lukeep

|

| posted on 26/4/11 at 03:53 PM |

|

|

Chassis design help

hello guys i posted on here a while ago. I am looking to see if someone preferabally local would be willing to mentor and help me and my mechcanic

friend design and build a chassis i understand box section or tubing as the chassis i need help mainly with suspention as double A frame style

1) how do design a double A frame front and rear suspention

2) Designing a light weight sturdy mid engine kv6 chassis

I know i am a novice but i really want to learn any help will be a bonus.

|

|

|

|

|

nick205

|

| posted on 26/4/11 at 03:58 PM |

|

|

Are you working on paper or in CAD?

Either way, you could post up your design ideas on here and receive the benefit of a much wider audience.

Might also be worth searching out some books on chassis and suspension design. Staniforth, Des Hammill, Haynes etc al cover aspects of deisgn and

build.

|

|

|

Kwik

|

| posted on 26/4/11 at 08:09 PM |

|

|

what will be the chassis use?

will it be a racer single seater, locost 7 type car, etc.

all the info, drawing, ideas, sketches on napkins, will all help

|

|

|

lukeep

|

| posted on 27/4/11 at 10:25 AM |

|

|

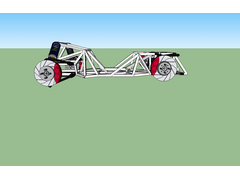

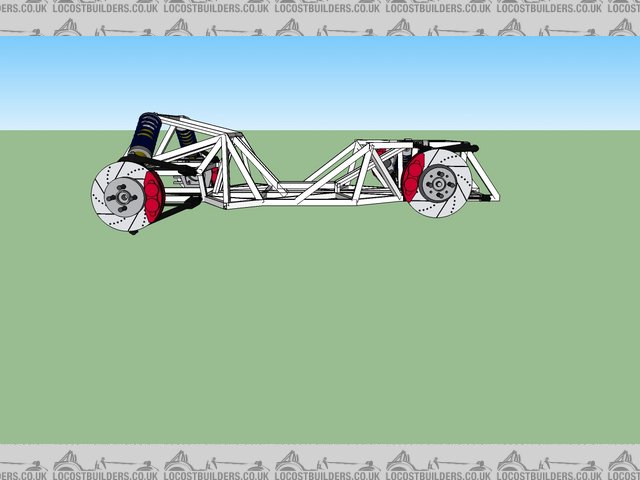

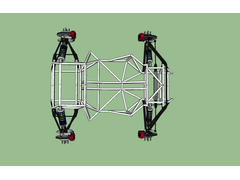

Hi guys I have added some quick mock ups of the main chassis using the abomination that is sketch up positive criticism gratefully accepted

|

|

|

Miks15

|

| posted on 27/4/11 at 10:38 AM |

|

|

mock up of entice chassis

mock up of en-tice chassis top

i think you need a bar across the big opening on the side view. Theres little to no strength in that area and as thats where you be sat i doubt youll

want it buckling around you!

|

|

|

designer

|

| posted on 27/4/11 at 10:45 AM |

|

|

Agree, it's going to bend.

Either needs some sills or a larger tunnel down the middle.

|

|

|

lukeep

|

| posted on 27/4/11 at 05:40 PM |

|

|

Cheers guys on the side view i cant re enforce there with a bar as the canopy like on the sterling nova will be there with a intergrated roll bar in

the canopy so what are my choices?

|

|

|

kb58

|

| posted on 28/4/11 at 02:41 AM |

|

|

Oh dear, yeah that'll bend in torsion really easily. The secret is to picture a tube; twisting a tube is really difficult, and you need

to replicate that somewhat. The easiest way is either a big central tunnel that's fully boxed in, outboard boxes below the doorways, or both.

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

Miks15

|

| posted on 28/4/11 at 07:47 AM |

|

|

So are you building this based on some other car? If so it would help if you posted a pic of the body you are trying to fit it to. Then well have a

better idea of your finished goal

|

|

|

lukeep

|

| posted on 28/4/11 at 07:28 PM |

|

|

its not baced on any other car i am just borrowing the concept that the car will have no doors the whole canopy will rise up and you will get out im

currentally mocking up some new models

|

|

|

Paul_C

|

| posted on 28/4/11 at 08:58 PM |

|

|

That's some impressive sketchup work.

If you want to calculate lateral, beam or torsional stiffness then I recommend LISA Finite Element Technologies at http://www.lisa-fet.com/

It's free for 1300 nodes which should be plenty for a spaceframe.

I used it on the spaceframe shown in Appendix 1 of Racing and Sports Car Chassis Design by Michael Costin and David Phipps.

The torsional stiffness came out as 1350 lbf ft required for 1° of twist.

All that is required is the x, y and z node co ordinates, the cross section of the members and the material Youngs modulus.

|

|

|

Miks15

|

| posted on 28/4/11 at 09:04 PM |

|

|

If you are copying the sterling concept then i reckon you can still have a higher beam across

Is this the one you mean?

I reckon a beam the same height as youre other rails and then have that as your top sill with the canopy sat on top should work

|

|

|

Badger_McLetcher

|

| posted on 29/4/11 at 03:51 PM |

|

|

If you can't put in sidebars then increase the size of the drive tunnel and make sure it's fully pannelled/triangulated. May not harbour

your drivetrain but you can still put stuff in there.

If disfunction is a function, then I must be some kind of genius.

|

|

|

blakep82

|

| posted on 29/4/11 at 04:03 PM |

|

|

its hard to draw it in on the drawing you've posted, but it looks real easy to add a bigger tunnel in.

really needs to be taller and a bit wider than you've got i think, but what you've got looks easily changed to suit

think beefing up the sides will be a lot harder

look at TVR chassis.

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

Mark Allanson

|

| posted on 29/4/11 at 04:17 PM |

|

|

quote:

Originally posted by Miks15

If you are copying the sterling concept then i reckon you can still have a higher beam across

Is this the one you mean?

I reckon a beam the same height as youre other rails and then have that as your top sill with the canopy sat on top should work

The Stirling was a copy of Richard Oakes Nova

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

tug

|

| posted on 29/4/11 at 04:24 PM |

|

|

Aren't those triangles a bit big? Remind me of buggies.

I don't want to be a dick, but from the pics you have provided it let me think that the car do NOT have the same wheel-to-wheel distance. And

they don't seem to be the same height.

Interesting design hope it works

|

|

|

coyoteboy

|

| posted on 29/4/11 at 06:15 PM |

|

|

Also zero triangulation in the rear box section. To be honest i'd be starting from scratch on that as there appears to be few redeeming features

- looks like it could be lighter, simpler and stiffer. Check out some race car chassis design books and on top of that decide how comfy you'd be

in it in an accident.

|

|

|

Kwik

|

| posted on 29/4/11 at 06:33 PM |

|

|

that design is good, but you need something connecting the front and rear like mentioned above.

the triangulation at the rear looks fine as long as it is a light weight car, look at the 7 chassis, loads of squares in them, you dont need to

triangulate everything and you dont need to "bird cage" everything (having lots of tiny triangles.

also you can used stressed skin instead of triangulation in parts so dont jump the gun and tell him he needs more triangulation... but you defiantly

need a transmission tunnel or something along the sides.

|

|

|

Liam

|

| posted on 29/4/11 at 09:15 PM |

|

|

Good starting point but that central section needs addressing seriously or it'll fold in half when you get in!

I appreciate it's just a mock up and not necessarily dimensionally accurate, but the proportions look rather odd - you've got pretty much

a square footprint! It's either abnormally wide or the cabin is abnormally short.

You need at least a full and triangulated transmission tunnel, and ideally also sides/sills of a decent height. You should be able to get at least

8" I would have thought and still be easily able to step in. Also, have some width in the side sills too, not just a single tube thickness -

build them like a box either side of the car.

Finally - rising canopy inspired by the Nova/Stirling? A bit... 80s sci-fi if you ask me!

Good luck

|

|

|

lukeep

|

| posted on 1/5/11 at 05:23 PM |

|

|

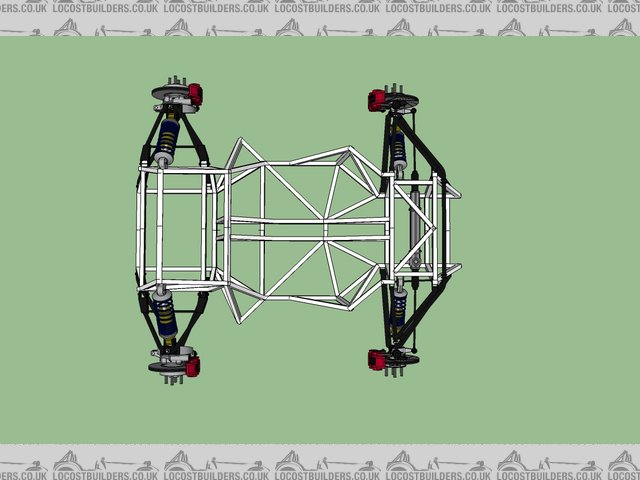

Hello guys I had some time this weekend so I took you’re advice onboard I have addressed the lack of triangulation and re enforcement well lack of as

well. again criticism gratefully accepted

Also En Tice Will look nothing like the sterling nova in any way shape or form.

REVISION FRONT

REVISION SIDE 2

REVISION SIDE 1

REVISION TOP

|

|

|

designer

|

| posted on 1/5/11 at 06:53 PM |

|

|

One of the cockpit side rails, from the shoulder area, meets another half way, without any support, which will introduce a bending motion.

|

|

|

Kwik

|

| posted on 1/5/11 at 07:16 PM |

|

|

and you wanna make a jig for that? so many odd angles...

your going to have a fiberglass body right? and im guessing interior paneling to cover the majority of the tubes. so why not keep it simple?

your design looks awesome, but in reality making a jig, cutting everything to the right angles and welding it neatly will be difficult, my advice

would be to keep it simple, especially if it is going to be covered up anyway...

|

|

|