robertwa

|

| posted on 4/11/05 at 07:50 PM |

|

|

one piece prop?

Can anyone see a problem with using a one piece prop for my shaftdrive bike (FJR1300)?

I have a toyota 1 -piece prop from a Cressida. It is 51" long. The propshaft is the perfect length for my engine so I won't need to shorten

anything. The bike engine is mounted longtitudinally in the car (book frame)

Are there any reasons why it is bad to use a one piece prop?

The toyota used this length shaft - it wouldn't be spinning any faster than it would in its original application (assuming the car won't go

much faster then the original). I'm using a higher ratio rear end so that should slow it even more.

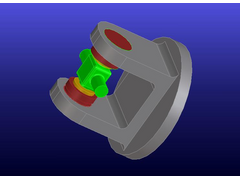

The bearing on the output shaft of the engine seems pretty sturdy (see cutaway below - taken at some bike show)

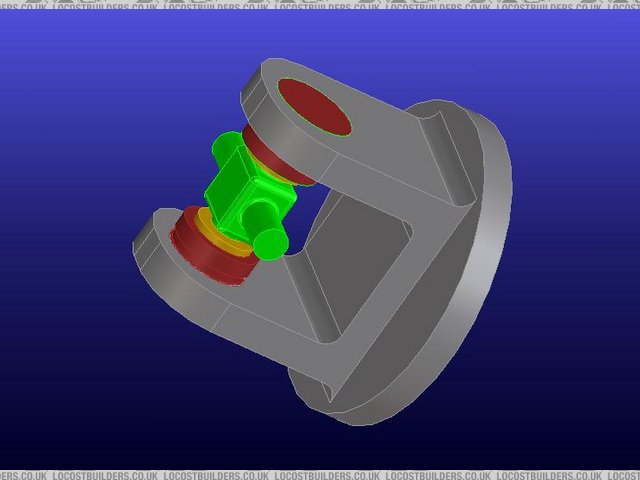

I have modified the toyota U-J yoke to accept the smaller bike UJ by machining two bearing caps (in red in the picture).

Description

fjr1300 install

|

|

|

|

|

JoelP

|

| posted on 4/11/05 at 08:08 PM |

|

|

the reason long props are bad is that vibration/wobble get exponentially worse with length. Since you are modifying the original prop, and its

spinning at a similar speed, i would guess its ok. The weakest link (no offense  ) will be your part. I was going to mention it the other day, but

didnt, because i assumed that to make it, you must be quite talented anyway. Just make sure its strong enough! If the diff is fixed, i would consider

putting some banding around both ends of the prop to catch it in case it fails - the closer you can get it, the less force it will have to contain ) will be your part. I was going to mention it the other day, but

didnt, because i assumed that to make it, you must be quite talented anyway. Just make sure its strong enough! If the diff is fixed, i would consider

putting some banding around both ends of the prop to catch it in case it fails - the closer you can get it, the less force it will have to contain

|

|

|

ChrisGamlin

|

| posted on 4/11/05 at 08:51 PM |

|

|

When you say a higher ratio rear diff do you mean numerically higher, or higher geared (numerically lower)?

Also what size tyres does the Toyota have as standard, if its has large rolling radius tyres that could make a big difference to the overall gearing

of the car, and hence the speed its prop spins at.

Chris

|

|

|

Danozeman

|

| posted on 4/11/05 at 09:05 PM |

|

|

Are using a fied diff? or live axle?

If its live axle u wil probably need a sliding joint somewhere to take up the movement in the axle.

If its fixed it should be a problem. Jsut make sure its protected at either end should it go bang.

Dan

Built the purple peril!! Let the modifications begin!!

http://www.eastangliankitcars.co.uk

|

|

|

robertwa

|

| posted on 4/11/05 at 09:17 PM |

|

|

I'm using a 3.46 diff from a Celica whereas the prop is from a Cressida which was a 4.2/4.3. I figure that slows the prop down for the same road

speed.

I forgot to mention that its a live rear axle if that makes any difference. The sliding part is on the UJ - engine interface.

The wheels I will be using are very similar in size to the Toyota ones

Roughly how much movement in and out (I guess I can measure it) is there on the splined end of a driveshaft for maximum suspension travel? The bike

U-J doesn't have as long a spline as a car one.

JoelP,

I like the idea of banding and think I will incorporate something for piece of mind.

I have the rear axle flipped upside down because of the bike output direction being oposite to norm. This leaves the shaft VERY close to the left side

of the tunnel, or my hip (LHD car).

[Edited on 4/11/05 by robertwa]

|

|

|

tks

|

| posted on 4/11/05 at 09:20 PM |

|

|

nahh

You cant do this...

its imposible...

i'm sad to say but an fixed prop isn't the way to go.

You need an center bearing wich is held by a rubber sow it absorbs vibrations..

Also you need an sliding part to be able

to compensate

- unbalance (there is always unbalance!!)

- temperature problems.. (crimping and expanding of you axle..) you haven't mounted you bike engine on rubbers do you?

- vibrations

What if you don't.

Well because of the nature that its impossible to get everything hooked up like we would like.. we need things to compensate this and an sliding part

in the axle does just that!

I used on my car just the standard sierra axle it has every part i mentiod: sliding part, rubber mounted centre bearing

and another plus, it has an rubber coupling for angle compensation...

When driving the axle want to crimp and grow..and that doesn't like every material,

also de loads on your bearing would't be equal...

at high revs is when the problem starts to grow..

see it this way: how do you now know that if you hook it up you aren't pulling the diff towards the engine or the engine towards the diff? if

you use an sliding part you are sure you cant! and when you engine heats up the output axle will grow

but there no compensation for that in your transmission...

advice:

buy an sierra shaft and donor the sliding joint/part.... and weld it in...

Tks

see it like the force of ice, its not the movement thats killing the filled botle in the cold, its just the 0,005 mm that the ice expands and that

will brake the glass!

and maybe in your situ the bearing last an bit longer...

but the movement will grow and then it gets very fast worser..

more movement ==> more vibrations ==> more movement ==> more vibrations ==> more bearings wear ==> more movement ==> more

vibrations..

[Edited on 4/11/05 by tks]

The above comments are always meant to be from the above persons perspective.

|

|

|

robertwa

|

| posted on 4/11/05 at 09:58 PM |

|

|

tks,

I thin you are mis-interpreting my post. There is a sliding piece - on the U-joint end that slips onto the bike output shaft.

I'm not using a regular BEC sprocket adapter - the bike already came with a sliding UJ as it is a shaft drive bike. What I am wondering about is

whether a one piece shaft is too long or will damage the engine output shaft bearing.

Rob

|

|

|

madman280

|

| posted on 5/11/05 at 01:56 AM |

|

|

On an automtive transmission the splined output shaft has a bearing on the inside and the yoke tube slides within a bushing that is part of the trans

case. The shaft is inside the yoke thats supported by the bushing. Then a seal on the end of the trans to keep dirt out and fluid in.

Kinda like this:

ZZ --------------------]

ZZ,,,,,,,,,,,,,,,++++++++++++++++

XXXXXXXXXXXXXXXX

ZZ''''''''''''''''''''++++++++

++++++++

ZZ --------------------]

where:

"+" is the drive shaft sliding yoke

"X" is the trans splined output shaft

" ' " and "," are the output sahft splines

"--" is the bushing in the trans case

"Z" is the output bearing

"]" is the output seal in the trans

If that makes any sense to ya.

Most bike transmissions have opposed tapered roller bearings or double row cartridge bearings. The shaft is cantalevered on the bearings and the end

of the output shaft is unsuported. There is a bearing to the far left outside of view in the picture you posted. So the shaft is well supported. No

need for the bushing.

ZZ,,,,,,,,,,,,,,,ZZ],,,--------

XXXXXXXXXXXXXXXXX

ZZ''''''''''''''''''''ZZ],,,--

------

The idea of the small adapter caps on the u-joint is a good one in my opinion. Simple small and easy to make.

The only issue you may have is the yoke travel on the output shaft splines. You'll want to make sure the yoke is well engaged in the splines

through the full range of rear end travel. You seem to have the reverse rotation diff worked out pretty well too.

Definatly an A+ for creativity and imagination.

[Edited on 5/11/05 by madman280]

[Edited on 5/11/05 by madman280]

|

|

|

madman280

|

| posted on 5/11/05 at 03:27 PM |

|

|

quote:

Originally posted by JoelP

the reason long props are bad is that vibration/wobble get exponentially worse with length. Since you are modifying the original prop, and its

spinning at a similar speed, i would guess its ok. The weakest link (no offense  ) will be your part. ) will be your part.

How many cars have been made with one piece driveshafts longer than anything in our cars? I really don't think its an issue. As to the

fabricated adapter failing, its possible, just like any other part, but probable? I don't know the actual dimensions or material specification,

but in the illustration it appears to be quite thick walled. As long as its properly retained with snaprings it shouldn't break as its enclosed

within the d/s yoke and the u-j within it.

|

|

|

JoelP

|

| posted on 5/11/05 at 05:22 PM |

|

|

well, each to his own. My mate made his own prop for an MK, it failed and he has the scar on his leg to prove it (he actually had the same pair of

torn jeans on too when he showed me it!). Props do fail. Obviously this one failed cos he didnt make it strong enough or balanced enough, but thats

not the point. It just proves that the prop is a stressed component, and weakness could easily take it over the edge. Seeing as a two piece prop isnt

much more expensive than a one piece prop, it makes sense to use one.

If you want professional input and a guarantee, go to a prop shop and ask if they will make you a one piece one, stating the max revs and

torque/power. If they do, all good, you can probably trust them. But length and rpm are factors that they are qualified/experienced enough to take

into account, as home builders we arent really.

To me its similar to the difference between the full 16th edition wiring regs and the onsite guide.

|

|

|

madman280

|

| posted on 5/11/05 at 10:53 PM |

|

|

quote:

Originally posted by JoelP

well, each to his own. My mate made his own prop for an MK,, it failed ........but thats not the point. It just proves that the prop is a stressed

component, and weakness could easily take it over the edge. ....

I agree some things are best left to profesionals. Is your mate a qualified welder, mechanic or machinist? I am the first two and my brother is the

third. I do agree that another opinion would be wise. Like I said, it doesn't seem to be a problem in any other car manufatured over the last 50

years.

[Edited on 5/11/05 by madman280]

|

|

|