bec engine cradle / mounts

a4gom - 25/1/09 at 10:16 AM

I'm fitting a R1 to a narrow bodied westfield, intended making a top and bottom cradle from 1" tube as seems common practice.

I've now sat my engine in where I want it to go and it looks to me like I don't really need to make a top and bottom cradle, all but one

mounting is now within 4 or 5"of an existing chassis member so I intend to make up some small brackets attached directly to the chassis. Is this

good practice, any reason why I shouldn't?

I was intending to use some of these at each of

the six mounting points, they are only 20mm long is that a problem, should I be looking for some longer ones?

I have a selection of 1" box and tube, I'm weight concious but don't want failures, would 1" box with approx 1.3mm wall be strong

enough to cope with weight / vibration or should I be using 2mm wall?

Appologies, lots of questions but I know there will be some guru on here.

[Edited on 25/1/09 by a4gom]

Steve Hignett - 25/1/09 at 10:18 AM

That will be fine, but how do you intend to attach those "bushes" to the mini-brackets?

jacko - 25/1/09 at 10:26 AM

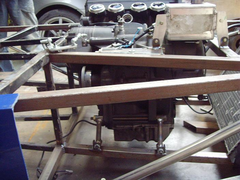

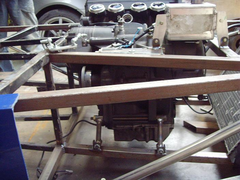

This is how i made the cradle on roadrunners car if you make a cradle it helps stiffen the chassis have a look in his photos zx9r engine

jacko

fitted engine

mark chandler - 25/1/09 at 10:41 AM

My efforts in the same vien.

I used Range rover Polybush panhard rod bushes

Rescued attachment Engine_mounts_small.JPG

mark chandler - 25/1/09 at 10:42 AM

the bushes

Rescued attachment panhard_bush.jpeg

lsdweb - 25/1/09 at 10:53 AM

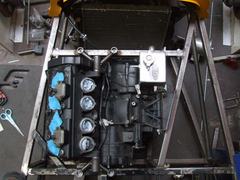

Here's my R1 inmy wide Westfield - no cradle as such - trying to keep the weight down. There are small brackets between the engine and the

chassis rail at the rear and the removable 'bar' at the front.

Rescued attachment SNV30525.JPG

a4gom - 25/1/09 at 02:21 PM

my idea was similar to that of lsdweb, a bar across the front of the engine to pick up the original front top right mount, a bracket direct to the

bulk head for the original front top left mount, s mount similar to lsdwebs top back mount and something in the same vain as mark chandlers top mount

for my bottom back mount.

The bushes I proposed would be inside 1" tube welded to the brackets.

Hope that makes sense.

I'm not over worried about strengthening the chassis, it worked ok with my old engine in and that was on two standard rubber mounts. I'm not

saying it wouldn't make it better but if I manage to get my driving and everything else on the car up to the the standard of the currecnt chassis

I can always add some stiffness!

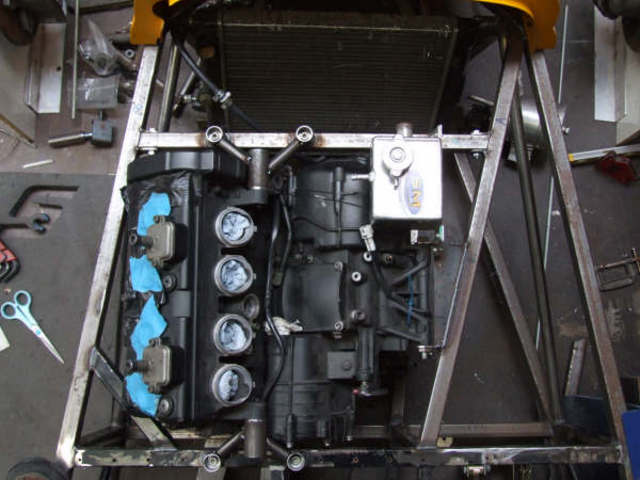

lsdweb - 9/2/09 at 08:02 PM

And here with all mounts completed.

Rescued attachment header tank install.JPG

lsdweb - 18/2/09 at 08:57 PM

And the bottom mounts

Rescued attachment mounts1.jpg

lsdweb - 18/2/09 at 09:00 PM

And here

Rescued attachment mounts2.jpg

Peteff - 18/2/09 at 11:22 PM

For the sake of a few more ounces I'd join the bottom mounts both sides together with another bar between them to make it a bit more rigid.

lsdweb - 20/2/09 at 01:05 PM

Thanks Pete

We did consider this - I'm tempted to leave it as is for now and see if there's any flex in there when it's running.

Ta

Wyn

Blackbird - 22/2/09 at 07:09 AM

Nice work.

And just to contribute another one for future searching, I'll post mine too -

I threaded the ones on the transmission and put bolts directly into it.

[img]http://www.jeepolog.com/forums/attachment.php?attachmentid=13959&d=1234510307[/img]

[img]http://www.jeepolog.com/forums/attachment.php?attachmentid=13958&d=1234510307[/img]

[img]http://www.jeepolog.com/forums/attachment.php?attachmentid=13957&d=1234510307[/img]

Moti

Rescued attachment IMG_5095w.jpg