sforma

|

| posted on 3/7/06 at 08:16 PM |

|

|

Cosmos, Ansys and Pro Eng. Element Analysis to the chassi?

Hello,

Before start to build the chassis some of you draw the model and do some changes in it using AutoCAD or similar software.

Using that type of software is relatively simple to do a simulation to see the “limits” of the chassis and in witch part of the chassis it will be

most dangerous.

Some names of that kind of software are Ansys, Cosmos-SoliWorks and Pro.

So, I would to know if anyone use this kind of software- Finite Element Analysis?

Best Regards

Tiago

|

|

|

|

|

MikeRJ

|

| posted on 3/7/06 at 09:08 PM |

|

|

Yes, there is a member on here called Cymtriks that has performed FEA on the Locost chassis.

The results of his work can be found at http://locost7.info/files/chassis/kitcaranalysis_V2.doc

|

|

|

sforma

|

| posted on 4/7/06 at 02:41 AM |

|

|

thanks for the info, i need to convert the units to the SI so i can understand all the results.

|

|

|

nitram38

|

| posted on 4/7/06 at 08:26 AM |

|

|

Don't know much about chassis software, but I do know that if you jack one wheel of my car up, 2 others lift up aswell.

I think my chassis is stiff enough for the job!!!!!

|

|

|

MikeRJ

|

| posted on 4/7/06 at 08:39 AM |

|

|

quote:

Originally posted by nitram38

Don't know much about chassis software, but I do know that if you jack one wheel of my car up, 2 others lift up aswell.

I think my chassis is stiff enough for the job!!!!!

Not a lot of suspension travel then?

|

|

|

JB

|

| posted on 4/7/06 at 03:02 PM |

|

|

Chassis Analysis

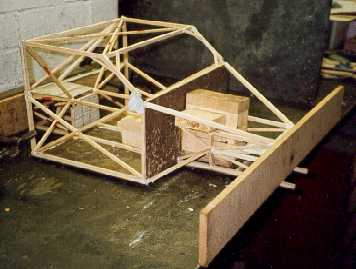

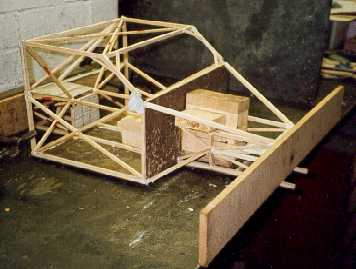

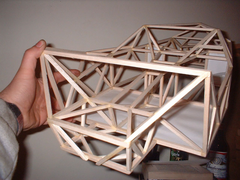

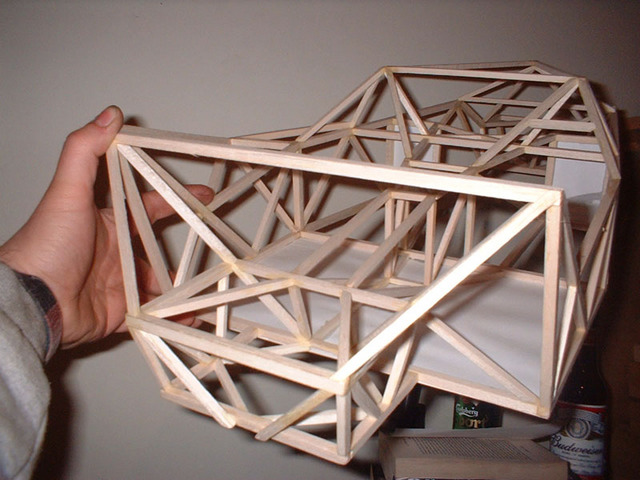

My advice is a wooden model. Use 6mm wood available from B&Q and a glue gun.

It is quick and will tell you so much so easily. Twist it and bend it in your hands. I seem to have so much trouble convincing people of this method,

but then when they try they are stunned just how much they learnt. The main comment is along the lines of "Blxxxy hxxxl my chassis was

crap"

Then possibly use a computer. i used Grape (I think) to get some figures on my cage.

John

|

|

|

John Bonnett

|

| posted on 4/7/06 at 04:35 PM |

|

|

Our bible when building our car back in the late 90s was Alan Staniforth's Race and Rally Car Source Book.

There is much useful information and some invaluable tips in there. Among these, is to start with a balsa wood model chassis. This scales very well

against a steel frame and you can easily check your design for stiffness and clashes with mechanical components etc.

A really good book which Ican throroughly recommend. ISBN 0-85429-572-0

|

|

|

leto

|

| posted on 4/7/06 at 04:36 PM |

|

|

quote:

Originally posted by JB

My advice is a wooden model. Use 6mm wood available from B&Q and a glue gun.

It is quick and will tell you so much so easily. Twist it and bend it in your hands. I seem to have so much trouble convincing people of this method,

but then when they try they are stunned just how much they learnt. The main comment is along the lines of "Blxxxy hxxxl my chassis was

crap"

Then possibly use a computer. i used Grape (I think) to get some figures on my cage.

John

Done something similar, but a scale model about 1:10 made from gas welding rods, mig welded together. It is a great way to understand how a chassis

work and where it may fail. And with some paint it also looks good in the bookshelf .

“I'm gonna ride around in style

I'm gonna drive everybody wild

'Cause I'll have the only one there is a round”. (J. Cash)

|

|

|

John Bonnett

|

| posted on 4/7/06 at 05:01 PM |

|

|

Staniforth uses balsawood for the model because the torsional stiffness of the model is directly scaleable to a fullsize steel spaceframe.

As an aside, Arthur Mallock who incidetally could not weld built his frame and then used a horizotal steel bar put through the frame and then twisted

to check for stiffness. The empirical method is always the best because there can be no inaccuracies or missed out factors.

John

|

|

|

iank

|

| posted on 4/7/06 at 05:56 PM |

|

|

I used balsa when I was playing around. Being able to grab the suspension mounts and twist taugth me than weeks of learning a s/w package ever would.

Use plastic card (from a model shop) to simulate welded in steel panels.

Got mine from hobbycraft, they do a bunch of sizes so you can scale build whatever you want (50x50, 25x25 etc) but any good model store should be able

to get some.

Oh yes, glue gun glue stays very hot for a while - found that out the hard way

|

|

|

MikeRJ

|

| posted on 4/7/06 at 06:11 PM |

|

|

quote:

Originally posted by iank

Oh yes, glue gun glue stays very hot for a while - found that out the hard way

Yep, it's also the 'stringiest' substance known to mankind, you pull the glue gun away from the joint and and you can walk to the

other end of the room before the string ends!

|

|

|

Liam

|

| posted on 4/7/06 at 06:48 PM |

|

|

Another vote for the balsa wood method here. Amazing how you can feel the difference that a single added tube or paper panel can make!

Liam

Rescued attachment chasismodel.jpg

|

|

|

cymtriks

|

| posted on 8/7/06 at 05:57 PM |

|

|

If you want to find out where the most highly stressed parts of the chassis are then I'd advise looking at making it stiffer first.

On nearly every analysis I've done a stiffer chassis has lower loads in most tubes for a given suspension load.

I can e-mail you a Nastran input deck if you want but it will be in imperial units.

|

|

|

kb58

|

| posted on 8/7/06 at 09:00 PM |

|

|

Good Lord Liam... that's nearly large enough to put the engine in and go - no steel needed!

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

britishtrident

|

| posted on 9/7/06 at 09:21 AM |

|

|

FEA isn't of any value unless you have enough engineering knowledge to know the correct type of elements and joints and exactly where to put the

restraints and loads.

Balsa model will tell a beginner far more.

[Edited on 9/7/06 by britishtrident]

|

|

|

britishtrident

|

| posted on 9/7/06 at 09:22 AM |

|

|

quote:

Originally posted by cymtriks

If you want to find out where the most highly stressed parts of the chassis are then I'd advise looking at making it stiffer first.

On nearly every analysis I've done a stiffer chassis has lower loads in most tubes for a given suspension load.

I can e-mail you a Nastran input deck if you want but it will be in imperial units.

Listen to this man he knows :-)

|

|

|