Gremlin

|

| posted on 15/5/03 at 09:47 PM |

|

|

Corner Brackets

When i welded the underside of the chassis i ran the grinder along the joins before welding so that when i ground them flat to put the floor on i

would hopefully have more weld left and a stronger joins.

Even though i have done this i would like to make sure the chassis will not bend or snap and wondered if i could add strength by adding corner

brackets like the triangle seat belt brackets shown in the book but between rails H + m H + l H +D1 H +D2?

Other than the extra weight is there any reason i cant do this and will this give me extra strength?

EZy GreMLiN

"The only way to get rid of temptation is too give in to it..!"

|

|

|

|

|

stephen_gusterson

|

| posted on 15/5/03 at 11:02 PM |

|

|

do you mean like this....?

It seemed a good idea to me cos

1. those point have important joins - especially the lower front bars.

2. good for jacking points.

atb

steve

Rescued attachment 111.jpg

|

|

|

Gremlin

|

| posted on 15/5/03 at 11:19 PM |

|

|

Not exactly although thats a good idea and if you dont mind may adopt it myself.

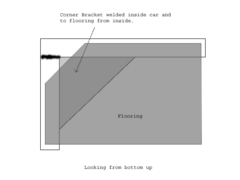

I was thinking vertically between H +D1 etc like the seat belt brackets for the lap belt.

Sorry another quick and dodgy diagram.

Just really wanting to know if this will help strength and if so if there is any reason i cant add as many of these as i feel i need because its an

issue with passing the SVA or something silly.

Rescued attachment Corner Bracket.gif

EZy GreMLiN

"The only way to get rid of temptation is too give in to it..!"

|

|

|

Gremlin

|

| posted on 16/5/03 at 12:00 AM |

|

|

Or

Another idea after seeing yours stephen.

Could you weld into the corners of A1 + B1 etc a triangel of 3mm plate flush to the bottom of A1 etc so the flooring will lay flat on it. Then cut the

corner of the flooring out so the welds on the underside of the chassis dont need to be ground down plus extra strength of corner bracket.

Similar to yours but on the inside and leaving original chassis welds un touched.

I realise it will be raised inside the car by 3mm but by the time carpet or seats go in you wont see the plates.

Any thoughts?

Im very bad at explaining so here is another bad diagram to try and help.

It seems to be a diagram day.

Sorry to keep asking crap questions but thanks in advance for any comments.

Rescued attachment Corner Bracket 2.gif

EZy GreMLiN

"The only way to get rid of temptation is too give in to it..!"

|

|

|

stephen_gusterson

|

| posted on 16/5/03 at 12:03 AM |

|

|

i was too lazy to look em up last time!

more bracing = more strength, byt those points dont look especially weak.....and the plates I suggest would kinda do the same job - being under the

car in approx same place.

In tube position TR3 I used inch RHS and did an X shape......

TR1 was also replace by RHS in an X shape, but is a bit tricky where they cross.

atb

steve

|

|

|

stephen_gusterson

|

| posted on 16/5/03 at 12:07 AM |

|

|

you posted between my answers!

my floor was welded first, without any cyt aways.

However, as the rhs is an inch wide, around 10mm was left at the side of the floor to the edge of the car.

So, I welded my extra plates on top of the floor and along the edge of the plate shuch that it was welded to the rhs past the floor but to the edge of

the car......the piccy might show....its less hassle than splicing in corners.

Its probably all not needed, but I thought it would help my heavier car and amateur welding!

atb

steve

|

|

|

Gremlin

|

| posted on 16/5/03 at 12:14 AM |

|

|

Ok thanks for the help.

So anything is better than nothing although probably not needed at all.

I will have to see, not sure what i will do yet but expect i will do something for no other reason than piece of mind. Like yourself am a amateur with

the big sparkler and just want to be sure.

At the end of the day if it aint right now its going to be a pain the arse to fix when engine, gearbox, floor and seats etc etc are in.

[Edited on 16/5/03 by Gremlin]

[Edited on 16/5/03 by Gremlin]

EZy GreMLiN

"The only way to get rid of temptation is too give in to it..!"

|

|

|

Spyderman

|

posted on 16/5/03 at 10:26 AM posted on 16/5/03 at 10:26 AM |

|

|

Gremlin,

As long as your welds are getting good penetration there should be little or no concern with grinding the weld nearly flat in order to butt floor pan

onto tubes.

Your idea for the triangulation should work ok and will take a bit of the load out of the junction.

It is not really necessary as the the chassis should be strong enough, but if it makes you feel better then go for it.

I will be doing similar things on joints where extra loads might be carried like the scuttle etc.

Stevens use for jacking points is also a good idea and should avoid rippled floorpans.

Terry

Spyderman

|

|

|