Terrapin_racing

|

| posted on 19/3/04 at 12:35 PM |

|

|

Swaging Bulkhead/Panel holes

I'v had a storm of enquires as to how I neatly swaged the holes in the Terrapin bulkheads.

The solution is to make a press type tool (no press required) and use a 4 lb lump hammer to gently (seriously - no need to beat the panel to death)

tap the former until the hole has a perfect swage.

You could make the formers out of steel, brass etc. but having a passion for wood turning in a previous life I made mine out of lignum vitae

http://www.lignum-vitae.com/

I have made dozens of swages with no problems- indeed one tool is off on loan to a builder in Scotland shortly.

[Edited on 19/3/04 by Terrapin_racing]

Rescued attachment DSCF0028.JPG

|

|

|

|

|

Terrapin_racing

|

| posted on 19/3/04 at 12:37 PM |

|

|

The holes on the panels shown swaged on the rear anf front skinned bulkheads of my Terrapin MK1

Rescued attachment DSCF0023.JPG

|

|

|

Alan B

|

| posted on 19/3/04 at 01:00 PM |

|

|

Do the opposing swages meet each other?...and if so are they welded/brazed together?

|

|

|

Hugh Paterson

|

| posted on 19/3/04 at 01:17 PM |

|

|

Bloody hell, thats a neat job, I think the builder in Scotlands got hard job to match that beastie, hope yer looking at this Blake

Shug.

|

|

|

ceebmoj

|

| posted on 19/3/04 at 01:21 PM |

|

|

yes I have seen it and I will see how mine turn out but I have some douts as to wether thay will be as good as that.

blake

also that wood is very cool I had no idear that ther was any wood with oughs propertys.

|

|

|

Mix

|

| posted on 19/3/04 at 01:26 PM |

|

|

Lignum vitae is very scarce these days and consequntly expensive. One source are old grass bowls sometimes seem at boot sales.

I have used tufnol in the past to good effect and much more readily available.

Mick

|

|

|

ceebmoj

|

| posted on 19/3/04 at 01:33 PM |

|

|

Hi

I assume that is grows in the tropics and like a lot of hard woods is not farmed from a replenished crop. Does any one have a web sight with some more

details?

|

|

|

stephen_gusterson

|

| posted on 19/3/04 at 01:37 PM |

|

|

www.stjohnbeachguide.com/Lignum%20Vitae.htm

|

|

|

Terrapin_racing

|

| posted on 19/3/04 at 02:28 PM |

|

|

To answer a few questions -

the swages do not meet in the middle of the panels on the rear (as internal tubing is 3/4 square) so gap is about 3/8 to 1/2 inch.

On the front bulkhead which uses inner of 1/2 " OD tube the swages just about touch in a few areas but in all cases they are not brazed or

welded together at any points of contact - as per Lotus really.

Also get my LV from sustainable source (it's not cheap) last piece I bought which is 8inches diameter by about a foot high cost £30 - used about

£7.50's worht to make the large former in photo.

The smell when turning this stuff is fantastic!

cheers

Rob

[Edited on 19/3/04 by Terrapin_racing]

|

|

|

Terrapin_racing

|

| posted on 19/3/04 at 02:38 PM |

|

|

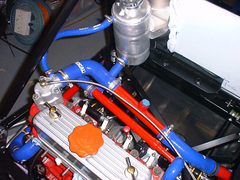

I like silicon too :-)

Rescued attachment eb3.JPG

|

|

|

drmike54

|

| posted on 25/3/04 at 05:47 PM |

|

|

swaged holes

Beautiful work. I recently started designing my chassis and have been reviewing books that I bought 30 years ago when I was in school. The Lotus 7 was

pretty state of the art then. The book I have has drawings of a Lotus F1 car from the space frame days with bulkheads like yours at each end.

|

|

|

Terrapin_racing

|

| posted on 26/3/04 at 09:29 AM |

|

|

Yes and still used in some areas today. In a lot of cases where these have been dispensed with in favour of straight forward box section tubing the

end weight has bee higher.

They look good too!

|

|

|