Slimy38

|

| posted on 22/8/18 at 07:16 AM |

|

|

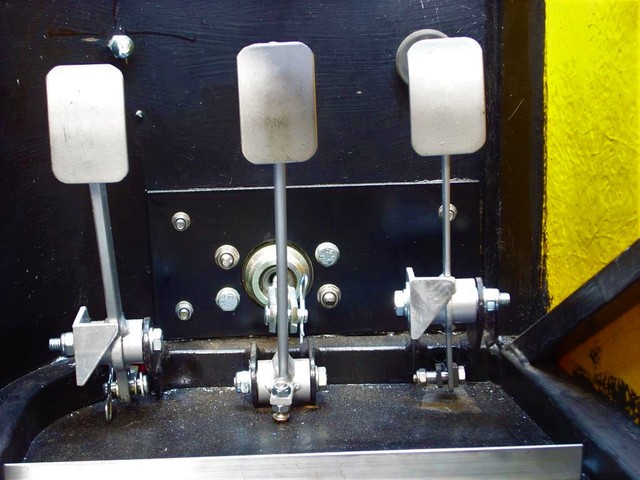

Brake pedal panel reinforcement

One of the things I read on the interweb talked about the drivers side footwell panel flexing under braking, and I have an opportunity at the moment

to reinforce it. However, I'd like to know if it's actually a thing to worry about or whether it is an uncommon occurrence.

I've used the recommended Haynes Roadster 3mm metal plate, split in two with the bottom half carrying the brake and clutch master cylinders (MX5

donor hence the hydraulic clutch). The lower half is bolted to the other half and to the chassis member at the bottom and seems fairly solid, but I

know the average braking force exerted by a human can be quite significant. Obviously even though the clutch is also hydraulic it won't be

adding to my troubles.

If anyone has reinforced this panel, do you have any photos showing what you've done and what benefits it's given? Or is it less of an

issue than people say?

|

|

|

|

|

mark chandler

|

| posted on 22/8/18 at 07:36 AM |

|

|

3mm is pretty hefty steel, much thicker than car manufacturers so I doubt you have a problem.

My bulkhead is 1/16" steel, I cut a spreader plate to reinforce where required, I doubt you have anything to worry about.

[Edited on 22/8/18 by mark chandler]

|

|

|

40inches

|

| posted on 22/8/18 at 08:17 AM |

|

|

Yep, 3mm is more than man enough. Mine is still solid after 4000 miles

Description

|

|

|

Slimy38

|

| posted on 22/8/18 at 08:33 AM |

|

|

Perfect, thanks for the confirmation. One less thing to worry about.

|

|

|

pewe

|

| posted on 22/8/18 at 11:23 AM |

|

|

If you do encounter flex (unlikely given your steel thickness) fabricate a brake master cylinder stopper.

I've knocked them up for the hairdressers and son's IntegraType R to good effect.

A google search will bring up several accessory ones but at £100+ it's taking the wee.

HTH.

Cheeers, Pewe10

|

|

|

Mr Whippy

|

| posted on 22/8/18 at 12:38 PM |

|

|

It may flex although I doubt it, but even then it's not going to rip out is it? Sounds like beefing it up would be just useless extra weight.

What's the thickness on a production car 0.8 - 2mm even in high load areas such as subframes and suspension mounts. If you still want to stiffen

it up do it properly with webs not plates

|

|

|

Slimy38

|

| posted on 22/8/18 at 01:05 PM |

|

|

quote:

Originally posted by pewe

If you do encounter flex (unlikely given your steel thickness) fabricate a brake master cylinder stopper.

I've knocked them up for the hairdressers and son's IntegraType R to good effect.

A google search will bring up several accessory ones but at £100+ it's taking the wee.

HTH.

Cheeers, Pewe10

Oh yes of course, I'd forgotten about those. I remember seeing them when I was looking at MX5's for a donor. I think I'll keep that

as my backup solution, thanks.

|

|

|

Angel Acevedo

|

| posted on 22/8/18 at 02:20 PM |

|

|

quote:

Originally posted by Slimy38

One of the things I read on the interweb talked about the drivers side footwell panel flexing under braking, and I have an opportunity at the moment

to reinforce it. However, I'd like to know if it's actually a thing to worry about or whether it is an uncommon occurrence.

I've used the recommended Haynes Roadster 3mm metal plate, split in two with the bottom half carrying the brake and clutch master cylinders (MX5

donor hence the hydraulic clutch). The lower half is bolted to the other half and to the chassis member at the bottom and seems fairly solid, but I

know the average braking force exerted by a human can be quite significant. Obviously even though the clutch is also hydraulic it won't be

adding to my troubles.

If anyone has reinforced this panel, do you have any photos showing what you've done and what benefits it's given? Or is it less of an

issue than people say?

I mounted my OBP Pedal box on top of two 25 X 25 mm X 3 mm Angle Iron welded to members D1 and the one across forming the bottom cornerof the

footwell.

For you in GB would be D2

Regards

AA

Beware of what you wish.. for it may come true....

|

|

|