side panel - interior trim interface

FASTdan - 15/1/09 at 03:18 PM

the PO of our indy has re-made the side panels in aluminium - well i think they are re-made, are they alu as standard? Well, he either re-worked the

originals or made new.

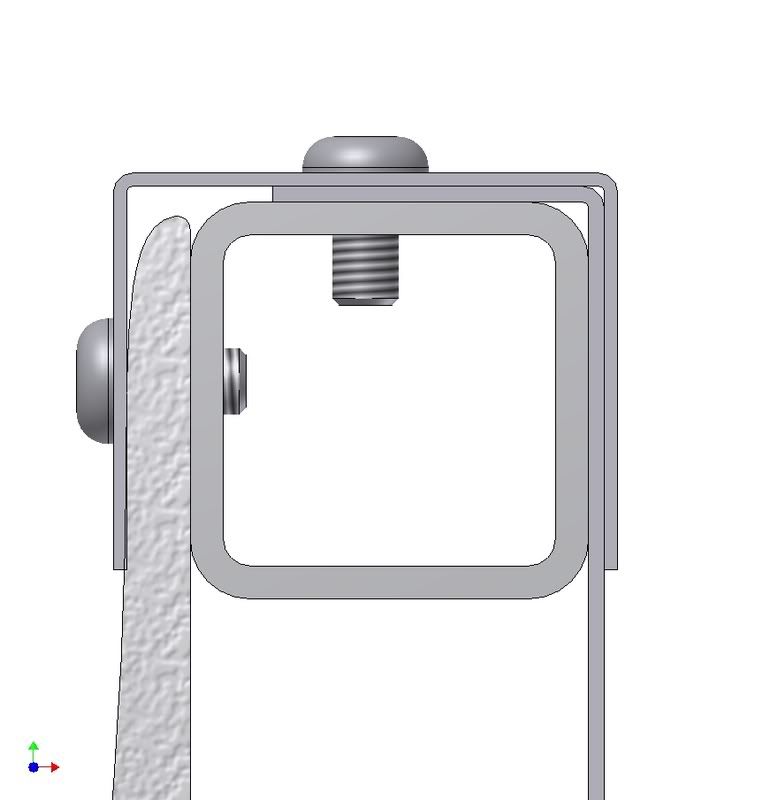

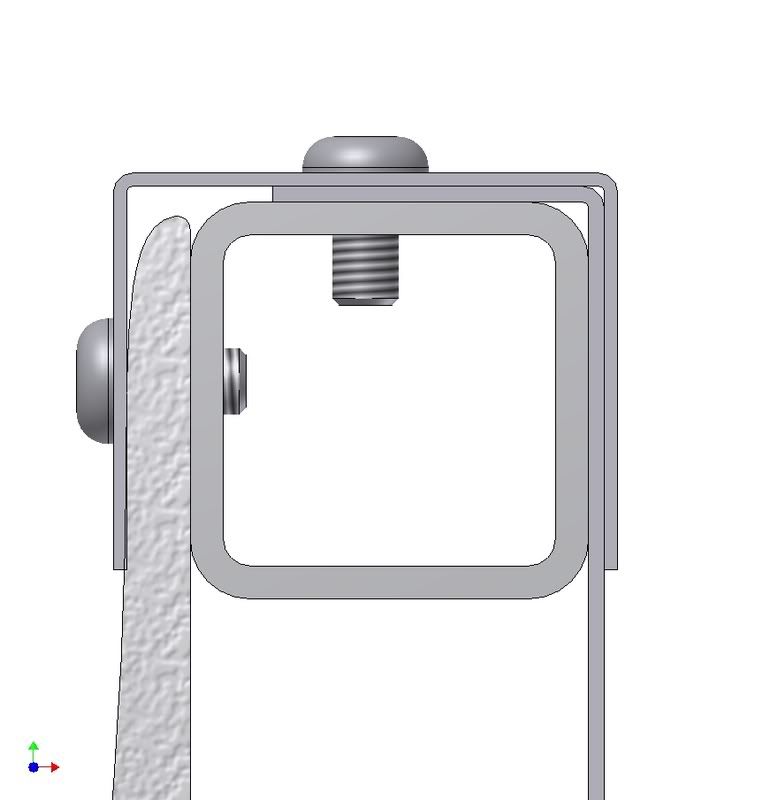

On the top of the 'door' area, the panel is folded over across the top of the box section but not right the way across. on the inside of the

car is an MDF trim card covered in vinyl. his intention was to make an alu channel as below to sit over the whole lot, clamping it all together and

'finishing' it off. however i am concerned that by doign this, the edge on the outside of the car (on the vertical face) will be an SVA fail

as it may be considered sharp (using say 1mm alu sheet).

Am i right in thinking that?

Its the same situation with the curved box running over the front of the rear arch. he intended on doing the same, and forming the alu around a curved

wooden former (that he gave me) - heating it using soap to indicate temperature. im not quite sure how this would work as i dont see where the excess

material would go in the two channel flanges? i'd expect it to just ripple.

what else can you do in this area?

Mr Whippy - 15/1/09 at 03:41 PM

fold up some vinyl and wrap it over the edge for the SVA

JeffHs - 15/1/09 at 03:56 PM

In my opinion/experience it won't be a problem

I had a similar worry with infill pieces above my small rear arches. They were 1mm ali plates riveted on to the face of the body skin. SVA tester said

was no problem at all. In fact he joked that you could use razor blades and still pass because they are thinner than the 1.5mm requirement for a

'blunted edge'

adithorp - 15/1/09 at 08:49 PM

As its only 1mm then it doesn't have to be radiused; Just "blunted". So if he runs his hand along it and it bleeds, then its not

"blunted".

Just run a file lightly along the edge to take off the corner and it'll be fine.

adrian