ProjectX

|

posted on 14/3/07 at 09:38 PM posted on 14/3/07 at 09:38 PM |

|

|

Engine mounting rails, ideas please

Hello guys, Just a quick one. Im sure I have seen something posted before but....

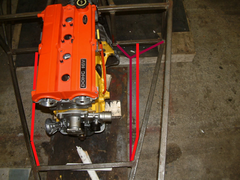

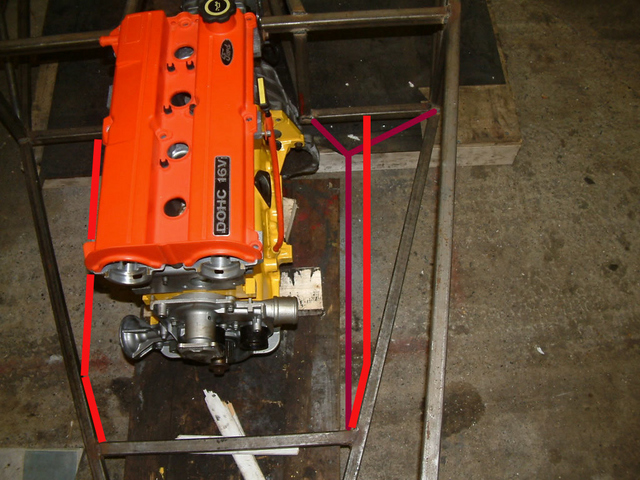

Trial fitting engine tonight  (good feeling too) but wanna know this. (good feeling too) but wanna know this.

Drivers side (O/S) straight mounting rail as here!

N/S is this any good?

Triangulated to miss starter etc. Any better ideas?

Cheers Jamie

|

|

|

|

|

blakep82

|

| posted on 14/3/07 at 09:52 PM |

|

|

isn't there supposed to be rails where you drew the lines anyway?

EDIT: oh, i see what you mean now, you're putting one in, and wondering about the other side...

I don't know, doesn't seem as strong to me with the triangulation there.

not an ideal solution, but could the engine be raised to clear the rail?

[Edited on 14/3/07 by blakep82]

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

caber

|

| posted on 14/3/07 at 10:44 PM |

|

|

The Pinto I have was heavy enough to flex these rails. Some people have doubled them up I chose to add a brace from the rear upper suspension mount to

the engine mount plate thus reinforcing both the suspension mount that needs additional support and the engine mount plate. I also added tube under

the engine mount plate between the two rails to reduce any twist across the plate even though it is 5mm steel!

Belt and braces maybe but I didn't want the engine continuously flexing these bits of chassis with consequent potential for problems!

Caber

|

|

|

MikeRJ

|

| posted on 14/3/07 at 10:59 PM |

|

|

quote:

Originally posted by ProjectX

N/S is this any good?

It is good in the sense that it's about the best way to maintain the triangulation of the engine bay whilst creating more clearance, but it does

mean you have a welded joint in the middle of a tube that is being put under fairly high bending forces. It will probably be fine, but as caber says,

mounting the engine directly onto these rails isn't ideal anyway and they do tend to flex a fair bit. Adding extra triangulation as he suggests

is a good idea IMO.

|

|

|

Chippy

|

| posted on 14/3/07 at 11:49 PM |

|

|

I added flitch plates to mine, plus a brace from the top rail down to the engine mounting. Think there are one or two pictures in my archive that show

them. HTH Ray

To make a car go faster, just add lightness. Colin Chapman - OR - fit a bigger engine. Chippy

|

|

|

Peteff

|

| posted on 15/3/07 at 12:11 AM |

|

|

I doubled up on the bottom rail at the front then ran the engine support rail from further back to get more width and I made the front of the tunnel

wider as well.

Rescued attachment enginemountpositionsn_s.jpg

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Guinness

|

| posted on 15/3/07 at 09:38 AM |

|

|

I'm no expert (mine has a loverly light bike engine), but if I was going to mount a car engine I'd do it like this:-

mikes suggestion

HTH

Mike

|

|

|

ProjectX

|

| posted on 15/3/07 at 08:51 PM |

|

|

Thanks for all these ideas! Not sure what ill do yet but at least i have a sensible idea! Beer to all

Cheers J

|

|

|