

quote:

Originally posted by kb58

Doesn't the welding heat damage the diff? Warping it or ruining the internal bushings/bearings?

Also, I've always wondered how a sealed diff works. What I mean is, it seems to me that as it gets hot in use, the air inside's going to

heat up quite a bit, forcing oil past any seals. No?

[Edited on 6/2/07 by kb58]

The casting is too thick to warp and there is a grease nipple on mine. It is packed as full as possible with grease.

|

|

|