Bob C

|

| posted on 26/3/07 at 08:25 PM |

|

|

If you have 2 UJs on a propshaft, with parallel end flanges, then the non-linear transfer angles can cancel out. But on a BEC split prop you have 3 so

it won't. It can only possibly cancel if one of the joints is straight (which will wear it out quickly due to 'brinelling'

I'd say use a doughnut for the straightest of the joints - cheaper than a TRT (but a bit tricky to fit in a locost tunnel), soaks up minor

length variations and every sierra prop comes with one built in!

cheers

Bob

|

|

|

|

|

JoelP

|

| posted on 26/3/07 at 09:25 PM |

|

|

are you sure you're right there bob, as far as i can see if the ends are parallel then it doesnt matter what happens in the middle. Shame i dont

have lego any more to test it!

How fast would brinneling realistically were the joint out? Is it a real problem in anticipated kit car mileage?

|

|

|

ChrisGamlin

|

| posted on 26/3/07 at 10:06 PM |

|

|

Hi Pete

If the fact that the flanges are not parallel really is your reasoning, why did you not at any point simply say "you'll need it in the

front if your prop flanges aren't parallel", and why argue that its the reason my bolt came loose when you know my flanges ARE

parallel?

I apologise if you think my initial comment was patronising, it certainly wasnt intentional which I hoped was obvious given my second reply to you

which was plainly written in a non confrontational way, despite what I thought was a fairly abrupt reply from you.

quote:

I can't see the reason for a slider in the rear however obvious it is to you and you have made no effort to explain to me just told me I am

wrong and put me in a negative frame of mind

Not true, I clearly gave you my reasoning why I think its a bad idea to have it in the front (which are completely unlrelated to your reasonings for

having it there), and given that I accepted your explaination that the rear of the prop has enough movement for a live axle without slider, Im clearly

no longer saying its NECESSARY in the rear of the prop. What we hadn't cleared up until now is why you feel its paramount to fit it in the front

given the amount of flex in the centre bearing, up until now haven't explained anything other than to say the UJ will be destroyed without it,

so it would appear that you're the one expecting me and everyone else to accept your view as gospel without any reasoning behind it, not me.

Back onto the technical side of things, I would think (and anyone please correct me if its wrong) virtually all the vibration induced by prop phasing

will generally end up in ocillating vibrations making the prop "whirl" like a skipping rope, not fore-aft vibrations - so if this is the

case I don't see how the slider would help damp these? In addition the sliding joints Ive seen appear to have far too much stiction / damping to

damp high frequency vibrations like that even if they were fore-aft.

I guess it boils down to the fact that I am still of the opinion that the slider's primary role is simply being there to accomodate tolerences

in manufacture and movement of the engine / gearbox due to rubber mounting, not to dampen an out of balance / out of phase prop.

Chris

[Edited on 26/3/07 by ChrisGamlin]

|

|

|

Bob C

|

| posted on 26/3/07 at 11:02 PM |

|

|

With 2 UJs you have to line up the yokes on the middle section. Which bits would you line up with 3??? 'cos if you line up both middle sections

the end ones would end up at 90degrees, which would be totally wrong if the middle joint were straight & the other 2 at an angle - it just

don't work with 3 UJs!!

I think the "wearing straight" thing is not too important - at worst you end up with a tiny bit of backlash, nothing compared to the diff

& CVs on the driveshafts! I've seen it on an aincient prop (off a spit I think) - the joint seemed to 'click into position' in

the straight ahead state.

ATB

Bob

|

|

|

Peteff

|

| posted on 27/3/07 at 12:02 AM |

|

|

why did you not at any point simply say "you'll need it in the front if your prop flanges aren't parallel",

Because that was the obvious point of his question as illustrated by his diagram. I didn't therefore think it necessary.

I could have just as easily used "can see", or "accept". which would have worked better. The only reason you gave for putting

it in the rear was because it might let go at the front which just illustrates a lack of confidence in the prop.

The link in 02G2s post illustrates prop principle and the reason the sliding joint is needed in the front is to allow the prop some movement when the

knuckle of the centre uj is on the inside of the centre angle pushing the front of the prop towards the engine and pulling it on the outside. I think

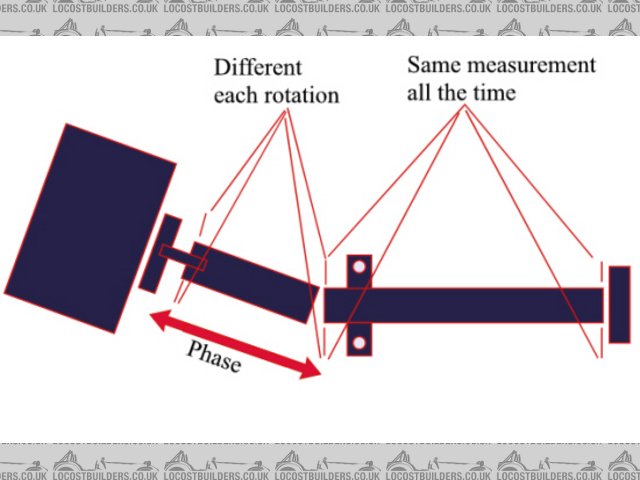

Bob is using the same logic as me in saying that the centre angle cannot be cancelled out on a two piece prop, the joint is phasing. The slider is a

bodge to allow this movement to go somewhere other than back into the engine end of the prop.

According to the vibrate website

On vehicles with two piece propshafts there is an odd joint. The working angle of the odd joint should be kept below 1/2 degree and above zero

degrees. This is because there is not a companion U-joint. Think of the front piece of a two piece propshaft as being an extension of the transmission

output shaft.

1/2° is not practical in my application so now I may have to rethink the engine position

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Peteff

|

| posted on 27/3/07 at 09:28 AM |

|

|

And now my theory

The designer will have specified a material rigid enough to stop the prop from whirling like a skipping rope which is why it is made in two pieces to

keep the thickness down, not to get round a corner like we use it on a Locost, so the movement will be translated into fore and aft and be operating

at an angle to the centre bearing.

Rescued attachment propphase.jpg

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

xico_ze54

|

| posted on 27/3/07 at 10:05 AM |

|

|

I forgot to tell you I'll use a Sierra 3.15 fixed diff.

the discussion is very nice indeed, great theories but no unanimous conclusions at all.

so what kind of way must I follow?

cheers

Amadeu

|

|

|

Bob C

|

| posted on 27/3/07 at 10:10 AM |

|

|

Pete - there is no axial movement as a UJ rotates, the vibration is purely rotational. (provided the 2 rotational axes of the spider intersect, which

they always do in a prop, sometimes don't in a socket set!).

cheers

Bob

|

|

|

ChrisGamlin

|

| posted on 27/3/07 at 10:49 AM |

|

|

quote:

Originally posted by Peteff

Because that was the obvious point of his question as illustrated by his diagram. I didn't therefore think it necessary.

I could have just as easily used "can see", or "accept". which would have worked better. The only reason you gave for putting

it in the rear was because it might let go at the front which just illustrates a lack of confidence in the prop.

To be fair the chap originally asked the question if he could do it this way, and by the time we'd got into a discussion about it, we'd

already covered various different options including having them parallel, so I don't think it was particularly obvious your ongoing stance was

only related to the original drawing. It also doesn't explain why you thought that the lack of slider in the front was the culprit for my bolt

loosening given mine is different to that, but anyway Im happy to let that drop.

Your second sentence above was the part you seemed to misunderstand because I didnt suggest putting it in the rear due to a lack of confidence in the

slider failing in the front, its a lack of confidence in the prop flange retaining mechanism on the engine which was only ever designed to hold a

sprocket, not a heavy flange plus a prop hanging off it. My reasoning had nothing to do with the prop itself, it simply uses the lack of slider as a

safety net if the flange bolt were to undo.

Anyway, thanks for putting in the effort with the diagrams etc, I do understand what you're saying but I still think that UJ angle changes

affect the speed the prop rotates, not its length (hence it not being a CV - Constant Velocity joint), which seems to be backed up by what Bob has

said, and in this technical article by Bailey Morris which doesn't mention length

change, just angular velocity change. Even if there were axial movements though, I can't see how the heavily damped / high stiction slider would

be able to damp movements at 100Hz+ which is what would be experienced with a prop rotating at 6-7000rpm, or why simple 2 UJ props also have sliders

in them but again Im happy to agree to disagree.

cheers

Chris

|

|

|

ChrisGamlin

|

| posted on 27/3/07 at 11:07 AM |

|

|

Amadeu

As you can probably guess, its quite a complicated subject if you want to get everything "textbook". In reality most installs are a

compromise of some sort but what's been discussed about balancing two of the UJ angles and keeping one almost straight is a good starting

point, so either like mine (with the rear UJ almost straight) or with the front UJ almost straight with the rear two cancelling each other out should

give acceptable results. If you want to look further into the technical stuff, have a look

here.

As for the slider, you've seen the arguments for and against positioning it at the front so I'll leave that one for you to decide on.

cheers

Chris

|

|

|

G.Man

|

| posted on 28/3/07 at 06:37 AM |

|

|

so, I have to ask this.. why not use a cv joint instead of a universal?

Opinions are like backsides..

Everyone has one, nobody wants to hear it and only other peoples stink!

|

|

|

ChrisGamlin

|

| posted on 28/3/07 at 09:40 AM |

|

|

From what I understand, its very hard to make / find a CV joint thats capable of rotating at ~7k rpm, obviously as a driveshaft they are rotating at

1/3 to 1/4 that speed.

|

|

|

Bob C

|

| posted on 28/3/07 at 12:28 PM |

|

|

Quite a few cars do use a CV in the prop, I know rover SDI did for example. Also the later front engined single seaters used CVs because of the

extreme prop joint angles needed to negotiate the driver's arse (the rzeppa joints from mini driveshafts)

I'd recommend a sierra donut for the straightish joint - then you won't need a TRT. Why has no-one else done this, it works a treat!

Bob

Bob

|

|

|

G.Man

|

| posted on 28/3/07 at 01:05 PM |

|

|

quote:

Originally posted by Bob C

TRT. Why has no-one else done this, it works a treat!

Bob

Bob

I have been saying that for ages

Opinions are like backsides..

Everyone has one, nobody wants to hear it and only other peoples stink!

|

|

|

ChrisGamlin

|

| posted on 28/3/07 at 01:14 PM |

|

|

Is it not too big to fit in some transmission tunnels?

|

|

|

G.Man

|

| posted on 28/3/07 at 01:37 PM |

|

|

To be fair, looking at the top pic, I think it would be a lot easier to route the steering column differently than the propshaft?

Many have router the column around a V8 so dont see a Bike engine could be harder?

Opinions are like backsides..

Everyone has one, nobody wants to hear it and only other peoples stink!

|

|

|

xico_ze54

|

| posted on 29/3/07 at 10:36 AM |

|

|

quote:

Originally posted by G.Man

To be fair, looking at the top pic, I think it would be a lot easier to route the steering column differently than the propshaft?

Many have router the column around a V8 so dont see a Bike engine could be harder?

its not impossible, but very difficult because the great concentation of elements on the left of the chassis.

I made (almost done) a Locost with an old Toyota 1200cc with much mechanical elements on the left side and I tell you it is was an hard job to pass

the steering column through that site, plus I had to rotate slightly the engine to the right side.

(see http://www.viseudesign.com/Sevenesque-04.htm)

|

|

|