Firefly

|

| posted on 5/1/03 at 07:58 PM |

|

|

Getting a flat surface!

Please could you help a frustrated newbie out?

I have tried using a piece of 1/2" MDF on the floor of my garage but notice that it still isnít flat with a slight curve of at one end.

How have others of you achieved a flat enough surface at the size necessary to start the chassis build?

|

|

|

|

|

interestedparty

|

| posted on 5/1/03 at 08:52 PM |

|

|

13 views and no-ones answered? this might solve your problem (it's not the way I do it, I built myself a sturdy 8'x4' table, and made sure it was

flat).

First of all, 1/2" is a bit thin, 3/4" would be better, anyway, lay it so that it curves up at the ends (Boards always curve one way, depending how

they've been stored, so turn it round if necessary) then screw it to the floor at maybe a dozen points around the edge. Between the board and the

floor use some slightly compressible material, stiff foam something like that. You can then get the board flat by tightening whichever screws more

than others, and checking with a decent spirit level. The board itself doesn't need to be perfectly level, but using the level will tell you if it's

bulging up because the level will rock

John

As some day it may happen that a victim must be found,

I've got a little list-- I've got a little list

Of society offenders who might well be underground,

And who never would be missed-- who never would be missed!

|

|

|

Mark Allanson

|

| posted on 5/1/03 at 10:15 PM |

|

|

This is the way I did it, 19mm MDF with 6x3 tree wood reinforcements going longwise and 1x2 RHS going sideways with legs welded on. Each leg has a M12

nut welded into the bottom and a M12 bolt wound in. Once set up you can adjust the bolts to give a level surface, I did have to shim with washers to

make exact. use a 25x25RHS run diagonally to check for perfect trueness

Rescued attachment DCP_0172.JPG

|

|

|

Jon Ison

|

| posted on 5/1/03 at 11:37 PM |

|

|

1" mdf ere............the chassis will move a little when you weld it up whatever you try............

|

|

|

Rorty

|

| posted on 6/1/03 at 12:48 AM |

|

|

I agree with Mr Allanson. Build something solid, and prefferably anchor it. Check for level in all directions.

If you go to the Tech Page on my site www.rorty.vze.com there's more detail about starting off.

If the construction is done well, there is no reason for the finished chassis to be more than 1mm out from end to end.

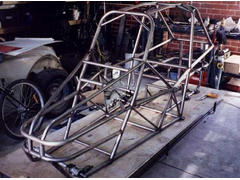

Rescued attachment R2chassis_on_stand.jpg

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

philgregson

|

| posted on 6/1/03 at 10:58 AM |

|

|

Built a framework of (straight) 3"x1" which is stood on tressles.

Over this I screwed 2 layers of (I know this is odd - but) 0.5" fire proof plasterboard that I happened to have after recovering them from a skip

(Going in the workshop roof when I have done).

It is dead flat, strong enough, fire proof for welding but very heavy - I'm not saying that this was the best way but it was the materials I had

in.

Phil

|

|

|