Genesis

|

| posted on 1/1/06 at 01:06 AM |

|

|

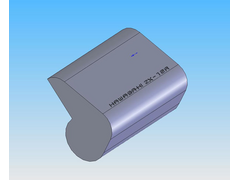

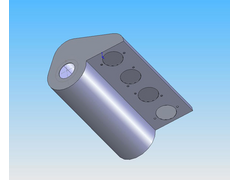

Kawasaki ZX-12R Airbox

Following extensive liason with airflow specialist's in the Netherlands I have finally designed an airbox of correct capacity for the ZX-12R.

This box is designed to fit onto the trumpets using the original Kawasaki rubbers and weighs less than 1Kg.

This design is proven and takes filtered ducted air from the front of the car into the throttle bodies.

Any thoughts would be appreciated

Rescued attachment zx12rairbox.jpg

Going fishin'

|

|

|

|

|

k33ts

|

| posted on 1/1/06 at 02:05 AM |

|

|

where exactly is the air coming from.

you really want it from outside of the engine bay.

eg: cool air =better combustion

|

|

|

Genesis

|

| posted on 1/1/06 at 02:56 AM |

|

|

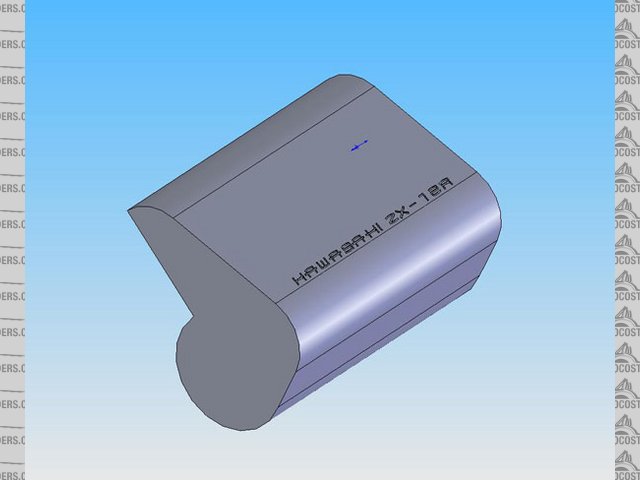

It's not visible in that drawing but is in the below drawing. The air is fed to the chamber from a nose mounted K&N Cone Filter which is

ducted to the chamber using 2" hose.

Inside the chamber is the inlet temperature probe for the ECU.

HTH

Rescued attachment zx12r-2.jpg

Going fishin'

|

|

|

jacko

|

| posted on 1/1/06 at 09:57 AM |

|

|

HI you say the box is fed by a 50mm pipe is that ok as the TB must be at least 40mm each making that 160 mm of air or am i wrong ? im in the middle of

donig the same on zx9r carbs i would like your thoughts please  Graham Graham

[Edited on 1/1/06 by jacko]

|

|

|

Genesis

|

| posted on 1/1/06 at 10:37 AM |

|

|

I am considering 4" ducting for this reason until I get confirmation - possibly not 2" as I suspect; as you; that 2" will restrict

flow.

[Edited on 1/1/06 by Genesis]

Going fishin'

|

|

|

ChrisGamlin

|

| posted on 1/1/06 at 11:46 AM |

|

|

Hi Genesis

Do you have any more info on what these airflow specialists told you, any equations etc that we could use for other engines?

cheers

Chris

|

|

|

Hellfire

|

| posted on 1/1/06 at 11:49 AM |

|

|

Chris (Mason), Demon Thieves stuff is done by Reverie. Have you had a look on their website for something suitable?

Link

[Edited on 1-1-06 by Hellfire]

|

|

|

the moa 2

|

| posted on 1/1/06 at 12:06 PM |

|

|

ReVerie stuff looks good but flipping expensive !!!

|

|

|

Hellfire

|

| posted on 1/1/06 at 12:22 PM |

|

|

Yeah, they don't look to difficult to copy, err I mean make

Looking at it again, that Mondello intake scoop does look quite complicated but I'm sure Triton would be up for the challenge.....

Phil

[Edited on 1-1-06 by Hellfire]

|

|

|

carlgeldard

|

| posted on 1/1/06 at 03:09 PM |

|

|

Hi Genesis

What file type is that Cad file. I would like to help produce a working prototype. And with my access cad software, tig welders and lazer cutting etc.

I think I could help. Is there any chance you could email it over so I can have a look.

Carl

|

|

|

Hellfire

|

| posted on 1/1/06 at 04:44 PM |

|

|

Do you have a vested interest in a ZX12R airbox then Carl

|

|

|

Bob C

|

| posted on 1/1/06 at 05:24 PM |

|

|

Just a note re: diameter of air pipe to the airbox: the fact is, each cylinder sucks in air in turn so from a 'restriction' viewpoint a

pipe not much bigger than 40mm would do. If you look at the choke size on a single carb with distributing manifold & compare to choke sizes on

DCOEs (carb for each cylinder) they're the same.

cheers

Bob

|

|

|

G.Man

|

| posted on 1/1/06 at 05:29 PM |

|

|

quote:

Originally posted by Bob C

Just a note re: diameter of air pipe to the airbox: the fact is, each cylinder sucks in air in turn so from a 'restriction' viewpoint a

pipe not much bigger than 40mm would do. If you look at the choke size on a single carb with distributing manifold & compare to choke sizes on

DCOEs (carb for each cylinder) they're the same.

cheers

Bob

Correct, if you look at the inlets on most airboxes they aren't as large an area as more than 2 chokes at most...

Opinions are like backsides..

Everyone has one, nobody wants to hear it and only other peoples stink!

|

|

|

Genesis

|

| posted on 2/1/06 at 12:10 PM |

|

|

Been offline a while so couldn't answer any questions... the volume of the airbox is paramount to get a good power figure. As the ZX12

doesn't have a speakable airbox as it uses the frame, the size replicates the system volume whilst being able to fit under a bulged bonnet.

Going fishin'

|

|

|

Genesis

|

| posted on 2/1/06 at 12:14 PM |

|

|

quote:

Originally posted by carlgeldard

Hi Genesis

What file type is that Cad file. I would like to help produce a working prototype. And with my access cad software, tig welders and lazer cutting etc.

I think I could help. Is there any chance you could email it over so I can have a look.

Carl

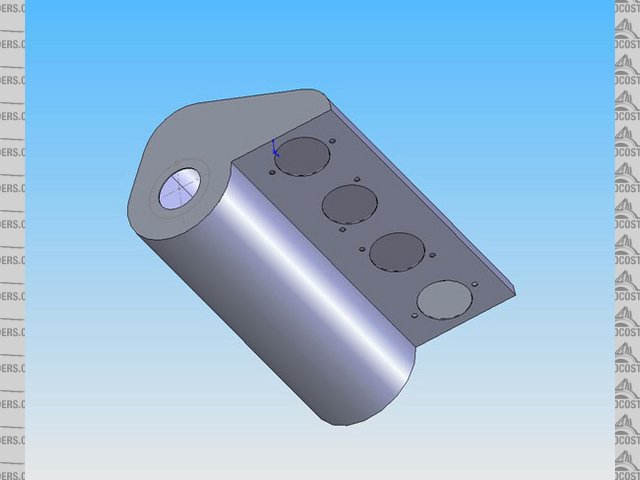

Hi Carl - many thanks for the offer and your resources re: equipment is very welcome. I'm sure you have a vested interested... TIG/MIG welding

1.2mm aluminium isn't a problem then. As it is a chamber - one end of the airbox will be left removable to work internally. This could be sealed

and rivetted once the rubber trumpets/air temperature sensor are installed.

BTW it is a Solidworks file - though can output into dxf/dwg - I think

[Edited on 2/1/06 by Genesis]

Going fishin'

|

|

|

G.Man

|

| posted on 2/1/06 at 01:02 PM |

|

|

quote:

Originally posted by G.Man

quote:

Originally posted by Bob C

Just a note re: diameter of air pipe to the airbox: the fact is, each cylinder sucks in air in turn so from a 'restriction' viewpoint a

pipe not much bigger than 40mm would do. If you look at the choke size on a single carb with distributing manifold & compare to choke sizes on

DCOEs (carb for each cylinder) they're the same.

cheers

Bob

Correct, if you look at the inlets on most airboxes they aren't as large an area as more than 2 chokes at most...

Yup thats why I said area, not diameter...

Even the inlet tubes for a Kawasaki zx6r ramair system are only equivalent to one choke each (total of 2)...

I like the look of this airbox, quite fancy one for my MNR...

Are you gonna get some made up in GRP once you have an ally pattern?

Opinions are like backsides..

Everyone has one, nobody wants to hear it and only other peoples stink!

|

|

|

carlgeldard

|

| posted on 2/1/06 at 02:23 PM |

|

|

I will have a vested interested on Saturday. You could try to exporting the file as an IGES file But I can work with DXF,DWG,ITP,IAF. I also know of

users with Soildworks so I should have no problems opening your files.

Carl

|

|

|

Genesis

|

| posted on 6/1/06 at 01:22 AM |

|

|

quote:

Originally posted by carlgeldard

I will have a vested interested on Saturday. You could try to exporting the file as an IGES file But I can work with DXF,DWG,ITP,IAF. I also know of

users with Soildworks so I should have no problems opening your files.

Carl

I can output to IGES (or *.igs) easily enough... will respond when manufactured prototype and tested on dyno. Sorry, I won't be manufacturing

from GRP... maybe I can get some made up from my mate up the road in CF? Incedentally the input port has been modified to a diameter of 145mm - must

be beneficial in some way?

[Edited on 6/1/06 by Genesis]

Going fishin'

|

|

|

carlgeldard

|

| posted on 6/1/06 at 07:52 AM |

|

|

Can you not just goto File,Save-as and then in the drop down menu below where you put the file name select iges file. Or just email the soildworks

file to Hellfire or myself and we will convert it. I think Phil (Hellfire) has access to somebody with solidworks.

Carl

|

|

|

Smartripper

|

| posted on 6/1/06 at 08:23 PM |

|

|

Hello,

There should be a larger airfilter in front because of size and normal is there the RAM airsystem.

I've got a 11 cm airfiler.

Cool thing about it is that you can weld the compleet airbox and assembel the trumpets thru the airfilter hole.

Smartripper

|

|

|

Genesis

|

| posted on 6/1/06 at 09:23 PM |

|

|

quote:

Originally posted by Smartripper

Hello,

There should be a larger airfilter in front because of size and normal is there the RAM airsystem.

I've got a 11 cm airfiler.

Cool thing about it is that you can weld the compleet airbox and assembel the trumpets thru the airfilter hole.

Smartripper

Exactly - already thought about this... is there a problem with welding 1.2mm plate?

RAM air has no effect on this engine until approx 150mph.

Carlgeldard - that is what I did... it does output (via post) to igs but it's not editable within SW, therefore it's not merely a save

as.

Hellfire - you have u2u.

[Edited on 6/1/06 by Genesis]

Going fishin'

|

|

|

Smartripper

|

| posted on 6/1/06 at 09:28 PM |

|

|

No trouble with welding 1.2 mm alu, just make sure it's stays flat because it wil warp if not done right.

Therefore let it make for me instead of trying 3 times and then let it make for me.

It's not so easy as it looks like.

Daniel

|

|

|