oneandoneis2

|

| posted on 1/11/06 at 11:00 AM |

|

|

Round vs. rectangular

I live in a second-storey flat, so I'm regrettably not in a position to build a Locost until I move home, hopefully in a year or two. So

I'm using the time to try & learn as much as I can before I start building.

So, first question: The book, and all the Locost builds I've come across so far, make the chassis out of RHS. But I was under the impression

that round tubes were better for spaceframes.

Is RHS used just because it's easier, or are there other important reasons too?

|

|

|

|

|

02GF74

|

| posted on 1/11/06 at 11:07 AM |

|

|

quote:

Originally posted by oneandoneis2

Is RHS used just because it's easier, or are there other important reasons too?

yes, to join 2 sections at an angle requires 2 straight cuts, with tube you need to "fishmouth" them - there is a program that will print

the template onto a peice of paper that you wrap round the tube and cut or you can spend £££ on the special tool..

Also flat sides make it easier to rivet on flat panels.

|

|

|

Hammerhead

|

| posted on 1/11/06 at 11:12 AM |

|

|

Follow this link

http://gtslocost.locostsites.co.uk/downloads.htm

And thank Flak Monkey for the info.

And welcome.

|

|

|

smart51

|

| posted on 1/11/06 at 11:15 AM |

|

|

Round tubes are lighter / stronger (or a bit of both) than square tubes. Square tubes are easier to cut and easier to weld. The choice is down to

whether you want it easier to make or better to drive. It may be better to complete a RHS frame than fail to complete a round tube frame

MNR recently dropped their RHS chassis in favour of all round tube after buying a tube bending machine. It allows them fewer cuts and fewer welds per

chassis. They also have a fishmouth grinder too.

|

|

|

cloudy

|

| posted on 1/11/06 at 11:21 AM |

|

|

hole saw + pillar drill = cheap tube notcher. It's really not much harder to make. tis a pain mounting things to tube though

James

|

|

|

Agriv8

|

| posted on 1/11/06 at 11:40 AM |

|

|

You also need to be more accurate when drilling / rivetting floor on.

As mm each way makes life very dificult.

regards

Agriv8

Taller than your average Guy !

Management is like a tree of monkeys. - Those at the top look down and see a tree full of smiling faces. BUT Those at the bottom look up and see a

tree full of a*seholes .............

|

|

|

oneandoneis2

|

| posted on 1/11/06 at 01:47 PM |

|

|

Thanks for all the replies. It's as I thought, then: Technically better, but practically much harder.

Given that I've never yet even touched a MIG welder, I think I'll go with RHS. For the first one, anyway

|

|

|

Alan B

|

| posted on 1/11/06 at 02:21 PM |

|

|

I'd disagree....I've built many of both types.....and say "practically, a little harder"....although when it comes to compound

angles round wins easy over square....

Also I'd recommend square tube rather than RHS...RHS wall thickness's are generally too thick

|

|

|

chockymonster

|

| posted on 1/11/06 at 02:22 PM |

|

|

quote:

Originally posted by Agriv8

You also need to be more accurate when drilling / rivetting floor on.

As mm each way makes life very dificult.

regards

Agriv8

Tell me about it.

Round tube is a bitch to drill too but it does look a hell of a lot better and is lighter for the same strength

PLEASE NOTE - Responses on Forum Threads may contain Sarcasm and may not be suitable for the hard of Thinking.

|

|

|

Alan B

|

| posted on 1/11/06 at 02:24 PM |

|

|

I try and avoid drilling tube if I can....when using round I'll usually weld tabs on for attachments.....

Extra work and a pain...yes...but it looks great IMO

A few tabs can be seen on this.....

[Edited on 1/11/06 by Alan B]

|

|

|

oneandoneis2

|

| posted on 1/11/06 at 02:44 PM |

|

|

Oooo, pretty

Maybe I'll just try out a few bits of both round & square tubing before I start building and see what I make of them both.

I'd prefer round, just so long as it won't cause any major problems. .

|

|

|

caber

|

| posted on 1/11/06 at 09:41 PM |

|

|

Wish i had thought more about this before I started. I thought square tube would be generally easier to do, In retrospect the compound angles are a

real pain and fishmouthing with a pillar drill and hole saw is a lot easier than it sounds.

I will deffinitely try round tube for the next build!

Caber

|

|

|

kb58

|

| posted on 2/11/06 at 04:43 AM |

|

|

quote:

Originally posted by caber

Wish i had thought more about this before I started. I thought square tube would be generally easier to do, In retrospect the compound angles are a

real pain and fishmouthing with a pillar drill and hole saw is a lot easier than it sounds.

I will deffinitely try round tube for the next build!

Caber

My findings exactly, round tubes everywhere - except where panels attach - then square is better.

Use both where they excel.

[Edited on 11/2/06 by kb58]

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

3GEComponents

|

| posted on 3/11/06 at 03:49 PM |

|

|

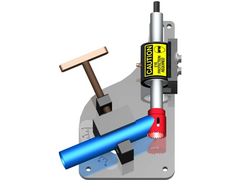

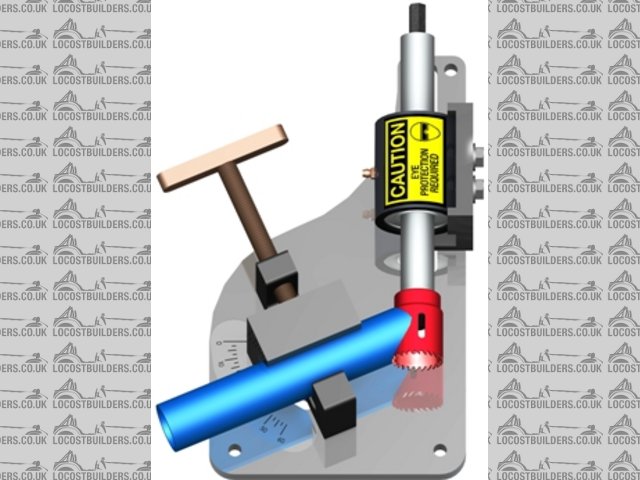

I purchased one of these from the States, only $199, about £100, not too dear for a tool. It does do fantastic joints and the cutters are cheap.

It's a HSN 500 notcher, from a company called protool or something like it.

Rescued attachment hsn500-full.jpeg

|

|

|

Alan B

|

| posted on 3/11/06 at 04:17 PM |

|

|

Yup...that's the one I have too....works very well.......Protool do some good stuff, I got my bender off them too.....

|

|

|

lexi

|

| posted on 6/11/06 at 05:20 PM |

|

|

I need convincing that 25mm round is stronger than square in the same gauge............especially where torsional rigidity is concerned.

Alex

|

|

|

02GF74

|

| posted on 7/11/06 at 03:14 PM |

|

|

quote:

Originally posted by lexi

I need convincing that 25mm round is stronger than square in the same gauge............especially where torsional rigidity is concerned.

I don't it will be, but then the 25 mm square will weigh more. So the get same strenht as 25 mm square the roud tube would be a bit bigger say

27 mm but still lighter than 27 mm sauqre - if that makes sense.

|

|

|

flak monkey

|

| posted on 7/11/06 at 05:22 PM |

|

|

Search for old posts.

I posted a load of maths about 7 or 8 months back with all the comparisons in, and have done on occasions before this too. I cant be arsed to do the

maths again!

David

Sera

http://www.motosera.com

|

|

|

jlparsons

|

| posted on 15/1/07 at 12:27 AM |

|

|

From what my old man said, the best rule of thumb is take any given tube, dip it in fairy liquid and blow a half bubble out the end. The steepness of

the wall of the bubble is proportional to the addition that part of the tube wall adds to the stiffness of the member.

Or something like that. Bloody engineers.

I do remember the bit I was supposed to take away though - round's stiffer torsionally than square or rectangular tube.

Any resemblance to real persons, living or dead is purely coincidental. Some assembly required. Batteries not included. Contents may settle during

shipment. Use only as directed. No other warranty expressed or implied. Do not use while operating a motor vehicle or heavy equipment. Subject to

approval, terms and conditions apply. Apply only to affected area. For recreational use only. All models over 18 years of age. No user-serviceable

parts inside. Subject to change. As seen on TV. One size fits all. May contain nuts. Slippery when wet. For office use only. Edited for television.

Keep cool; process promptly.

|

|

|