Gav

|

| posted on 8/9/06 at 07:59 PM |

|

|

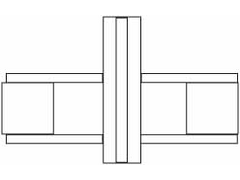

Rear harness fixings

I did the rear harnes fixings before i got my seats so made them a bit taller than i really needed, i can cho an inch or so of them if needs be, but

do you think These would fail SVA?

The bar actually goes through the 3mm plate and is fully welded both sides and the plate is fully welded to both tubes.

Ive seen an MK Chassis and they are quite tall but not this tall.

|

|

|

|

|

nitram38

|

| posted on 8/9/06 at 08:17 PM |

|

|

If you had an accident, your body can exert a load that could be 10 times your body weight onto these points. The longer they are, the more lateral

shear would be created and may rip them out.

Shorter is better, or better still, have more poking through underneath than on top.

[Edited on 8/9/2006 by nitram38]

|

|

|

Sacal

|

| posted on 8/9/06 at 09:22 PM |

|

|

Brrrrrrrrr

Always makes me shiver when people ask if belt mounting will pass SVA, shouldnt you be asking if they will save your life in a crash? Its up to you,

but i for one wouldnt get in a car with belt mountings like that.

Example G forces on driver in crash

|

|

|

DIY Si

|

| posted on 8/9/06 at 09:29 PM |

|

|

It would be better if the tubes extended down through another plate on the underside of the chassis rails. As said, remember these are the two bits of

metal holding you in in the event it all goes wrong.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

DIY Si

|

| posted on 8/9/06 at 09:38 PM |

|

|

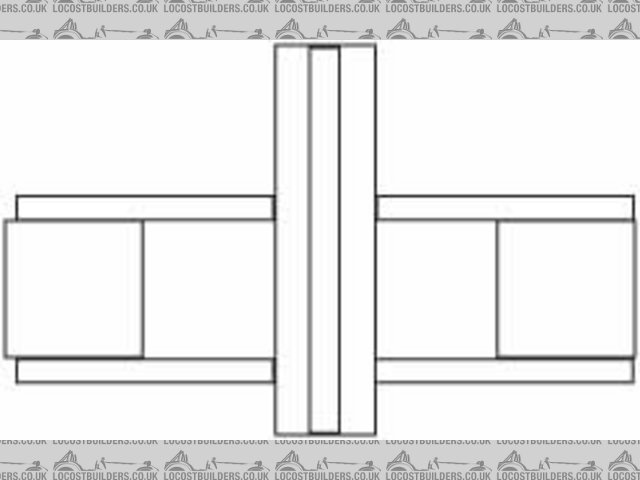

Like this, or something similar.

Rescued attachment harnessmount.jpg

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

Gav

|

| posted on 8/9/06 at 09:50 PM |

|

|

quote:

Originally posted by Sacal

shouldnt you be asking if they will save your life in a crash?

In a roundabout way thats what i am asking, The SVA is the bar which we all have to pass, if it passes the SVA then it is deemed safe is it not? and

as i said i made them taller than i needed so was planning to chop them down a bit, leverage a-side, i was more concerned with the method of welding

the bar through the plate and the plate fully welded to 2 tubes.

|

|

|

Gav

|

| posted on 8/9/06 at 10:18 PM |

|

|

Thinking about it, it would be quite difficult to remove the tubes and place longer tubes though and add a second plate, the tubes already protrude by

just under an inch under the plate but this isnt enough to add a second plate to the bottom tube, i think i may add a gusset plate at the front of the

tubes, may look ugly but hey ho

|

|

|

DIY Si

|

| posted on 8/9/06 at 10:27 PM |

|

|

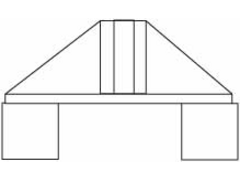

Like this you mean:

Rescued attachment harness2.jpg

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

Mark Allanson

|

| posted on 8/9/06 at 10:30 PM |

|

|

Deformation is the key to survival. As long as your welds hold strong, twisting of the mounting tube will actually add to the safety of the car. It

will be absorbing energy instead of transmitting it to your ribcage.

If SVA will see it that way, is upto the skill of the examiner

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

DIY Si

|

| posted on 8/9/06 at 10:35 PM |

|

|

But it will also allow you to move forward and thus slacken your harness. Or that's how I was told they'd see it. Depends what modd the

tester's in I suppose.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

nitram38

|

| posted on 9/9/06 at 03:09 AM |

|

|

Seat belt mounts are not designed to deform. In fact lots of inertia reel seatbelts have explosive tensioners to increase tension.

|

|

|

Mark Allanson

|

| posted on 9/9/06 at 07:34 PM |

|

|

The pretensioner is designed to pull the body back in the initial nanoseconds of the impact, and to work in collaboration with the airbag. If the

impact is sufficiently heavy, then the belt mounts are most certainly designed to deform, the reinforcement plates in most modern cars have pressed

corrugations to direct the forces in the required direction. This makes life a little more complicated for bodysops to repair, but if the belt mounts

have moved, the car is usually a total loss in any event.

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

dnmalc

|

| posted on 9/9/06 at 09:15 PM |

|

|

Being a chartered mechanical engingeer working in the defence industry I have data on that the time for the match head in the gas motors used for

pretensioners to fire and for the propellant to burn. this typically takes between 60 and 100 microseconds. However that only pressurises the system

which resists movement, it does not tighten the seat belt. For that to happen the inetia of the mounting the seat belt and that of the

driver/passenger have to be overcome before tightening starts to happen. As the inertia of the belt and the pasengers /drivers body are considerable

in reallity you are talking about tenths of seconds rather than nano seconds.

|

|

|

nitram38

|

| posted on 9/9/06 at 09:33 PM |

|

|

quote:

Originally posted by Mark Allanson

The pretensioner is designed to pull the body back in the initial nanoseconds of the impact, and to work in collaboration with the airbag. If the

impact is sufficiently heavy, then the belt mounts are most certainly designed to deform, the reinforcement plates in most modern cars have pressed

corrugations to direct the forces in the required direction. This makes life a little more complicated for bodysops to repair, but if the belt mounts

have moved, the car is usually a total loss in any event.

The corrugations in the inner sills are there to allow the monocoque to deform and absorb any energy. The seat belts have reinfored plates so that

they do not give.

The sva requires that bushes are welded both sides of box section or have reinforced plates on floor pans.

Evidence will be required if the welds are in accessible, usually photos will do.

The belts are designed to stretch/tear in order to absorb energy and not the chassis mounts.

|

|

|

Mark Allanson

|

| posted on 9/9/06 at 09:35 PM |

|

|

Whats a chartered mechanical engingeer - is that like ginger geer?

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

dnmalc

|

| posted on 10/9/06 at 07:54 PM |

|

|

mark

it like an accountant your tied to a desk and never get to play with the toys

|

|

|

Peteff

|

| posted on 10/9/06 at 08:42 PM |

|

|

you are talking about tenths of seconds rather than nanoseconds.

I don't think any mechanical system would react in time measurable in nanoseconds. It takes light over 3 nanoseconds to travel a metre, it

travels 11.8" in 1 nanosecond. If a nanosecond was a week a second would be approximately 1,602,564 years. I know it's not relevant to

seat belt mounts but it's something I was looking at the other day. I think if you gusset the mounts they would be o.k. but would be better if

they were mounted on a square of rhs, with two short pieces joining the two long pieces together to stop the plate from buckling or twisting.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|