All the best

For use with electronic systems such as those from Kliktronic?

Thinking of getting this and changing the buttons to microswitches and then making some sort of paddles to attach to the steering wheel.

Any suggestions?

Cheers

Mike

YES!! Was just thinkin that exactly!! Was gonna mount the paddles onto the boss so they will turn with the steering wheel. Let me know how u get on

All the best

hi,

I have been building thes for a bit controled by a pic I have sold a couple to pepol on thes bords (thay where 50 quid wit no solinoids). I am swaping

infor mation with a couple of others as well with hoping that the information helps them buid systems.

however on more recent news I have just finised develoment on a multy laer surfece mount PCB witch will become the hart of my new system witch will

incorporate a stering weel dash system as well. for full on control and gearbox gigery pokery.

however building a simaple system is not complicated and can be acomplised with a cople of relays switces and solinoid

blake

I recently bought a Kliktronic for my R1 build and am hoping to do exactly what you suggest. I stole the aluminium paddles from my PC steering wheel

and as soon as I have chosen which boss & steering wheel I'm going to use, I will try to work out how to mount them and get them to pivot. I

was thinking of fixing a piece of CF between the wheel and the boss, which would act as a 'platform' for the paddles and microswitches.

I found out about some hardcore PC gaming wheels which use much the same design and I think look great:

Click Here

Looks like the paddles are pivoting via some springs?

Mikey,

I am in the process of doing exactly what you are suggesting with my MK GT1.

I have gone for a Stuart Taylor paddle shift system, which I will use with micro, switches rather than the cable normally used.

The Stuart Taylor paddle system is a quality bit of kit and see no major problems in using it with an electric changer.

Ian Gray was very helpful when I phoned him, and since you are building a ST Locoblade, it would be worth giving him a call.

Mike

Cheers guys

I have thought about using something off a games wheel but dismissed it as being flimsy. May take another look at a few and see what i can find.

The ST one as i understand it is fixed and doesnt turn with the wheel.

I am thinking of making it from aluminium plate and designing a pivot system to attach it to the wheel and fit the microswitches in there

somewhere.

I am not confident in building my own electronics and dont understand the use of PIC! If i was to do this, i would want it to work on the principle

that a simple pull on the paddle would momentarily kill the ign and push the solenoid, this being adjustable to give the fastest change possible

without letting go of the paddle to return ignition and release the solenoid. If this can be done with a PIC i would be very interested.

I have been looking for solenoids and cant find any double acting ones like the ones used in the Kliktronic system, i like that as it looks very neat

and you are not playing around trying to get 2 solenoids to work opposite each other.

Thanks for the suggestions

Mike

You could always use one of the Fast & Furious style wheels with 2 red buttons for up & down

<Runs away and hides>

hi,

mikey when I have done it I use the PIC as it is a like a processor and hence can be used to control every thing. you could do it thought any number

of other methods however I am a programmer and then hard where person so I like programmable solutions. This coupled with the fact that if I design a

programmable solution I can change the soft where and change the operation where as if I build it in hard where you have less flexibility.

Blake

quote:

Originally posted by Mikey G

I have thought about using something off a games wheel but dismissed it as being flimsy. May take another look at a few and see what i can find.

hi

I have used the solinoid of the side of a saab starter motor as fitted to a 1990 900, the same stater motor is fited on others 900 however it is

harder to remove (it is a BOSH part). faling that looking through a RS or BOSH catolog will show lots of other sutoble solinoids for a lot less than

the klicktronics one (do thay sell the solinoid by its self?).

if you are making padles it is woth thinging about the presuyre you are exserting throught the leavereg of the padle on to the switch as you may well

kill the swittch however ther are some small foot operated switche witch have a nice feal and will take the load.

Blake

double post

[Edited on 9/12/04 by ceebmoj]

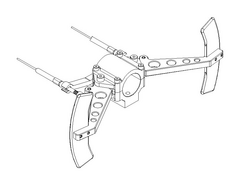

Paddles as fitted to my car, no exactly locost.

It is a proshift system and works very well.

Tony.

Rescued attachment IMG_3311.gif

Subscribing to this because it looks like a neat idea to try  Question for anyone running a setup like this: are the upshifts and downshifts quick,

or is there a noticeable delay while that shaft extends or contracts?

Question for anyone running a setup like this: are the upshifts and downshifts quick,

or is there a noticeable delay while that shaft extends or contracts?

I've used both buttons on the steering wheel in unison with an electronic shifter and also paddles connected to the 'box with cables. The

Buttons look flash and basically change the gears as quick as you can press them. The paddles and cables are just as quick as they're very direct

acting. They're also a fraction of the weight of of one of the heavy Klicktronic ones, and a fraction of the cost. They're also a lot easier

to set up and fine tune.

Horses for courses.

I would recommend a manual mechanical backup lever if you do decide on an electronic shifter. If the thing goes tits up on a bike, it's no big

deal; you just hook the lever with your toe. If the thing goes in a car, it can be embarrasing at best, or dangerous at worst.

There are pictures of the buttons on my steering wheel and the Klicktronic on my site. Not sure if the paddles are shown on there too.

How easy is it to find neutral with an electronic shifting mechanism? Or is it better to move over to the mechanical lever for that?

quote:

Originally posted by Ferrino

How easy is it to find neutral with an electronic shifting mechanism? Or is it better to move over to the mechanical lever for that?

This is the kinda style im going for

[Edited on 11/12/04 by Crazy Jay]

So Crazy Jay, you've got a capital H shaped bit of aluminium. WTF does that do?

Slumming it again Syd? I still reckon you're a bastard.

Alright then, for the not-so-intelligent amongst us, is it a type of sprung, flexible paddle, or just somewhere to locate shifter buttons?

Looks to me like it pivots at centerline. You can see a rod end and control rod attached to the right side.

T

Keep it simple theory. I subscribe to that whenever possible. What kind of effort does it take to shift gear and can you alter it with the leverage ratio if you want to?

I'd like to put an electronic shift like 1 of the above on my indy but woud like it to blip the throttle on the way down the gears. Has anyone

done this?

thanks

Mark

missed this off the above post

Also i'd like it to kill the ignition on the way up the gears so i can keep my right foot flat to the floor. Would also be nice if i could have

a setting to make the shift occur when a certain rpm is reached.

thanks again

Carnut

It occurs to me that a stepper motor would be a better solution than a solenoid. Stepper motors are very reliable, even in extreme environments such

as the engine compartment. Controllers are simple to control and easy to obtain.

My idea is to setup a lookup table with the positions of the different gear positions then have the motor go to them. In priciple, this solution

would also be applicable to non-bike 'boxes, although more than one motor/controller may be required.

There must be something wrong with this idea, as I am unaware of anyone trying it, yet it is so obvious.

Cheers

KT

Yes, the problem is the speed of steppermotor

The (good) switch-shift / paddle shift systems uses electric motors running 30K RPM ...

quote:

Originally posted by CooperLight

Yes, the problem is the speed of steppermotor

The (good) switch-shift / paddle shift systems uses electric motors running 30K RPM ...

Just home from work

That picture is a stuart taylor made paddleshift, was just showin the kind of design i will be going for.

Altho ST use a manual shift im gonna get the electronic system and mount a couple of micro switches. Another difference is im gonna mount the paddle

to my steering boss so it moves wit the wheel

Is it colmaccoll who mentioned he makes the electronic shifters??

quote:

Originally posted by Tralfaz

Looks to me like it pivots at centerline. You can see a rod end and control rod attached to the right side.

T

quote:

Originally posted by carnut

I'd like to put an electronic shift like 1 of the above on my indy but woud like it to blip the throttle on the way down the gears. Has anyone done this?

quote:

Also i'd like it to kill the ignition on the way up the gears so i can keep my right foot flat to the floor.

quote:

Would also be nice if i could have a setting to make the shift occur when a certain rpm is reached.

quote:

Originally posted by krlthms

It occurs to me that a stepper motor would be a better solution than a solenoid.

quote:

Originally posted by Crazy Jay

Just home from work

That picture is a stuart taylor made paddleshift, was just showin the kind of design i will be going for.

Altho ST use a manual shift im gonna get the electronic system and mount a couple of micro switches.

quote:

Another difference is im gonna mount the paddle to my steering boss so it moves wit the wheel.

Holy poo thts a nice design!! That is very similar to one of my designs

Is the car rack & pinion Rorty? i considered a similar design, but convinced myself it wouldn't work due to the cables getting tangled

etc.

I guess on a buggy there's very little steering wheel turn, lock to lock.

Al.

quote:

Originally posted by Wadders

Is the car rack & pinion Rorty? i considered a similar design, but convinced myself it wouldn't work due to the cables getting tangled etc.

I guess on a buggy there's very little steering wheel turn, lock to lock.

Al.

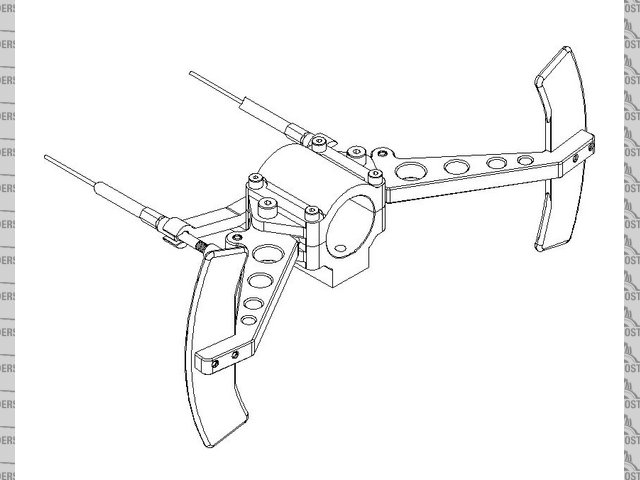

heres one for you crazy jay. its a simple design for a shifter for electric shift

[img][/img]

nice

hi,

the plus points of an eletronic system should not be over looked I gues it just comes down to where youer skills are though. as for finding nutral yes

it can be problematic for a basic systems we have dicused hear however if you use any one of anumber other actuators stepper motors, solinoids,

umatics it is an esy problem to solve. for me the advantages come when the system starts to get involfing i.e. if you have a lap memory in youer

system so the car knowes what is coming next and can preper i.e. alowing revs to get slightly hier on one strait to prevent an up shift at the very

end of the stright. alowing pre selection for the down shift in to the breaking zone. equaly fule econimy and engin life/power can all be tuned in to

the system. I gues that this is maby a bit exsesive for a locost however for a track car maby it is wroth it. can you gues what i do for a living?

blake

[img][/img]

Here is a very nice Solenoid Operated Gearshift DIY project

http://biketransplant.tripod.com/solenoid_shift.htm

quote:

Originally posted by ceebmoj

hi,

the plus points of an eletronic system should not be over looked I gues it just comes down to where youer skills are though. as for finding nutral yes it can be problematic for a basic systems we have dicused hear however if you use any one of anumber other actuators stepper motors, solinoids, umatics it is an esy problem to solve. for me the advantages come when the system starts to get involfing i.e. if you have a lap memory in youer system so the car knowes what is coming next and can preper i.e. alowing revs to get slightly hier on one strait to prevent an up shift at the very end of the stright. alowing pre selection for the down shift in to the breaking zone. equaly fule econimy and engin life/power can all be tuned in to the system. I gues that this is maby a bit exsesive for a locost however for a track car maby it is wroth it. can you gues what i do for a living?

blake

Well this is all great stuff

For the sake of a few quid i'm going to build a simple control circuit over xmas, then i need to find a solenoid or 2, finally after testing my

system using buttons i'm gonna make a paddle shift of some sort. all in i should be able to do the lot for less than £100 depending on how i

do/make the paddles

Mike

I checked this site 6 months ago and contacted one of the three guys. He said he wansn't involved in kit cars anymore.

This seems difficult to make work properly even if it looks pretty simple at first sight..

[Edited on 16/12/04 by Aloupol]

Rescued attachment Shift electrique.JPG

quote:

Originally posted by Crazy Jay

Is it colmaccoll who mentioned he makes the electronic shifters??

quote:

Originally posted by Rorty

quote:

Originally posted by Crazy Jay

Just home from work

That picture is a stuart taylor made paddleshift, was just showin the kind of design i will be going for.

Altho ST use a manual shift im gonna get the electronic system and mount a couple of micro switches.

That makes more sense.

It looks very clumsy. How does it feel? How does it pivot in the centre?

quote:

Another difference is im gonna mount the paddle to my steering boss so it moves wit the wheel.

I designed a paddle shifter for one of my cars which clamps to the steering shaft between the steering wheel and the steering bearing (so it obviously rotates with the wheel).

It uses 6mm pull rods (or cables, depending on engine orientation) and cable-type balljoints. It "snicks" the box nicely into gear.

I don't have any photos because the people at the factory aren't much use with a camera.

quote:

Originally posted by colmaccoll

quote:

Originally posted by Rorty

... clamps to the steering shaft between the steering wheel and the steering bearing (so it obviously rotates with the wheel).

It uses 6mm pull rods (or cables, depending on engine orientation) and cable-type balljoints.

Rorty, Does that design mean that when you pull one paddle the other one moves away and vice versa?