I see it like this, select appropiate gear for the speed required when cruising.

Keep selecting the next gear when engine starts to run out of revs. When no more can be found, you are in top gear.

And the same (but in reverse) to slow down.....

Hi folks - I want to get me a dash display of what gear I'm in - electronics/display not worries, question is - how do I graft microswitches into

the R1 gearbox to decode what gear I'm in?? Anybody know where to look?

Cheers

Bob C

Have a look at the digi datatool gear indicator. They cost about £60 and fit any bike.

datatool

[Edited on 4/8/03 by MK9R]

[Edited on 4/8/03 by MK9R]

hi dont know if this is any use but Data Tool do a electronic gear display that just wires in to the loom,but you may need to get the back wheels off the ground just to go through the initial set up of the gears- £59

Of course - that's the wqy to do it. What was I thinking of with microswitches in the gearbox........

How does it know what gear your in? My gearchange is purely mechanical

Steve

quote:

Originally posted by coozer

How does it know what gear your in? My gearchange is purely mechanical

Steve

Not wishing to wind anybody up, but why do you need to know what gear you are in? Or is it just for posing?

I see it like this, select appropiate gear for the speed required when cruising.

Keep selecting the next gear when engine starts to run out of revs. When no more can be found, you are in top gear.

And the same (but in reverse) to slow down.....

Exactly, thats the point Stu, with a BEC you never run out of revs, and so keep trying to upshift when no gears are left to select, plus sometimes

with the sequential box, you pull up to a junction thinking your in first, and then find your not . A visual aid just helps!

Al.

i]Originally posted by Stu16v

Keep selecting the next gear when engine starts to run out of revs

Surely you only try for another gear once?

Until you are used to the car that is, and then you would know you were in top gear, by comparing revs/speed.

P.s. I've already owned one BEC, and will have another when I can arsed to finish my Westie.....

P.p.s. Still good pose value though...

[Edited on 10/8/03 by Stu16v]

I think the really advantage is when changing down the box when coming to a bend, you shouldn't go through the box using the engine to slow you

down as it will wreck the clutch, and the last thing you want to do is shift down 3 gears, expecting to be in 2nd, let the clutch out and you are in

1st

Just my observation from riding bikes, saying that, i never had one on my bike

1) for the pose yeah cool baby wow!

2) in a normal car I'm forever trying to find another gear when I'm already in top - this will only get worse in a BEC...

3) on a bike I have some kind of mental block about finding neutral - perhaps it's me size 13 feet....

4) In a car I'm sure I use the knob position to tell me what gear I'm in (OK settle down now) & thought I'd want to have that

feedback

I've put the logic into my dash design (VHDL) & it does the biz nicely on the simulator - maybe I'll post the PCB layout & see what

you lads reckon

Also note this system won't tell you what gear your in while idling with the clutch in - I'm undecided whether to display "1" or

"c" at this condition (got "n" for neutral and "r" for electric reverse)

Bob C

Driving on unknown roads or tracks would be easier in a BEC if a GPU is fitted, as it can be difficult to tell which gear you're in.

It's not like a car, where you change down through the gears, and the relative position of the gear stick determines and also indicates which

gear is engaged.

Tracks and roads that are familliar are a different story, as you're more inclined to follow habit.

As MK9R points out, braking with a bike engine is a no-no, and as you're nudging the stick forwards in a single plane, it's easy to both

mentally and physically miss a gear.

Just remember when you wire the GPU to your reverse switch, to also wire it through the neutral switch to prevent selecting reverse in any position

other than neutral.

![]()

As MK9R also points out, bikes rarely have gear indicators....

I suppose they are a very good learning aid, helping the driver get used to the car (just as a learner driver glances at the gear stick to see what

gear he/she is in), But once you come to grips with the machine I'm sure that it will become pretty much irrelevent.

If you can look down to see which gear you are selecting for the next corner, whilst braking hard, whilst fighting for position, you aint trying hard

enough....

ratio difference between 5th and top on the R1 box is just 7.6% - these things are really close ratio. I reckon if you know what gear you're in

it's because you've counted shifts. (hmm - idea there to get round the clutch in problem!) Also the "toy car" won't get used

that often - I need an indicator!

Cheers

Bob C

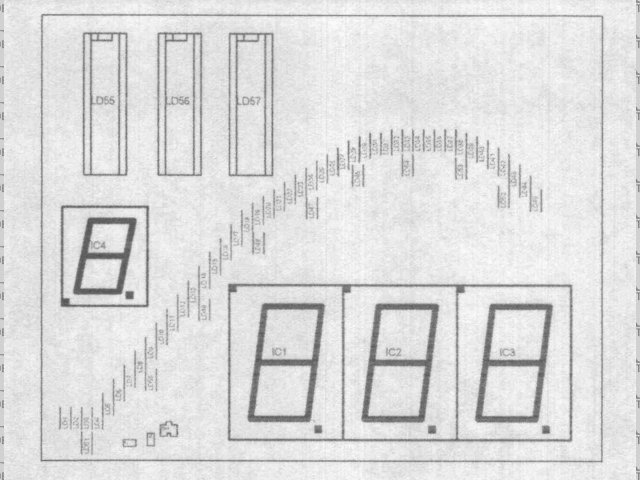

here's a 1st stab at dash layout -

The line of LEDs is tacho bargraph - the odd LEDs under are for scale, 1 3 5 7 8 9 10 11 & 12krpm. The big 7seg. LEDs are mph & the small

lonely one says what gear I'm in. The 3 bargraphs at the top are for fuel oil press. and temp.

Other single LEDs will include main beam & maybe indicators.

Pushbuttons for select reverse and brighten/dim display

Ouputs to drive LCD totalisers for odometer & trip.

Whaddya reckon??? Should fit in a V small FPGA so main cost is 7 segment displays

Cheers

Bob C

Rescued attachment dashlayout.jpg

any idea of costs and applications bob?

Could you make the picture a bit larger, i am struggling to see the detail!

[Edited on 14/8/03 by MK9R]

Sorry about picture size - I'll try harder next time.

Based on programmable logic, so I'm building scaling factors etc into the logic, making it programmable in place makes the logic WAY more complex

+ you have to build in provision for entering the data, expense everywhere you look. The logic is configured from a wee 8 pin PROM so it IS a

programmable system but effectively the designer has to compile to order. Also rpm scaling and power curve are right for the Yam R1, nothing else

(although would be reasonable for anything with peak power at 10krpm) I'm guessing at around 80 to 100 quid a time assuming I'd have to put

a couple of hours of computer work into each one. Plus I'd have to source a prop sensor of course & drive tank & oil pressure sensors.

Might be worth me considering a couple of variants for 'blade & maybe another if it would make me some cash - I'll have done all the

hard work on mine!

Let's see if there's any demand (at all)!

cheers

Bob C