loony

|

| posted on 23/2/12 at 09:41 PM |

|

|

DIY prop / sprocket adapter

Is there anybody who made DIY sprocket / propshaft adapter...

Or rather you just buy readymade ?

I'm looking for 2003 ZX9R adapter, but in Poland they are "not available". So my first thought - let's made one, but... now

I'm little lost.

|

|

|

|

|

twybrow

|

| posted on 23/2/12 at 11:05 PM |

|

|

HI Loony

I think most people buy them, as you would need access to a lathe (and mill for the splines?) and a heat treatment facility, as all the ones I have

seen have been hardened....

I'm sure the Locostbuilders population can figure a way of getting one to Poland on the cheap...!?

|

|

|

matt_gsxr

|

| posted on 23/2/12 at 11:27 PM |

|

|

I assume you have tried these guys?

http://www.sprocket-adaptors.co.uk/

|

|

|

loony

|

| posted on 24/2/12 at 07:30 AM |

|

|

Yes - I know them.

I send some inquiries to Polish machine shops if they can make me one, but... I'm still waiting for response

If I can't find one who make me adaptor or it parts - I will buy one from "sprocket-adaptors", MK or MNR... but in Poland should be

much cheaper  (it's not a rule - some things are more expensive here than in UK) (it's not a rule - some things are more expensive here than in UK)

There are "some" polish employees in UK, so it shouldn't be problem to bring adaptor to Poland.

Is there any reason I couldn't weld flange to bike sprocket ? Anyone tried this ?

People weld diffs, so why not flange to sprocket

My friend told me that he can laser cut/CNC some kind of adaptor, but can I weld it to sprocket...

[Edited on 24/2/12 by loony]

|

|

|

mark chandler

|

| posted on 24/2/12 at 08:19 AM |

|

|

I made mine

Took the bike sprocket and cut the middle out on a lathe (very hard metal) and put on a taper, male end.

Grabbed a scrap diff and removed the pinion prop flange, cut the end off and machined a taper so it dropped on the splined lump nicely, female end.

Welded it up, job done.

|

|

|

loony

|

| posted on 24/2/12 at 09:08 AM |

|

|

That's very good news

Any chance for pictures ?  But I think I know how you did it But I think I know how you did it

I'll be changing sprocket in my bike - so the old one will go to welding tests

[Edited on 24/2/12 by loony]

|

|

|

mark chandler

|

| posted on 24/2/12 at 09:18 AM |

|

|

Sorry, no pics I had a look

The centre of the sprocket is untouched, the teeth are very hard so I chopped off with an angle grinder before lathing down.

A taper just makes it centre nicely.

Regards Mark

|

|

|

loony

|

| posted on 24/2/12 at 11:05 AM |

|

|

Thanks Mark, everything is clear now.

I found someone else who made sprocket adapter himself.

tks's sprocket adaptor:

Rescued attachment Foto 006 small.JPG

He's from Spain - so I suspect he had same problem as I

"Doors open" - let's get to work

|

|

|

loggyboy

|

| posted on 24/2/12 at 11:08 AM |

|

|

quote:

Originally posted by loony

There are "some" polish employees in UK,

lol  lol lol

|

|

|

mark chandler

|

| posted on 25/2/12 at 01:38 PM |

|

|

I would not make one that long, it will waggle about !

It needs to be just long enough to clear the nut on the prop when you do it up, mine is a maximum of 1/2" further forward from where the

sprocket teeth lived.

You could just cut the flange off an old diff and weld on to the teeth of the original sprocket, I used a taper as it made lining up easy, it will

spin at up to 6000rpm when flat out so make sure it is accurate

Regards Mark

|

|

|

loony

|

| posted on 25/2/12 at 02:28 PM |

|

|

I know it's too long. But tks's engine was V2 so it was complicated.

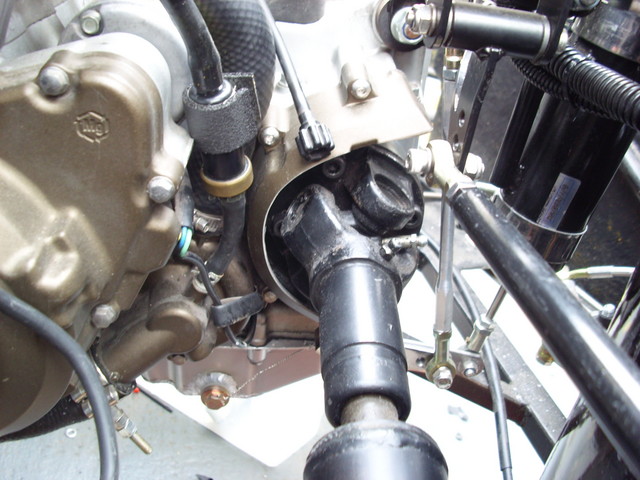

Rescued attachment 150105 005 small.JPG

Today I looked at my engine, and I need something like 20-30mm spacer - because of cooling tube near the sprocket (something like

"sprocket-adaptors" adapter design).

So I will made flange on lathe, and then weld original sprocket to it. I will make taper like you or just use sprocket's edge to fit it

centered.

Lucas

|

|

|

loony

|

| posted on 25/2/12 at 02:40 PM |

|

|

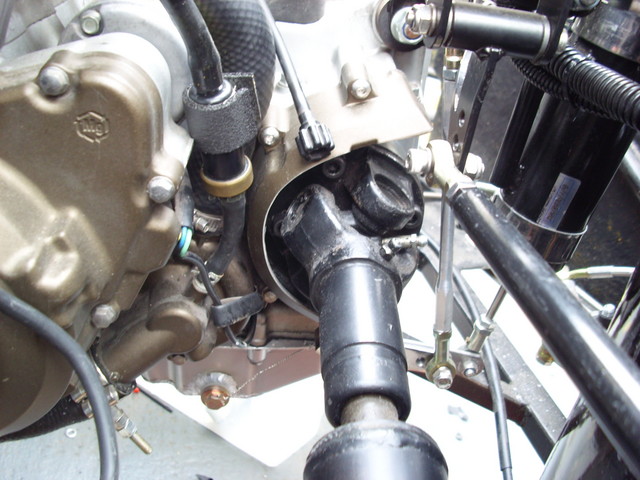

Or maybe I shouldn't worry about it:

Prop adaptor fitted

It's 40inches's prop adapter - it's tight, but it fit. Unless it isn't Ford flange...

[Edited on 25/2/12 by loony]

Lucas

|

|

|

Rogthebandit

|

| posted on 27/2/12 at 08:42 PM |

|

|

quote:

Originally posted by matt_gsxr

I assume you have tried these guys?

http://www.sprocket-adaptors.co.uk/

--------------------

Ya I 2nd this as these guys sent me an adaptor with no problems and it's top quality. Highly recommended

Cheers

Rog

|

|

|

loony

|

| posted on 12/3/12 at 11:30 AM |

|

|

Last progress...

From this:

ZX9R sprocket before

To this:

ZX9R sprocket after

Now I need flange/adaptor to fit my sprocket...

[Edited on 12/3/12 by loony]

Lucas

|

|

|

40inches

|

| posted on 12/3/12 at 01:25 PM |

|

|

quote:

Originally posted by loony

Or maybe I shouldn't worry about it:

Prop adaptor fitted

It's 40inches's prop adapter - it's tight, but it fit. Unless it isn't Ford flange...

[Edited on 25/2/12 by loony]

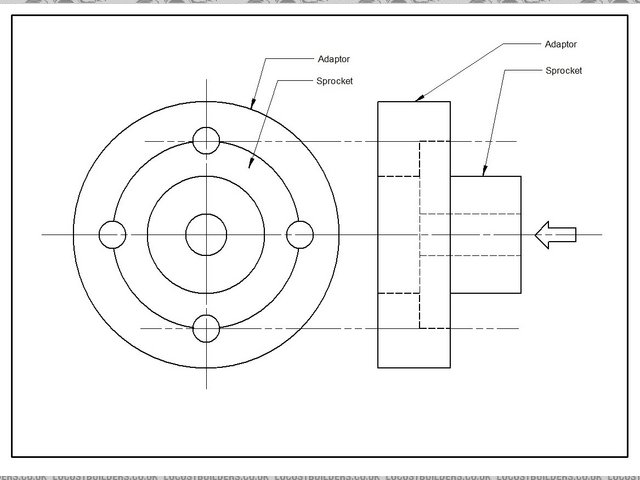

I got mine from Mach1. It is the bike sprocket with the teeth machined down to the centre of the holes in the flange,

the adapter part is machined to fit over the sprocket and the holes when drilled make sure the adaptor can't slip.

Hope this makes sense.

Quick drawing to hopefully make things clearer

Sprocket adaptor2

[Edited on 12-3-12 by 40inches]

[Edited on 12-3-12 by 40inches]

|

|

|

loony

|

| posted on 17/1/13 at 04:21 PM |

|

|

Update...

Here's final result: SAE1140 DIY sprocket adaptor

Ready

TIG welded

Total (lo)cost: 22GBP

Lucas

|

|

|

clairetoo

|

| posted on 17/1/13 at 04:46 PM |

|

|

Not quite the same thing - but back when I was building/racing drag bikes , I used to make my own offset sprockets - anything up to 4" !

I heated up the sprockets to red heat , left to air cool , then machine/weld as needed - I then just popped them to a local heat treaters for

re-hardening .

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

chrism

|

| posted on 19/1/13 at 04:09 PM |

|

|

quote:

Originally posted by loony

I know it's too long. But tks's engine was V2 so it was complicated.

Rescued attachment 150105 005 small.JPG

Today I looked at my engine, and I need something like 20-30mm spacer - because of cooling tube near the sprocket (something like

"sprocket-adaptors" adapter design).

So I will made flange on lathe, and then weld original sprocket to it. I will make taper like you or just use sprocket's edge to fit it

centered.

Ive seem ones like this done years ago when bike engines were just starting to be used, and they failed very quickly, usually taking out something on

the engine. Any slight misalignment on the sprocket end would be exagerated greatly on the prop end.

I would definately not recommend using an adaptor like that.

----------------------------

A little hard work never killed anyone, but why take the risk!

-----------------------------

|

|

|

ian.stewart

|

| posted on 1/4/14 at 09:46 PM |

|

|

quote:

Originally posted by clairetoo

Not quite the same thing - but back when I was building/racing drag bikes , I used to make my own offset sprockets - anything up to 4" !

I heated up the sprockets to red heat , left to air cool , then machine/weld as needed - I then just popped them to a local heat treaters for

re-hardening .

Claire, don't suppose you have any pictures of the extended sprockets, I think I will have to make an extension sprocket, Im guessing I will

need to hang a support bearing somewhere off the clutch cover.

Something different, Very different..............

|

|

|

clairetoo

|

| posted on 1/4/14 at 10:20 PM |

|

|

Sadly no photos to hand - this was back in the days before digital cameras and the internet.......

Everything was made by hand - and drawings where no more than pencil sketches on scraps of paper.......

I've dug out a few pictures showing the sort of bearing supports I used to make - I'll scan them and pop a couple up tomorrow (bit late

now.....off to bed ! )

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|