speedyxjs

|

| posted on 6/3/08 at 08:01 AM |

|

|

Square tube bending

Iv got loads of square tube left after building the front of my chassis and i want to use some of what is left for the curved sections on the back.

Is there a locost way to bend square pipe without takiong it to a pipe benders?

I have some spare wheels at home, could i use a blowtorch to heat up the metal and just bend it round the wheel?

How long can i resist the temptation to drop a V8 in?

|

|

|

|

|

locoboy

|

| posted on 6/3/08 at 08:21 AM |

|

|

Someone posted a picture of somethign they used.

It was a bit of wood with a hole in it and it was clamped in a vice IIRC.........

It did the job,

ATB

Locoboy

|

|

|

colt_mivec

|

| posted on 6/3/08 at 08:31 AM |

|

|

I was experimented with this on saturday in our rolls.

Tube aint keen on been bent as it starts to crease and flare. Im trying to fine some of them plastic bungs for 25x25box so i can fill it with sand on

a small section and try again.

Ill post some pics this weekend of the difference sand makes

|

|

|

iank

|

| posted on 6/3/08 at 09:09 AM |

|

|

quote:

Originally posted by locoboy

Someone posted a picture of somethign they used.

It was a bit of wood with a hole in it and it was clamped in a vice IIRC.........

It did the job,

John Bonnett is the man with the bending beam.

More info in these threads

http://www.locostbuilders.co.uk/viewthread.php?tid=48785

http://www.locostbuilders.co.uk/viewthread.php?tid=76028

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

Bluemoon

|

| posted on 6/3/08 at 10:21 AM |

|

|

I would be tempted to try the bending beam, Did something similar on the windscreen wiper Bundy tube worked a treat, all the other methods ended up

crushing the tube to much.. I just use a pipe flaring clamp for the bending beam as the bundy tube was small.. If your handy with a chisel and have

some hardwood you should be able to bend the square section..

Dan

[Edited on 6/3/08 by Bluemoon]

|

|

|

DaveFJ

|

| posted on 6/3/08 at 10:29 AM |

|

|

I saw someone (can't remeber who sorry) that had cut Vee's in the tube and bent it that way, then welded up the cuts..... By the time he

had ground down the welds you couldn't tell!

Dave

"In Support of Help the Heroes" - Always

|

|

|

Dick Bear

|

| posted on 6/3/08 at 10:53 AM |

|

|

I think the question was about SQUARE tube not round. If I'm not mistaken the timber method works only with round tube.

I have a square tube bender I made from three metal wheels I turned and mounted them in a triangular arrangement. The center wheel has both a divet

forming center in addition to side supports. As the tube is fed into the "machine" the center wheel divets the inside wall of the tube

while the side supports on the wheel hold the tube vertically creating a curved square tube. Multiple passes are necessary to accomplish greater

degrees of bending.

The wheels are driven by an electric motor turning a bicycle chain over sprockets at all three wheels.

The process works on thin wall aluminum as well but you are limited to a lesser degree of curve than is possible with mild steel due to the brittle

nature of extruded aluminum tube.

Dick Bear

www.marketpointproductions.com

|

|

|

speedyxjs

|

| posted on 6/3/08 at 11:19 AM |

|

|

Dick Bear - Yes you are right its square tube. Could you possibly send me some pics of your creation?

How long can i resist the temptation to drop a V8 in?

|

|

|

iank

|

| posted on 6/3/08 at 11:38 AM |

|

|

The bending beam will work on square, Mr Bonnett will be along soon I'm sure to confirm or deny but here is a picture from one of the threads I

linked to.

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

Dick Bear

|

| posted on 6/3/08 at 08:12 PM |

|

|

Great! If the timber method also works on square tube then go for it. Drilling a hole in a 2 x 4 sure beats building a machine to do the same

thing!

I just thought that as a square the side walls would collapse without any place for the extra material to go. Perhaps it has something to do with the

amount of bend you are planning to do.

Dick Bear

www.marketpointproductions.com

|

|

|

907

|

| posted on 6/3/08 at 11:12 PM |

|

|

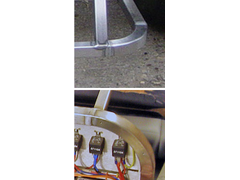

I gave up trying to bend it. I found it easier to fabricate them.

I needed 8 bends. 4 for the chassis rear end and 4 for the scuttle frame.

I cut from sheet, rings & strips and welded them to form 2 box section rings.

Cleaned up the welds and cut each ring into 4. (i.e. 90deg bends)

See pic

Paul G

Rescued attachment cassis-bends-s.jpg

|

|

|

Fred W B

|

| posted on 7/3/08 at 06:11 AM |

|

|

Damn nice work Paul

Often (in a non production enviroment) doing things "right" turns out easier than a shortcut method.

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Bluemoon

|

| posted on 7/3/08 at 08:45 AM |

|

|

Hi Fred, there's not a wright or wrong way to do it, 907 ways is great specially in Stainless steel.. The bending beam might not work for

Stainless but should in mild steel, if you use hard wood..

Dan

|

|

|

907

|

| posted on 7/3/08 at 04:43 PM |

|

|

Absolutely, Fred & Dan.

I think it depends on what equipment you have at hand.

If you have a plasma, lathe, or in my case a nibbler with a circle cutter attachment, then the rings are a doddle.

If not, then use what method you can.

There is always more than one way to achieve the same end.

Cheers

Paul G

|

|

|

TheGecko

|

| posted on 8/3/08 at 12:41 AM |

|

|

I bent a series of square tubes to make up my structural ring frame scuttle. I had access to one of these:

which is made locally (linky to MetalCraft) although I'm sure there are equivalents around the

world.

Here's the end result which next will be plated in thin sheet (with nice, swaged lightening holes):

Dominic

|

|

|