caber

|

| posted on 7/5/06 at 09:46 PM |

|

|

FU1 FU2 AAARGH!

Guess what I have been doing this weekend? I think I have it set about right however I am running out of space around the front end to put in

everyting I need! I just aquired an exhaust manifold for my Pinto, I think it is either a locost or made from the lolocost manifold kit. Unfortunately

it takes up almost all the space on the driver's side so all the plans for steering routes are a bit knackered!

The other problems are around the front box where I don't seem to have room for the Cymtrix stiffening. I also have a problem fitting the

diagonal bracing on the sides of the engine bay.

Any ideas how to get more space or how to brace up the side with the diagonal routes blocked?

TIA

Caber

|

|

|

|

|

James

|

| posted on 7/5/06 at 11:34 PM |

|

|

FU1/2,

Firstly, can I suggest you wait untill you have your wishbones and bushes and suspension brackets before you continue with FU1/2, that way

they're more likely to end up in the right place. Also If you build a jig as per my photo archive you're more like to end up with them

right.

You may have all these bits already... I had a quick look through your archive but couldn't find any evidence of wishbones.

The steering isn't worth worrying about too much, at the end of the day you can always add an extra CV joint to help get round any angles. See

Steve Gustersons website for this.

As for the braces/Cymtrics stiffening.... I'm a bit confused as to what your issue is. If you don't have any of them in place and you

ain't done FU1/2 what the hell is there left that could be in the way!!!

A couple of pics fo the problems would help!!

All the best,

James

------------------------------------------------------------------------------------------------------------

"The fight is won or lost far away from witnesses, behind the lines, in the gym and out there on the road, long before I dance under those lights."

- Muhammad Ali

|

|

|

caber

|

| posted on 8/5/06 at 08:54 AM |

|

|

James, I do have wishbones etc. and have used a jig a bit simpler than yours just an H frame. I have had to mount the coil overs to the underside of

the top tube and I have the steering rack in place as well so that is why things are a bit busy in that area.

I started out setting the bottom wishbones true with the chassis and used the frame to mount the upper bones and FU1&2 so although it

doesn't look absolutely identical side for side I am pretty happy that the bones are in the corect positions.

I took the rack out again and tried to find a location with minimal bump steer, it is an escort rack from Rally Design. It seemd to make no diference

where it was located in the area there is still visible bump steer so I put it back to the book location.

The triangulation is pretty difficult to get in around everything but I do ned to get some in somehow!

ARRGH!

Caber

|

|

|

Peteff

|

| posted on 8/5/06 at 09:23 AM |

|

|

So you are building the car round a manifold you've bought? Put everything where you want it then make the manifold fit, usually by taking it

out over the top rail. There are lots of cars running round without cymtrics mods so don't get hung up on them, the book chassis performs well

without them. The standard cast manifold with a twin downpipe is good for up to 150bhp motors so unless it's absolutely got to go on use that

till the car is running then sort yours out.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

caber

|

| posted on 8/5/06 at 05:19 PM |

|

|

Pete,

I have been trying to sort the manifold out for some time and really don't want to stick it out over the top of the chasis rails. If I have to

change chassis construction I need to do this now before I start putting panels on. The manifold I have seems to have the right pipe lengths and a

good 4 into 1 header however it takes up a lot of room to achieve this.

I have a trial fit of the engine and transmission in now to avoid problems later, I already know I need to lift the engine mounts about 12mm and I am

trying to keep it as low as possible to get a good bonnet line, this is why I am putting sidedraught carbs on it and therefore it makes sense to

change the exhaust at the same time.

Right now it is all a bit fiddly and is annoying me!

BTWanyone know how to bolt in triangulation so you can take it out to acces bits and remove things?

Caber

|

|

|

Hugh Paterson

|

| posted on 8/5/06 at 08:29 PM |

|

|

Kev I suppose now would not be a good time to mention my source of exhaust sections or a four into one exhaust manifold made to measure, this of

course is a once in a lifetime offer but will have a word with someone tomorrow for the sections required, he owes me a favour (40ft trailer hint

hint)

Shug.

|

|

|

caber

|

| posted on 8/5/06 at 09:27 PM |

|

|

Shug, I may well take you up on this I am having less and less faith in being able to make the manifold I have work. at this rate I will have ALL the

parts left over to build another locost!

Caber

|

|

|

907

|

| posted on 9/5/06 at 09:11 PM |

|

|

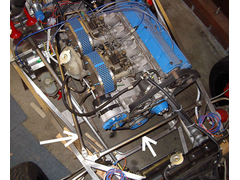

quote:

Originally posted by caber

BTWanyone know how to bolt in triangulation so you can take it out to acces bits and remove things?

Caber

Hi Caber,

My chassis is only a little bit booky, but since if the engine is removed its got to come forwards

I did a couple of bolt in jobbies, arrowed in the pic.

Paul G

Rescued attachment brace-003s.jpg

|

|

|

DIY Si

|

| posted on 9/5/06 at 09:26 PM |

|

|

Looks good that. What are the bolt in braces made of? cds with the ends flattened?

|

|

|

907

|

| posted on 9/5/06 at 11:26 PM |

|

|

almost.

316 with the ends flattened.

Paul G

|

|

|