Prop shaft?

Gripenland - 17/4/04 at 03:24 PM

It seems to me that most BEC:s use a two piece prop shaft? Why is that? I can understand it if you run a live rear axle. But if you run IRS or De

Dion, why not use a one peace prop?

Peteff - 17/4/04 at 03:44 PM

There will be a lot of weight on the bike output and it will be hard to balance as it will tend to bend in the middle, like a bow.

Mk-Ninja - 17/4/04 at 04:15 PM

Also you would have to alter the transmission tunnel to get a straight line from the output shaft to the diff.

ChrisBradley04 - 17/4/04 at 04:50 PM

You can also make them a lot lighter if you support them in the middle, as each half can be made from smaller bore/thickness tubing.

Regards

Chris

Gripenland - 17/4/04 at 06:19 PM

Thanks for your input guys!

Mayby I'm a bit slow but...

Peteff- Isn't the bike output shaft designed so take the load from the sprocket and chain of the motorbike? To me it seems that radial force is

much higher with a sprocket and chain than the weight of a propshaft? Or am I missing something?

ChrisBradley04- I thought tourque set the dimensions of the tube? Not vibration. Have I got that wrong?

undecided - 17/4/04 at 06:27 PM

they break..believe me you want some kind of centre bearing to hold the bloody thing still because all sorts of nasty things can and do happen when

things spin at 10,000rpm!

Don't let some muppet say you can have a propshaft getting on for 4ft long without it being supported...i did and it snapped....enough said!

Gripenland - 17/4/04 at 06:35 PM

quote:

Originally posted by undecided

they break..believe me you want some kind of centre bearing to hold the bloody thing still because all sorts of nasty things can and do happen when

things spin at 10,000rpm!

Don't let some muppet say you can have a propshaft getting on for 4ft long without it being supported...i did and it snapped....enough said!

Damn, that must have been scary  I sure hope that it all ended well?

I sure hope that it all ended well?

Gripenland - 17/4/04 at 06:47 PM

undecided- You are right. RPM and length kills the prop. Angles are also important.

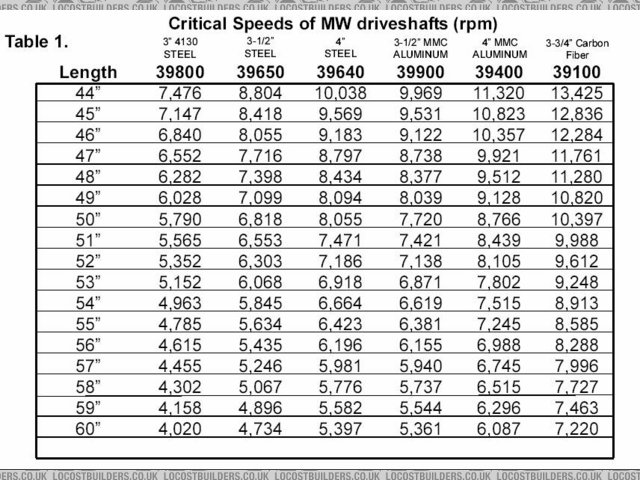

I found this on the web. This is for dragrcing props

Rescued attachment proptable.jpg

Bob C - 17/4/04 at 06:53 PM

Critical speed is speed at which the natural fundamental resonant frequency of the tube (bending in the middle & twanging up & down) equals

its rotational speed. If anything is going to go wrong - this is when it will happen...

Good data, but I can't see material info, just diameter of tube - maybe it's just me not looking properly

Bob C

Gripenland - 17/4/04 at 06:59 PM

Here is a link to the data sheet.

woodster - 17/4/04 at 07:06 PM

PROP SHAFT

Gripenland - 17/4/04 at 07:11 PM

quote:

Originally posted by woodster

PROP SHAFT

???

Peteff - 17/4/04 at 07:35 PM

Like a bow in laymans terms.

To me it seems that radial force is much higher with a sprocket and chain than the weight of a propshaft?

I'm talking about the weight, not the force it exerts in rotation. The sprocket adaptor and propshaft all bear down on the bearing carrying the

output shaft.

woodster - 17/4/04 at 07:35 PM

search ........... prop pic ........ and look in my photo achive ................ or search woodster

Gripenland - 17/4/04 at 07:47 PM

quote:

Originally posted by Peteff

The sprocket adaptor and propshaft all bear down on the bearing carrying the output shaft.

Yes, but when the engine turns the chain it will also load the the same bearing. So to me that inicates that the bearing is designed to handle some

serious loads. Ok the direction of the forces are not the same but still.

Gripenland - 17/4/04 at 07:49 PM

quote:

Originally posted by woodster

search ........... prop pic ........ and look in my photo achive ................ or search woodster

Hmm, I see what you mean  Did you use a one peace prop?

Did you use a one peace prop?

ChrisGamlin - 17/4/04 at 08:13 PM

Someone in the know on the BEC list worked out that to make a single piece prop the length required for a BEC and able to rotate at the speeds

required, it would need to be something like 6" in diameter!

I only know of one person who had a single piece prop in a BEC about 3 years ago, and that too broke catastrophically. If you want to confirm it,

maybe give someone like Bailey Morris a call and ask them their opinion.

Woodsters wasnt a one piece prop, but it had the scariest bodge of a prop flange ever known to man (not done by him I must add!)

Chris

JoelP - 17/4/04 at 10:30 PM

someone said that there is an equation involving the square of the length, apparently this is why length makes things much worse.

Gripenland - 18/4/04 at 03:05 PM

It is obvius that a two peace prop is the way to go unless you go really high tec.

Us vans have very long one peace prop shafts. But they turn at a slow rpm and have a large diameter so they get away with it.

The Volvo XC90 have a 1.5m long single peace propshaft. Its only 60mm in diameter but I guess it turns slow to.

I sure hope that it all ended well?

I sure hope that it all ended well?