AdamR

|

| posted on 29/6/06 at 10:53 PM |

|

|

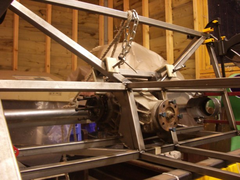

is my diff in the right place?

Yeah, I do know it goes at the back between the two round things...

I'm using GTS diff brackets and if I mount them in accordance with the GTS de-dion plans, the diff is too high up. With my trailing arms parallel

to the chassis, the centre of the diff output flanges are about 25mm higher than the centre of the de-dion hub carriers, so the driveshafts would

slope downwards to the hubs. I'm pretty sure they should be level (or even sloping upwards a little as they will be when the suspension is in

bump)?

Diff too high?

I have to hack the brackets around a little anyway as the face of the prop flange is about 5 degrees off vertical, so it'll be easy to move the

diff. But where should it be exactly, in relation to everything else?

[Edited on 29/6/06 by AdamR]

|

|

|

|

|

Avoneer

|

| posted on 30/6/06 at 12:04 AM |

|

|

Are the GTS brackets on the right way up?

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

ned

|

| posted on 30/6/06 at 06:16 AM |

|

|

looks to be in exactly the same location as mine Adam and mine is gts dedion and gts dif mounts.

will see if i can find a pic

http://www.locostbuilders.co.uk/upload/IMG_1006.jpg

http://www.locostbuilders.co.uk/upload/IMG_1004.jpg

[Edited on 30/6/06 by ned]

beware, I've got yellow skin

|

|

|

birdii

|

| posted on 30/6/06 at 06:40 AM |

|

|

I have welded my GTS brackets on but hadn't thought to check the angle of the drive shafts as I have only just fitted the de-dion, I have got

the same problem with the diff not being vertical, I put that down to possible errors in my chassis building but obviously its not.

I'll put the diff in place with the de-dion tonight and see how it looks. Won't the trailing arms be a little higher than horizontal at

normal running, I think horizontal would give off-roading ride height.

|

|

|

nludkin

|

| posted on 30/6/06 at 07:18 AM |

|

|

I have a W7DE chassis from gts, however I believe the position of the diff should be the same.

With the fully assembled back end the driveshafts point down very slightly (Probably about 5-10 degrees) and it measures about 5cm vertical between

the top of the bottom chassis tube and bottom of the de-dion rounded bit. (Damn I need pictures!)

The diff mount of my car though looks to be mounted lower though (As if 25mm has been cut off the bottom on mine?)

The bottom diff bolt is about 5-51/2 cm from the bottom of the chassis.

|

|

|

JoelP

|

| posted on 30/6/06 at 07:31 AM |

|

|

mine is about 6" from the bottom of the chassis to the centre of the flange. Coupled with a 4" rear ride height, the driveshafts should be

perfectly level, since the wheels i have are 10" radius including tyres.

You could lower it from there to keep the CoG down, and put up with the shafts aiming up to the wheel.

[Edited on 30/6/06 by JoelP]

|

|

|

iank

|

| posted on 30/6/06 at 09:33 AM |

|

|

quote:

Originally posted by AdamR

...

I have to hack the brackets around a little anyway as the face of the prop flange is about 5 degrees off vertical, so it'll be easy to move the

diff. ...

Before you hack your brackets around the flange doesn't need to be exactly vertical, anything up to 3 degrees ish will be no problem and might

be beneficial. It does need to be parallel with the gearbox output flange, so you might want to get everything in place before doing anything

permanent.

I presume GTS are using jigs to make the brackets etc. so it's hopefully like that for a reason. Might be worth calling to confirm.

See this thread for more:

http://www.locostbuilders.co.uk/viewthread.php?tid=38077

|

|

|

birdii

|

| posted on 30/6/06 at 09:48 AM |

|

|

Thats a good point! I had left mine for now and was waiting for the gearbox/engine to go in before i made adjustments. I see what you mean though, the

engine and gearbox may not be parallel either which might be the reason for the diff not being 90 degrees.

I think there is a pic in my archive to show how far off mine was.

Anyway, i'll be leaving it alone until the engine position is finalised.

[Edited on 30/6/06 by birdii]

|

|

|

AdamR

|

| posted on 30/6/06 at 03:53 PM |

|

|

quote:

Originally posted by iank

Before you hack your brackets around the flange doesn't need to be exactly vertical, anything up to 3 degrees ish will be no problem and might

be beneficial. It does need to be parallel with the gearbox output flange, so you might want to get everything in place before doing anything

permanent.

I presume GTS are using jigs to make the brackets etc. so it's hopefully like that for a reason. Might be worth calling to confirm.

See this thread for more:

http://www.locostbuilders.co.uk/viewthread.php?tid=38077

Agreed, but my engine/gearbox will be going in dead flat, so my diff needs to match as you say.

Regarding the GTS brackets being accurately made, I agree there too - which is why I was suddenly worried about the accuracy of my chassis! Some

frantic measurements confirmed everything is OK though.

|

|

|

AdamR

|

| posted on 30/6/06 at 03:57 PM |

|

|

quote:

Originally posted by birdii

I think there is a pic in my archive to show how far off mine was.

Looks about the same as mine - there's a pic in my archive too. The height looks the same too.

|

|

|