R1 Gearchange lever length?

nitram38 - 26/7/07 at 10:53 AM

As some of you know I am building a rear engine chain drive car.

I am planning on making my own paddle shift. It will be bowden cable that terminates in a trickshifter actuator before it attaches to the gear lever.

I have the splined bit from locoboy but now I need to weld a piece of flat on to attach the rod end on the actuator.

The bowden will attach to the paddle shift about 3" from the centre of the paddle.

Does anyone have an idea how far from the centre of the gearchange shaft the actuator/cable needs to attach?

I want the paddle to move as little as possible so the shifts are not going to interfere with my steering wheel, but I also want them easy to pull

without breaking my hand!

I know that I can drill several holes in the lever to have a play with the settings but what length of bar have you used?

I am just looking for some ideas so photos would be helpful.

Cheers Martin

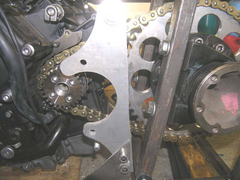

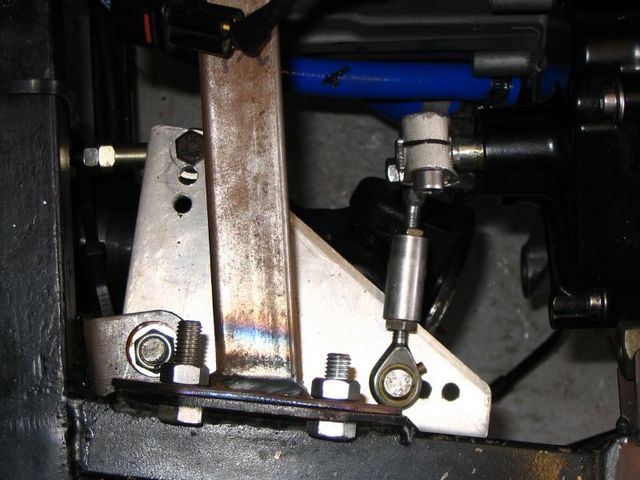

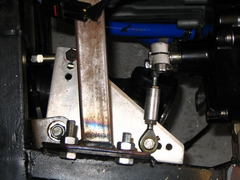

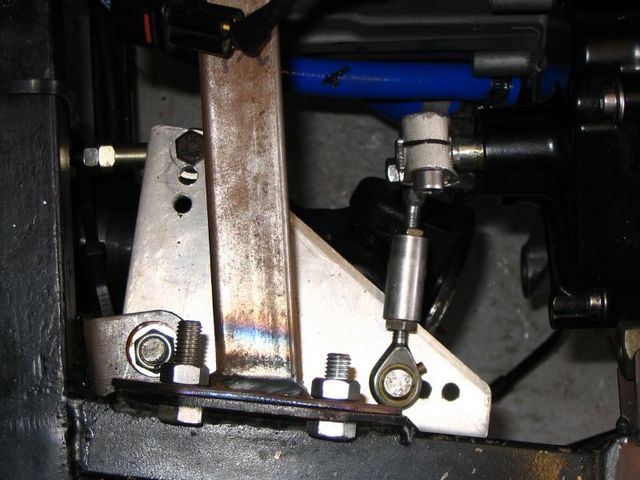

Here is a photo of the gearchange gizmo in the top left:

Description

[Edited on 26/7/2007 by nitram38]

adithorp - 26/7/07 at 03:34 PM

My gearbox lever is 30mm long, rod from this goes to a transfer 90 degree quadrant 40mm from the pivot, rod from this is 55mm from pivot (this is the

bit I played with to get the right movement/feel) and goes to the paddle 80mm from paddle pivot, Paddle is 130mm long from pivot to finger pull. I end

up with about 20mm of movement each way at the finger tips.

I tried equal lengths on the quadrant but it was too heavy. As you won't have the quadrant you'll need a longer gearbox arm to achieve the

same thing 30x(55/40)=41.25 so about 40mm arm if my maths is right !?!

Mine feels good on the few short runs I've done up the steet.

Adrian

[Edited on 26/7/07 by adithorp]

nitram38 - 26/7/07 at 04:22 PM

Thanks for all the measurements, but my set up will not have any changes of direction. You have given me some idea though that the lever can be quite

short.

I think that I will weld a bar onto it and do some measurements and try work it out.

Cheers Martin

lsdweb - 26/7/07 at 05:31 PM

Nitram

Here's a pictre of my lever - it's 6" in length in total. This is connected with a direct rod to the standard R1 lever. The linkage is

pretty direct and feels about right although the rod needs a better support in the middle.

Hopefully this'll help!

Rescued attachment lever.JPG

Wadders - 26/7/07 at 05:37 PM

Hi

To get my trickshifter to work properly i had to make the distance from the spline centre to the end of the lever as short as possible i.e least

mechanical advantage. otherwise even with the trickshifter on it's most sensitive setting it wouldn't work. They seem to need a good hard

tug to operate properly.

Al.

nitram38 - 26/7/07 at 05:55 PM

Wyn, thanks for the picture. I am after a picture of the other end, the lever for the engine.

Mine didn't have the standard one so I need a measurement for the bike end.

If your lever is about 6" then the pivot is about half way, 3", which will be roughly the same distance from my paddle pivot to the

cable.

The bowden I will use will have a sleeved rod at the end which the actuator for the trickshifter will screw onto.

I don't think that it will be a problem.

Cheers Martin

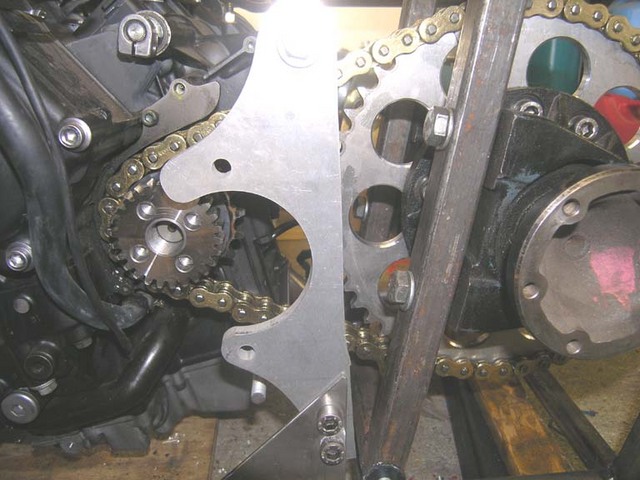

lsdweb - 26/7/07 at 06:17 PM

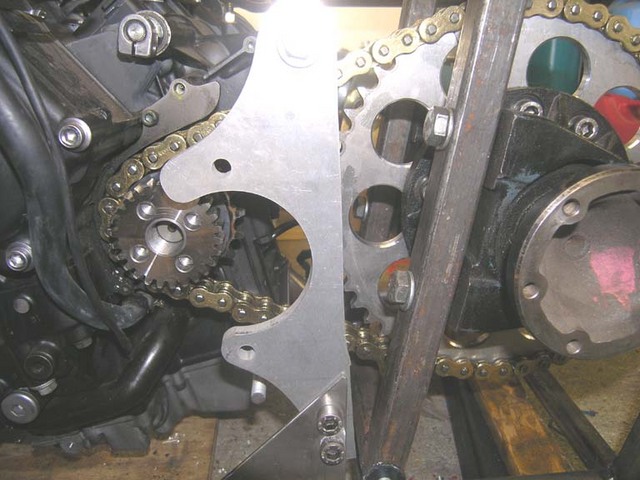

Like this....

50mm from pivot to pivot.

Rescued attachment OtherEnd.JPG

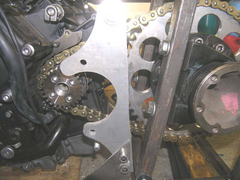

ChrisGamlin - 26/7/07 at 06:27 PM

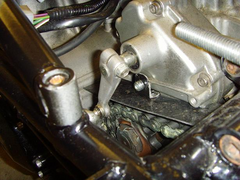

Not sure if its any use or not, but here's the rocker Im using on the stock R1 actuator arm the same as Wyn's, i guess you'd need the

lever measurements as well to make much of it though!

Gearchange rocker top

[Edited on 26/7/07 by ChrisGamlin]

nitram38 - 26/7/07 at 06:56 PM

Cheers gents!

adithorp - 26/7/07 at 07:49 PM

I understood your arrangement was a direct pull/push. So the calculation was to work out the advantage I got from the qudrant and alter lever length

to get a lever to equal this advantage for a stright pull.

As your padlde pivot/pull point is roughly the same as mine then you need 40mm long arm to get the same leverage.

Of course that depends on my dubious maths!

Adrian

nitram38 - 26/7/07 at 07:57 PM

I will make a lever with a 40mm and 50mm centered hole and try both!

chockymonster - 26/7/07 at 08:41 PM

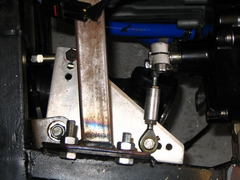

Not the best of pictures I'm afraid, this is a standard R1 gear selector arm.

for scale the rod ends are M8.jpg)

.jpg)