Tiger PU Bushes

DaveFJ - 4/4/05 at 11:59 AM

OK - not the usual debate!!!

Finally getting around to fitting my wishbones. started putting in the PU bushes yesterday and (apart from them being really easy top fit!) I have

found that they seem to be too big ?

Unfortuantely i did not take a picture but basically when the bushes are put in from each side and touching in the middle there is about a 1mm gap

from the edge of the tube to the shoulder of the bush (2mm total)

It would sem to me that this would allow the wishbones to move sligthly backward and forward?

Is this correct ?

my other simpler question is where do the tiger supplied metal bushes fit ? I'm guessing outboard end of lower rear wishbones but I can't

find that confirmed anywhere ?

Cheers

Andrew Bause - 4/4/05 at 12:20 PM

Hi Dave,

You will have to cut down the bushes slightly as the bush shoulder need to be flush with the wishbone tube for them to fit the brackets on the

chassis.

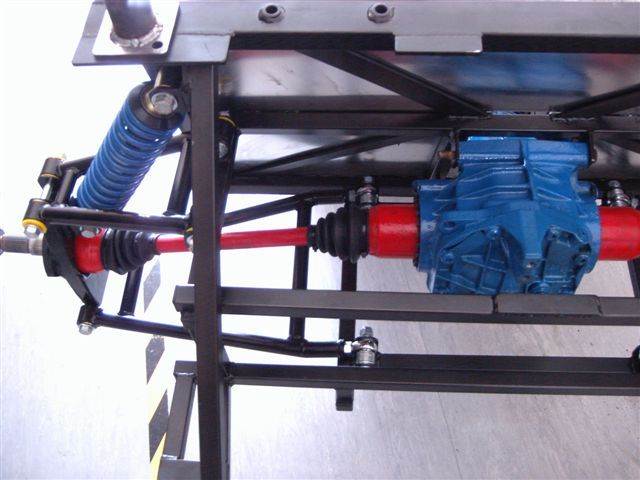

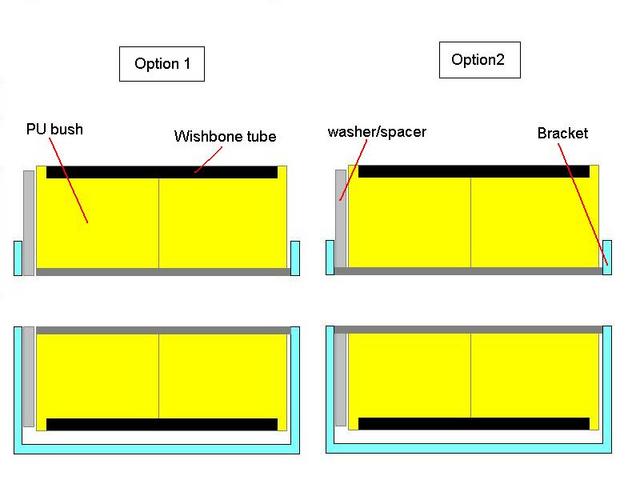

Metal bushes should be fitted in the lower outboard joint of the rear susspension, attached pic shows.

Cheers!

Andy Bause

VX 16v AVON

Rescued attachment tiger2 001.jpg

DaveFJ - 4/4/05 at 12:47 PM

Cheers, guess i will now have to remove a couple of bushes  which will no doubt be more difficult than fitting them

which will no doubt be more difficult than fitting them

In your picture it would appear that the rear wishbones are the other way round than explained in the book (bad english). The book says that the

longer arm should be to the rear...

Is that just an optical illusion or is it another "feature" of the book to be wary of ?

Cheers

DaveFJ - 4/4/05 at 01:41 PM

Any suggestions on the best way to cut the bushes down ?

cheers

carlgeldard - 4/4/05 at 02:22 PM

The book is wrong. Fit the lower rear wishbones opposite way to what it says in the book. Well thats if you are looking at revison one of book.

DaveFJ - 4/4/05 at 03:51 PM

cheers... yet another - tigerism....

andrew.carwithen - 4/4/05 at 04:03 PM

quote:

Originally posted by carlgeldard

The book is wrong. Fit the lower rear wishbones opposite way to what it says in the book. Well thats if you are looking at revison one of book.

WTF??!!

Please, Carl, please tell me you're mistaken!!!

As I've mentioned elsewhere, I've got a v.early chassis and I bought it part - built c/w original edition of the 'book'.

My rear wishbones are as per the book, i.e. longer arms of 'bones (both upper and lower) are at rear.

( I must admit, that the shockers are twisted within their brackets - but I put this down to yet another example of 'iffy' Tiger quality

standards and the rubber bushes.)

So, your saying that the revised edition of the book states that they should be fitted the opposite way round?!! - Is that both the upper and

lower 'bones or just the lower?

I need to get this right, 'cos it means I'm gonna have to strip the rear end down (yet again!!)

If anyone's got the revised edition, can they please double check this for me, before I embark on swapping them around. I'd really

appreciate it.

Many thanks,

Andy.

DaveFJ - 4/4/05 at 04:08 PM

and so another can of worms is opened.......

Hellfire - 4/4/05 at 04:13 PM

I read this section of LB often - it's reassuring!

andrew.carwithen - 4/4/05 at 04:20 PM

quote:

Originally posted by DaveFJ

and so another can of worms is opened.......

...You started it!!!

Andy.

carlgeldard - 4/4/05 at 04:36 PM

Andy

About 2 years ago at Coiln King's (Avon builder near York) Graham,Pat,Coiln and I were talking about things tiger related (as you do) and it was

agreed by all four of us that the book was wrong. Colin also said "Jim said the book is wrong flip the wishbone over" I know for a fact that

Tiger now put a small bead of weld on the wishbone to indicate which way around they go,But I can not tell you if its the weld bead to the front or

rear.

Carl

carlgeldard - 4/4/05 at 04:39 PM

Sorry forgot to say I don't know what it say's in the second book but chances are they only changed the picture on the front cover and the

price. (locost revision of the book)

Carl

andrew.carwithen - 4/4/05 at 05:08 PM

Carl,

I've just had a look at Colin King's build manual (downloaded from N.E.T.O.C site).

He states that the 'weld' on the lower bones goes to the rear.

Do yours have this weld marking and, if so, what arm is it on (longer or shorter?)

There's a revised edition book on ebay at mo'. I'll see if I can put in a successful bid, (finishes tomorrow) and if so, I'll be

able to tell all, what exactly, the differences are between the two editions (so, please, will nobody else on here bid on it! )

)

Andy.

Northy - 4/4/05 at 05:10 PM

I spoke to Tiger directly about this (after the above night), and they said, "No fit them as the book." After discussing this with them for

a while, they said they would go and put one together to try. They then said, " Your right, fit them oposite to what the book (1st edition)

says."

The most important thing is the measurement from the back of the chassis to the end of the wishbone it mentions in the book, is it 110mm from

memory?

Sorry

Northy - 4/4/05 at 05:11 PM

quote:

Originally posted by Hellfire

I read this section of LB often - it's reassuring!

I little bird told me your not having such a simple time on your rebuild though

andrew.carwithen - 4/4/05 at 05:18 PM

Graham,

Did you flip over both upper and lower wishbones or just the lower?

Andy.

Northy - 4/4/05 at 05:19 PM

Just lower

andrew.carwithen - 4/4/05 at 05:29 PM

So, to recap:-

Upper wishbone - long arm to rear.

Lower wishbone - long arm to front.

Correct?

Thanks,

Andy.

P.S.

(I'll probably ask the same question on the main Tiger forum - There's far too much space taken up with technical queries on the Cat and Six

anyway! )

)

carlgeldard - 4/4/05 at 05:33 PM

I made my own wishbones so I don't have the welds in question.

Hellfire:-You would love the engineering challenge and you are only jealous because you got an MK

Carl

carlgeldard - 4/4/05 at 05:36 PM

Andy

It was disscussed on the old Yahoo site do a search

Carl

andrew.carwithen - 4/4/05 at 06:38 PM

quote:

Originally posted by carlgeldard

Andy

It was disscussed on the old Yahoo site do a search

Carl

Found it!

( still listed in 'my favourites' Surprised I was still able to search old messages:cool

Yep, flip over bottom 'bones only.

Not out of the woods yet, though.....

Carl, I know you haven't swapped your uprights from one side to another ( I seem to remember you saying on another post somewhere  that your

callipers are at the front?)

that your

callipers are at the front?)

But, Graham and I have so that callipers are at rear.

So, Graham, if you read this, did the bones and uprights still line up ok inspite of this? (thought there was some sort of offset in the uprights as

well?)

Thanks,

Andy.

Northy - 4/4/05 at 06:47 PM

quote:

Originally posted by andrew.carwithen

So, Graham, if you read this, did the bones and uprights still line up ok inspite of this? (thought there was some sort of offset in the uprights as

well?)

Thanks,

Andy.

Yes, no offset in the upright

andrew.carwithen - 4/4/05 at 07:20 PM

Yes, no offset in the upright

Good! Oh well, looks like I'll be swapping the rear end around again then!

While I'm at it, Is it advisable to replace the rubber type bushes for Poly? - are they that superior? (I'd imagine it'd be a bitch of

a job to remove the rubber ones?)

Should I get them from Tiger or are there better alternatives out there?

Finally, As Davef asked in his last post, what is the best way of cutting down the poly bushes to fit?

(I do apologise, Dave, I did somewhat hijack your post!  )

)

Cheers,

Andy.

Lightning - 4/4/05 at 08:46 PM

Buggered if I'm changing mine . I spent ages aligning the rear wheels for camber and toe.

Andrew Bause - 4/4/05 at 09:51 PM

Dave, I'm assuming you have a late kit as you have Poly bushes? The rear lower wishbones have a short line of weld to indicate the side facing

the rear of the car.

Cheers!

Andy Bause

VX 16v AVON

[Edited on 4/4/05 by Andrew Bause]

Avoneer - 4/4/05 at 09:52 PM

Yeah, and we all know what fun Graham had fitting his rear bones!

And the rear shockers are meant to be on a stupid angle - tiger design!

Pat...

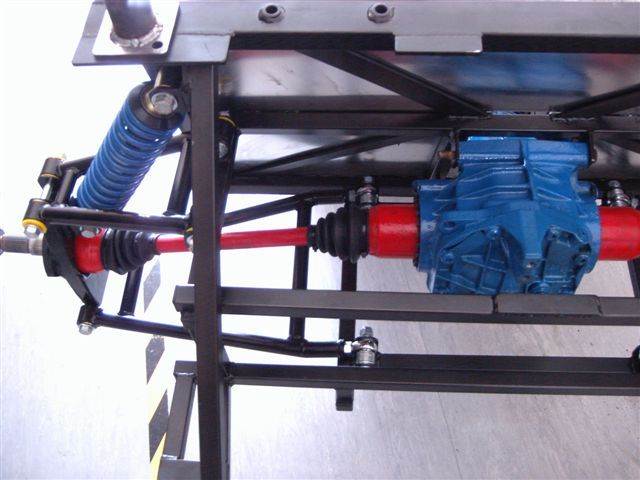

carlgeldard - 5/4/05 at 06:59 AM

Just to add more fuel to the fire before I get banned from the site. In the photo (Andrew Bause) it show's the rose joints on the bottom wishbone

at the front of the brakets mine are at the rear. And I think the uprights are offset. And don't ask which way around I have the uprights I just

can't remember. What I do remember is that chester sports cars did there rear setup like me see photo.

Carl

[Edited on 5/4/05 by carlgeldard]

Rescued attachment Rear Wheel.JPG

Northy - 5/4/05 at 07:07 AM

You were at that AutoSport show too then Carl

carlgeldard - 5/4/05 at 07:27 AM

Yes and No I got that photo off a Cd from Pat and he got the cd from you so that must be your photo just like this one

Rescued attachment Rear end.JPG

carlgeldard - 5/4/05 at 07:28 AM

and this one

Rescued attachment Graham.JPG

carlgeldard - 5/4/05 at 07:30 AM

And this one. Have you got anymore special interests. I know why there are no ladys at the Yorkshire meeting if your around.

[Edited on 5/4/05 by carlgeldard]

Rescued attachment Graham 2.JPG

DaveFJ - 5/4/05 at 07:56 AM

Sorry to bring us crashing back down on topic ...!

but I now have some piccies of my PU bushes as they are at the moment. According to the Tiger book the tubes on the wishbones should be 32mm - it

turns out mine are all 29mm Please could someone measure theirs and let me know the results (would be good to get a few answers for comparison)

anyway have a look at these pics and you will see what i my dilema clearly

(apologies to those on dialup)

Description

Description

Description

Description

Description

Description

Description

Description

carlgeldard - 5/4/05 at 08:30 AM

Mine are all 32mm but I made my own bones they also had an I/D of 26.5mm

Carl

Mix - 5/4/05 at 08:30 AM

Two options spring to mind,

1. Turn down the bushes and crush tubes to fit the bush tubes. Requires access to a lathe but will have the benefit of allowing small amount of

'room for adjustment' by shimming the wishbones within the mounts.

2. Turn some spacers from material identical to the bush tubes. Again requiring access to a lathe but less machining time required.

Mick

carlgeldard - 5/4/05 at 09:05 AM

I would think it's Tiger's problem if you got the bushes and bones from them.

If everbody tell you how long there tubes are and it is documented in the book as been 32mm. What can they do but offer you an exchange. It cannot be

a new design because they have not changed to brackets on the chassis or bushes.

Carl

DaveFJ - 5/4/05 at 09:13 AM

I have emailed Tiger about this, now waiting for a reply....

DaveFJ - 5/4/05 at 10:02 AM

Just been talking to Richard at Tiger in London;

apparently the bushes do need to be cut down a bit to fit

He also confirmed that the weld marked on the rear lower wishbone goes to the rear.

He suggested using a grinder or belt sander to shorten the bushes - any thoughts on this - I have been considering buying one of these:

which would seem ideal for the process - any thoughts ?

[Edited on 5/4/05 by DaveFJ]

carlgeldard - 5/4/05 at 10:13 AM

If you grind down the bushes won't you then have to pack out the brackets on the chassis to take out the slack. This can not be right. At least

you will be able to adjust the castor angle using washers.

Carl

DaveFJ - 5/4/05 at 10:18 AM

quote:

Originally posted by carlgeldard

If you grind down the bushes won't you then have to pack out the brackets on the chassis to take out the slack. This can not be right. At least

you will be able to adjust the castor angle using washers.

Carl

my thoughts exactly

Mix - 5/4/05 at 12:01 PM

Reducing the PU bushes won't be too much of a problem but I wouldn't attempt to reduce the lengths of the crush tubes with either a grinder

or linisher. IMO these need to be reduced on a lathe to maintain a square face.

Mick

shades - 5/4/05 at 05:17 PM

How do they look when the bolts are torqued up? Mine are the same, but I was hoping for the excess yellow to be taken up when tightened....

Northy - 5/4/05 at 05:19 PM

Cut the poly bushes down with a sharp knife, thats easy.

Why don't you get some washers with an ID of the OD of the crush tubes and use those? Saves shortening the crush tubes.

I shortened both BTW.

Cheers

DaveFJ - 5/4/05 at 09:53 PM

any piccy's of how yours turned out northy ?

also how did you cut down the tube ?

cheers

Northy - 5/4/05 at 09:58 PM

Might have some pics somewhere. Cut my crush tubes with a file!

DaveFJ - 7/4/05 at 04:07 PM

not sure how i am going to proceed yet with my poly bushes, but here is the next question just to get things going again....

how the f*** do you get the steel bushes into the lower rear wishbones? they are way to big!- I have tried heating the w/b and left the bush in the

freezer overnightand yet I still cant even get close to fitting. insides of tubes are nice and clear - (quick blast with a flap wheel) but the tubes

are just cutting into the lip at the end of the bushes. I have yet to try putting a schamfer on the tubes but with this much interference it seems a

bit hopeless

Northy - 7/4/05 at 05:08 PM

I didn't, I used poly bushes there.

shades - 7/4/05 at 06:09 PM

I used a long bolt from a hub puller, some washers and a big socket to pull the bush into the wish bones. Oh and a long brittool wrench... all 4

fitted in about half an hour. Still not sure what to do with the polly ones after reading the previous posts?

DaveFJ - 7/4/05 at 08:34 PM

OK,

fully cleaned up the tube and chamferd the leading edge. used a 10mm 8.8 ton bolt as the main puller. I got the bush in all the way but the last 8mm

by which time it was so stiff that I sheared the bolt!

bugger knows what i can try now.....

Northy - 7/4/05 at 08:43 PM

Use a stronger bolt?

carlgeldard - 8/4/05 at 07:12 AM

The bushes in question are tapered not that you can see with the naked eye. Have you got a vernier gauge. Also try going to a local garage Eg:- Main

dealers they will have a hydraulic press.

Carl

timwest167 - 8/4/05 at 09:16 AM

Broke two vices getting half of one bush in

£5 at a local garage with a manual press!

DaveFJ - 8/4/05 at 09:22 AM

quote:

Originally posted by timwest167

Broke two vices getting half of one bush in

£5 at a local garage with a manual press!

That makes me feel a little less 'alone'...

Will have to find a local garage that can sort it for me. cheers for all the help.

Fishface - 8/4/05 at 01:17 PM

I too broke two vices doing this and still paid 25 quid at the garage for them to do it. Also had to buy my dad a new vice. Hadnt costed for that.

What torque wrench settings have people used for the bolts on the suspension?

timf - 8/4/05 at 01:48 PM

quote:

Originally posted by DaveFJ

[Will have to find a local garage that can sort it for me. cheers for all the help.

dave,

want to borrow by 6 ton press

Tim

DaveFJ - 8/4/05 at 01:50 PM

I can feel a visit across town coming on......

Lightning - 8/4/05 at 05:04 PM

Used a pucker press at engine shop. Did it myself and gave the guy a drink. Took about 5 mins for all of the bushes. Tools for the job and all that.

andrew.carwithen - 9/4/05 at 08:25 PM

Just been looking at Chester Sportscars site.

They advertise poly bush sets for Tigers which they say are exclusive to them!

Does this mean they are different to the Tiger supplied ones (i.e actually fit?)

Has anyone fitted the Chester ones?

Andy.

carlgeldard - 9/4/05 at 10:03 PM

Mine are from Chester sportcars and they supply Tiger. It's down to Tiger to make all the wishbones the same.

Carl

Rescued attachment bush.jpg

Northy - 9/4/05 at 11:12 PM

I got mine from Chester Sportscars before they supplied tiger, and they fit the dimensions in the book. Pity the wishbones aren't the same as the

book

DaveFJ - 10/4/05 at 06:50 PM

Thanks to TimF my metal bushes are now fitted

Cheers mate

DaveFJ - 11/4/05 at 02:41 PM

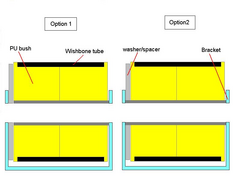

Ok so I now have 2 options to sort out my PU bush problem....

Look close the difference is subtle....

Bush options

Opinions please ...............

clbarclay - 11/4/05 at 02:51 PM

I would go with option 1. With option 2 you have a lose washer, that will cause wear to crush tube, braket, etc.

carlgeldard - 11/4/05 at 04:52 PM

Option 1

Reason as above

Carl

Northy - 11/4/05 at 07:11 PM

I did option 1

Lightning - 11/4/05 at 08:34 PM

Option 1, you will need all the adjustment you can to get the castor angle the same both sides.

which will no doubt be more difficult than fitting them

which will no doubt be more difficult than fitting them

)

)