rose joint bush welding

Evrim - 26/6/08 at 06:33 PM

Hi there,

Am i a little bit anxious????

let me share my fear with you.If we make welding to the rear lower wishbone rose joint bushes with wishbone tube like pic1

the whole load act by wheel will be applied only the edge(protruding part)of the bush.If the edge part will crack we may lose the lower

wishbone!!!.That's why i make double-V-groove preparation and 4 cavity like Pic2 to laying the penetration to the base of the bush.

Any comments?

Rescued attachment P1000074.JPG

Evrim - 26/6/08 at 06:35 PM

Pic2

Rescued attachment P1000059.JPG

RichardK - 26/6/08 at 06:36 PM

Couple of holes further down the tube and plug weld as well?

Thats what I did

Rich

[Edited on 26/6/08 by RichardK]

Evrim - 26/6/08 at 06:40 PM

good idea

Evrim - 26/6/08 at 06:41 PM

before welding

Rescued attachment P1000061.JPG

Evrim - 26/6/08 at 06:43 PM

after welding.How about my welding?

Rescued attachment P1000063.JPG

worX - 26/6/08 at 06:48 PM

I'd happily drive a car that had that made for it. Although - I too would of welded a pool into the hole as suggested above.

All the best with the others!

Steve

jacko - 26/6/08 at 06:49 PM

looking good

RichardK - 26/6/08 at 06:50 PM

Looks fine to me though fella, if the paranoia is kicking in, as above stick a couple of holes in further down and plug it up.

Cheers

R

Evrim - 26/6/08 at 07:14 PM

I thing you are right, making holes is beter then what i did .Thank's to all

mark chandler - 26/6/08 at 09:02 PM

Nothing wrong with that, its correct practice to make a fishmouth and back fill.

The weld is then over a longer distance lessening the load on any specific point.

Regards Mark

Evrim - 1/7/08 at 04:22 PM

Hi mate,

I make two hole (8mm) and weld the bush as suggested.

Rescued attachment P1000084.JPG

Evrim - 1/7/08 at 04:37 PM

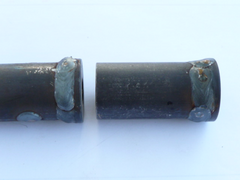

meanwhile I change the settings of the mig welder before welding the bush.Below you can see the bush welded with new settings on the left and the

previous one on the right.(I reduce the voltage and wire speed to obtain a stable result)Can anyone see the difference?is it still good

enough

Rescued attachment P1000085.JPG

Evrim - 1/7/08 at 04:38 PM

.

Rescued attachment P1000086.JPG