ned

|

| posted on 15/3/04 at 11:42 AM |

|

|

steel thickness for footwell bulkhead?

I purchased a lovely set of luego pedals at stafford and am wondering what thickness steel people weld into the drivers footwell to attach the pedals

to.

i have a hydraulic clutch, so three master cylinders all neatly in line. I'll need to drill holes for them and their respective fixings, so 1mm,

1.5mm, 2mm sheet? I have some 3mm but this is bloody heavy and will be overkill for this, but don't want to use stuff thats too thin as my brake

pedals will be attached to it!

Thanks,

Ned.

beware, I've got yellow skin

|

|

|

|

|

GO

|

| posted on 15/3/04 at 11:54 AM |

|

|

Ned, luego chassis has footwell fully welded in, and I think it'll be either 1mm or 1.5mm. I'm sure its not as thick as 2mm. I know,

I've had to drill through mine for hydraulic clutch!!

Dont think you need overkill on the footwell endplate, cos the pedal box itself is reasonably beefy.

HTH.

|

|

|

A Badger

|

| posted on 15/3/04 at 12:08 PM |

|

|

Ned,

I'm been looking at this for my mastercylinder, however it is a little different as I am am using the donor pedals and MC so it will be placed

higher up. Really it all comes down to stiffness rather than "strength". It's unlikely that you'll break anthing but you may

get flex which could be an issue in an emergency.

So you need enough thickness in the plate steel for the M/C's to fix firmly and not distort the fixings under load, I was then going to add some

bracing to make sure the whole thing can't flex.

When it comes down to it the pushrod's are not that thick I'm sure they would break first.

Andrew

|

|

|

timf

|

| posted on 15/3/04 at 12:09 PM |

|

|

wern't the sva testers failing mk's due to the fact the m/c area wasn't 'strong enough'

|

|

|

craig1410

|

| posted on 15/3/04 at 12:57 PM |

|

|

Hi,

I'm using top mounted pedals which attach to a steel plate of 4mm thickness above the top chassis rails. My footwell is fully welded 1.6mm

plate.

My m/cyls all attach to the 4mm plate and it feels nice and stiff. I don't think I'd have been happy with anything thinner than 3mm and

the 4mm give a bit of extra peace of mind and should avoid any unwanted attention from the SVA man...

Cheers,

Craig.

|

|

|

James

|

| posted on 15/3/04 at 01:01 PM |

|

|

Ned,

My footwell plates are 1.2/1.8mm IIRC. But then my footwell is a little smaller than standard.

With the column bracket welded on it stiffens it up nicely!

HTH,

James

|

|

|

ned

|

| posted on 15/3/04 at 01:01 PM |

|

|

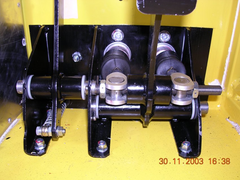

I will fully weld in whatever thickness i decide to use, to help the rigidity etc.

here is a pic of my nice new pedals:

luego_pedals

beware, I've got yellow skin

|

|

|

locoboy

|

| posted on 15/3/04 at 01:09 PM |

|

|

Ned,

Any chance you can measure the total length of the brake and clutch pedal and what thickness flat bar they are made out of?

Many thanks

ATB

Locoboy

|

|

|

PioneerX

|

| posted on 15/3/04 at 01:10 PM |

|

|

Ned,

Correct me if I'm wrong, and the picture seem to confirm this, but the master cylinders are not mounted to the bulkhead when using luego's

pedals there is a bracket fro them on the pedal box and therefore the pedal box is taking the strain not the buldhead.

Regards

Simon

|

|

|

Alan B

|

| posted on 15/3/04 at 01:13 PM |

|

|

Ned, they are a lot like my home made ones.

Mine is actually welded into the frame and I'll end up just skinning it with 16g Ali.

I was going to say use 3mm for sure, but I see the assembly itself is about that thick (like mine)...I would probably use 16g..

|

|

|

Alan B

|

| posted on 15/3/04 at 01:14 PM |

|

|

quote:

Originally posted by PioneerX

Ned,

Correct me if I'm wrong, and the picture seem to confirm this, but the master cylinders are not mounted to the bulkhead when using luego's

pedals there is a bracket fro them on the pedal box and therefore the pedal box is taking the strain not the buldhead.

Regards

Simon

Yep, kinda like what I was trying to say...   : :

|

|

|

ned

|

| posted on 15/3/04 at 01:17 PM |

|

|

i spoke to luego about mounting the pedals, cos i was on a bout getting them unpowdercoated. they said that the pedal box rests on the bottom bar and

then you bolt the master cylinder through the pedal box (obviously!) and then through the bulkhead panel to secure it, as opposed to welding it in

place. there are also holes on the bottom so it can be riveted or bolted to the floor.

Ned.

ps sorry colmacol! the material looks like 3mm plate to me, without measuring i recon the pedals are around 6-7" from pivot to top.

[Edited on 15/3/04 by ned]

beware, I've got yellow skin

|

|

|

wicket

|

| posted on 15/3/04 at 01:20 PM |

|

|

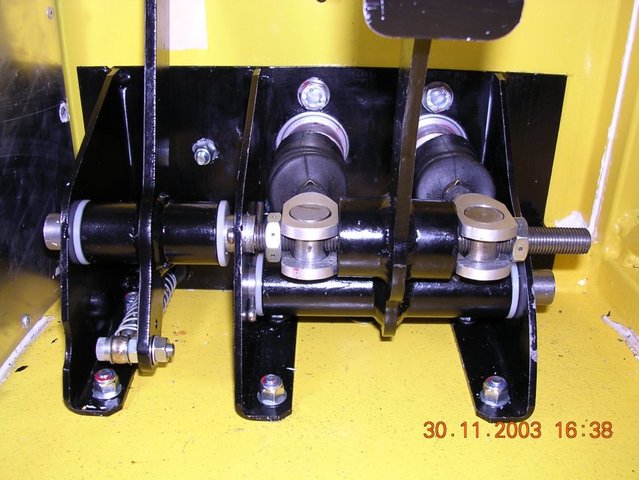

There are some pics in my archive of a Luego pedal box in place. The master cylinder mounting face of the box is against the bulhead panel.

[Edited on 15/3/04 by wicket]

|

|

|

ned

|

| posted on 15/3/04 at 01:26 PM |

|

|

thanks for the tip wicket, for those of you to lazy to look at wickets photo archive, hee is the same type pedal box in situ:

Pedal Box

Ned.

beware, I've got yellow skin

|

|

|

Terrapin_racing

|

| posted on 15/3/04 at 04:10 PM |

|

|

Snap!

Rescued attachment DSCF0003.JPG

|

|

|

britishtrident

|

| posted on 15/3/04 at 04:41 PM |

|

|

From what I can see from the picture most ot the load is carried in shear by floor, the vertical mounting only stopping the floor bending..

However --- on my own car which has pivoted pedals with the master cylinder mounted straight on to buckhead I used steel from and old Compaq

computer case -- about 1.8 mm I think AND bolted the cylinder on through stiffeners made from 18mmx 2 mm steel angles welded on inside the car.

|

|

|

wicket

|

| posted on 15/3/04 at 09:25 PM |

|

|

The vertical panel of the Luego pedal box is tight against the bulkhead panel, the hole pattern for the master cylinders (1 for the m/c & 2 for

the fixings) are also in the bulkhead so the whole assy (bulkhead, pedal box & m/c's) pulls up together with the m/c fasteners.

Here's another pic without the pedals in place to clarify.

[Edited on 15/3/04 by wicket]

|

|

|

wicket

|

| posted on 15/3/04 at 09:28 PM |

|

|

Lets attach the picture this time.

Rescued attachment Pedal_Box_1a.jpg

|

|

|

PioneerX

|

| posted on 16/3/04 at 01:36 PM |

|

|

Terrapin_racing,

I noticed you have the same brake fuild res-ies as me, how have you done the fluid level switch??? I'm stuck on this.

Thanks

Simon

|

|

|