clutch_kick

|

| posted on 7/2/07 at 12:49 PM |

|

|

no I doubt that i could use the stock MAP sensor. That would be a 1Bar sensor, I would require a 2 Bar sensor which would be fine up to about 14psi,

Although to keep costs reasonable I guess i would stick to about 10 psi only.

|

|

|

|

|

clutch_kick

|

| posted on 7/2/07 at 12:51 PM |

|

|

quote:

Originally posted by jkarran

I'm planning a welded ally plenum that will also be the top tank of an integrated intercooler. I've made all the bits but I'm still

psyching myself up to buy a tig setup to put it together  That all sits on the standard throttle bodies, the only mod I plan to them is connecting

the flat slide diaphragms to manifold pressure. That all sits on the standard throttle bodies, the only mod I plan to them is connecting

the flat slide diaphragms to manifold pressure.

Check out the photos I linked to on pg 1 for a better idea how I'm plumbing it.

jk

If there is one big advice i can give you is to avoid an intercooler over the engine, stick it somewhere in the nose, it's worth all the extra

work and hassle. I know what i'm on about, toyota have a bad habbit of sticking intercoolers on engines (GT4 and Glanza)

|

|

|

jkarran

|

| posted on 7/2/07 at 08:15 PM |

|

|

quote:

If there is one big advice i can give you is to avoid an intercooler over the engine, stick it somewhere in the nose, it's worth all the extra

work and hassle. I know what i'm on about, toyota have a bad habbit of sticking intercoolers on engines (GT4 and Glanza)

Cheers for the tip... it was very much my first thought too but I've opted for the 'over engine approach for a few of reasons, it is

however a compromise and I do keep looking at it and thinking 'maybe I should do it differently...'.

The reasoning is thus: Where it is, over the gearbox I can duct a lot of cold air from the nose (seperate from warm radiator air) and bonnet NACA

ducts. I also have room for a shield between it and the 'box. There's room for a fan. Surplus IC heat will go out down the transmission

tunnel & bonnet vents rather than through what will be a hard pushed standard R1 rad and around my engine. The striker also has inboard shocks and

a narrow nosecone already very full of ducting. Other less convincing arguments are that I had an IC core that fits there but not in the nose

The downsides are that it will enevitibly be heavier and more complex with a fan and sheet ally ducts fron the nose. It will enevitibly pick up

some heat from the engine and rad. It will perhaps be prone to embrittlement as it wont be very well mechanically isolated from engine

vibration. The ICs hot air will also flow right around the inlet pipe (but not the filter which will be fenced off and breath through yet another

bonnet vent!).

Does this address your concerns or am I being unrealistic about what can be achieved?

jk

|

|

|

Tralfaz

|

| posted on 8/2/07 at 12:26 PM |

|

|

If you can duct fresh air to the intercooler effectively as you describe, I think it may be a better idea as you will likely have signifigantly lower

'Throttled Volume ' in your system.

Brian

|

|

|

clutch_kick

|

| posted on 8/2/07 at 02:26 PM |

|

|

The whole explanation sounds ok, but it also sounds a bit too over-complicated, keeping in mind that you could do it in a much simpler way. From the

looks of it you will need forward speed to get the air to flow over the I/C or use a Fan(more weight and drain on the Electrics).

It is all down to personal preference, from my past experiences ... I would do what ever is possible, to get that IC away from the engine. When

you're stopped idling in traffic ... it very quickly becomes an interwarmer. Then you will need a LOT of fresh air to cool it off again.

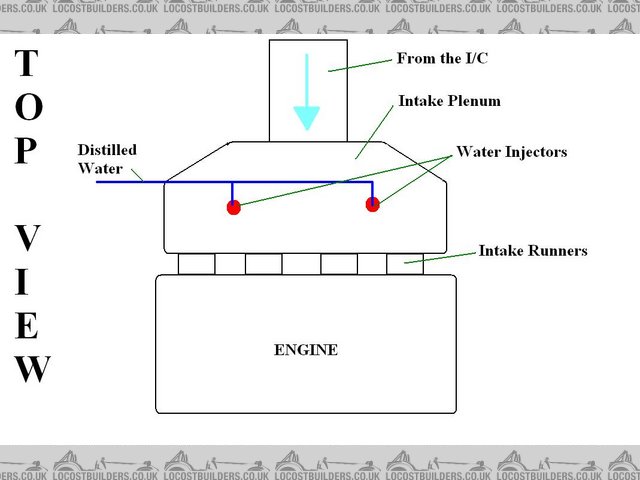

If you do go for the Over engine design ... ditch the fan, and install a Water Injection Unit. That alone drops the intake temps by a good 18degC.

|

|

|

clutch_kick

|

| posted on 8/2/07 at 02:44 PM |

|

|

This would be a simple diagram to show the layout for the W/I. I have bought parts off this company and they are very good.

http://www.coolingmist.com/

Rescued attachment waterinjection.JPG

|

|

|