andyharding

|

| posted on 31/8/04 at 09:12 AM |

|

|

Floor thickness?

How thick are people making their (steel) floors?

Please post in mm rather than gauge if possible.

Are you a Mac user or a retard?

|

|

|

|

|

nick205

|

| posted on 31/8/04 at 09:15 AM |

|

|

Mines 1.5mm thick Ally, PU bonded and rivetted every 1.5" to the chassis and it seems very solid.

HTH

Nick

|

|

|

Peteff

|

| posted on 31/8/04 at 09:29 AM |

|

|

16g is roughly 1.5mm and 18g 1.2mm. You shouldn't need anything thicker or thinner than this. You could go thinner if you can swage the sheet to

stop drumming and flex or put more support in but don't put tubes in where your feet need to go for the pedals or they could get in the way.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

James

|

| posted on 31/8/04 at 09:31 AM |

|

|

Mines about 0.8mm but swaged.

HTH,

James

|

|

|

stephen_gusterson

|

| posted on 31/8/04 at 09:50 AM |

|

|

1.6mm steel as I think it says in the book

However, I found that as you really need to add a couple extra cross bars to mount the seats on anyway, the floor could then be replaced with

something thinner, or softer, like alu. just b aware to put something decent where your feet stand on climbing in and out.

atb

steve

|

|

|

craig1410

|

| posted on 31/8/04 at 12:06 PM |

|

|

16swg (1.6mm) here too. With the minimal ground clearance I feel quite safe in the knowledge that I have a nice big chunk of steel between me and any

rocks which want to jump up and hit me between the legs...

It is also seam welded fully on the outer edge and stitch welded 1 in 6 on the inside edge.

Cheers,

Craig.

|

|

|

stephen_gusterson

|

| posted on 31/8/04 at 12:50 PM |

|

|

it was mentioned a few years back on the aussie yahoo list that someone in the outback on rought ground got speared by an object coming up through the

floor.....

atb

steve

|

|

|

Mark Allanson

|

| posted on 31/8/04 at 05:25 PM |

|

|

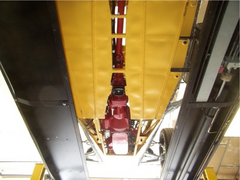

I did mine in 18g and braced with 13mm ERW, but look at the distortion

Rescued attachment Floor.jpg

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

stephen_gusterson

|

| posted on 31/8/04 at 06:04 PM |

|

|

im glad you posted that pic. When I welded mine up full seam at the edges, mine did just that too. Adding the seat braces stopped it pinging.

if a professional welder gets the same result, im well happy to have acheived the same!

atb

steve

|

|

|

MikeRJ

|

| posted on 31/8/04 at 09:17 PM |

|

|

Yep, mine did that as well. Not too worried though, you don't get to see the underside of the car very much (hopefully).

|

|

|

chrisf

|

| posted on 1/9/04 at 11:35 PM |

|

|

But if using ali...

What spec to use? 6061-T6?

Apologies for the hijack.

--Chris

|

|

|

Hugh Jarce

|

| posted on 2/9/04 at 04:57 AM |

|

|

6061 would be fine but may be costly and/or hard to locate. 5083 is fairly common and is a good structural grade. As is 5251...treadplate is made from

5251.

The pay isn't very good , but the work's hard.

|

|

|