how to pack an exhaust

welderman - 3/9/08 at 09:45 AM

Right, ive now made my own system but time has come to pack it with wadding, whats the best way to do this fellas (wrap the perf tube or stuff the

stuff into the can?). Im going to weld the end up once its done.

Ta Joe

JimSpencer - 3/9/08 at 09:58 AM

Hi

I really wouldn't recommend you weld the end on.

I normally have to re-pack the exhaust once a season (as the wadding degrades / disappears..) hence most can's have the end cap rivetted on.

Hope this helps

Edit - sorry didn't answer your original question!

Stuff the wadding in

[Edited on 3/9/08 by JimSpencer]

tul214 - 3/9/08 at 10:15 AM

I used a cardboard tube(wrapping paper) as a sleave and wound wire wool around it. I then push the cardboard sleeve over the perf tube in the can and

carefully slide the wire wool off so that it is an even thickness along the perf tube. This, i am told helps protect the wadding from burning away too

quickly.I then use a broom handle to push the wadding in , inbetween the now covered perf tube and the can. I have had the best results when the

wadding is packed, but not too tightly in the can.

As above, do not weld the end on.You will need to re pack as nnd when!. I seal the end with heatproof sealent and use 4 self tapers to fasten the end

on.

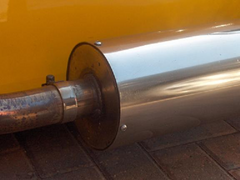

Description

Hope this makes sense

[Edited on 3/9/08 by tul214]

[Edited on 3/9/08 by tul214]

welderman - 3/9/08 at 11:04 AM

Ok, im not going to weld the end on now, just make some adjustments.

So do i use wire wool, of the matting you can buy, sorry about the questions.

02GF74 - 3/9/08 at 11:10 AM

isn't the locost way to use some glass fibre roof insulation stuff?

bimbleuk - 3/9/08 at 11:11 AM

Similar to above except my perforated tube comes off with the end cap. So I wrap stainless wire wool around the tube to create a barrier. Then I use

sheets of E Glass matting from Merlin and wrap this around the wire wool and tube. only about 2 or 3 layers so its snug but not compressed when I push

the tube back in the can. Since I've been running 250+BHP the E Glass has began to melt so I'll experiment with basalt packing for the next

refill.

mad-butcher - 3/9/08 at 07:06 PM

I used these

welderman - 3/9/08 at 08:10 PM

mr butcher, fantastic link mate, your a star