thommy2

|

| posted on 17/2/04 at 08:57 PM |

|

|

Stiffer chassis, the solution!?!

HI there!

I would like some opinions here about a thought of mine.

Tractors, or the things farmes use for on the land, can be equiped with 6-cilinders. Those engines aren't equiped with balance axes, or whatever

you might call them in good english.

Those engines are part of the frame, and it makes them verry stiff right?

So, why not do that on a locost, we use a BMW six inline.

Why not bolt the entire engine to the spaceframe without rubber, the engine is fiberation free right??

Or has it been done yet?

reactions please...

Cheers

Thom

|

|

|

|

|

Metal Hippy

|

| posted on 17/2/04 at 09:08 PM |

|

|

I may be wrong, but my first thought is that with the stiff suspension in the kind of cars we're building you'll vibrate the thing to

pieces over time.

Tractors have biiig tyres and usually work on softer ground which I would imagine helps to dampen the vibration a lot.

Also if you've ever driven or ridden in a tractor you'll find that they're not exactly the most quiet of machines mostly thanks to

everything vibrating on them.

Cock off or cock on. You choose.

|

|

|

sweston

|

| posted on 18/2/04 at 01:30 AM |

|

|

My 2 cents worth, as I own a Tractor and locost.

My Massey Ferguson 28, yes the engine is bolted to the gearbox/back axle and they are the chassis. Tractors run at low revs, you have very low gears.

Its all about low down power and torque. It has a huge "heavy" flywheel that I need a hoist to lift. My tractor never gets much above

1500rpm so with a well padded seat, low pressure in the tyres and nice soft ground the vibration is acceptable. Also with the PTO you dont want

springs/suspension.

Top gear and full rev's and its a real scarry ride even on a nice smooth road.

If you ever see the Tractor Pulling monsters, well they prepapre the engine as if it was for a F1 race. Its all balanced etc as a proper race engine

would be.

Mind you a friend with an old Alvis looked at the tractor and remarked how similar his engine & gearbox where !

|

|

|

Metal Hippy

|

| posted on 18/2/04 at 01:59 AM |

|

|

To add to the above (as I said to Thommy in Messenger) I'd have said it may not be an issue on race cars that can be rebuilt after each race,

but that would involve a fair bit of cost... but would be needed if bits weren't to fail after a short while giving it some welly on a road that

isn't smooth as silk...

Cock off or cock on. You choose.

|

|

|

thommy2

|

| posted on 18/2/04 at 07:46 AM |

|

|

You are all right in that.

Just for information, I work at a farm to. I use to ride de Case CS86, quit a new puller. But when driving on the road, it's goes smooth as a

baby

The large advantage of a 6 inline, v12, is that there are no secundairy viberations. ( I just quote my brother, a car engineer, who worked at ferrari,

upgrading the Colombo V12)

So that's why I guess there are no damaging viberations.

|

|

|

andyps

|

| posted on 18/2/04 at 10:56 PM |

|

|

I guess the main difference is that the engine is designed as a stressed member for these applications.

The Ferrari F50 is one of few road cars which use the engine as a chassis member - it is bolted directly to the bulkhead and the suspension mounted to

it, but that engine was apparently based on the Formula 1 engine design.

Most of the engines which might be used in a locost were never designed for this type of stress to the castings.

Andy

An expert is someone who knows more and more about less and less

|

|

|

stephen_gusterson

|

| posted on 18/2/04 at 11:44 PM |

|

|

engines in old cars might be similar - my old boss said the engine in his tr4a was from a tractor design

atb

steve

|

|

|

thommy2

|

| posted on 19/2/04 at 07:47 AM |

|

|

ok, anyway

We'll just try it, I let you know when we suceed

|

|

|

Terrapin_racing

|

| posted on 19/2/04 at 09:15 AM |

|

|

Unlike McLaren F1, Ferrari F50's rear suspensions are directly bonded to the engine / gearbox assembly. This means the engine becomes the

stressed member which supports the load from rear axle. Then, the whole engine / gearbox / rear suspensions structure is bonded into the carbon fiber

chassis through light alloy. This is a first for a road car. Advantage: lighter still. Disadvantage: engine's vibration directly transfers to the

body and cockpit.

As described in the section on the chassis, the engine is also a part of the car's structure. The engine sits behind the driver, between the

transmission and the tub that forms the cockpit of the car. It is the only connection between the front and back of the car. The engine is therefore

called a stressed member, meaning that it carries load and is subject to mechanical stress. The level of stress that a Champ Car can exert on the

frame is one more thing that makes the engine so critical to success -- the engine is, mechanically, the entire midsection of the car's

structure!

The engine and drive train of a Champ Car make up about one-third of the mass of the car. In a severe crash, the engine and drive train assembly

separate from the front of the vehicle at a line just behind the driver in an attempt to protect the driver and dissipate energy.

Engine stressed member

If you engine is smooth enough not to transmit overbearing vibration to the rest of the chassis it makes a lot of sense to brace you chassis against

the biggest stiffest heaviest component it carries, and make use of its strength to do some of the load bearing work.

In 1963, a revolutionary chassis structure appeared in Formula One, the championship-winning Lotus 25.

Once again developed by Colin Chapman. Chapman used the engine / gearbox as mounting points for rear suspensions in order to reduce the width of his

car as well as to reduce weight.

In particular, reduced width led to lower aerodynamic drag. Of course, the engine / chassis must be made stiffer to cope with the additional stresses

from rear axles. Today, F1 cars still use this basic structure.

Along with the chapman strut this did find its way onto some Lotus road cars.

Although its use has been limited in Car use. It used to be a popular construction method for Motor bikes with bike like the Honda Super/Dream and the

GPZ900R using the design instead of a conventional chassis.

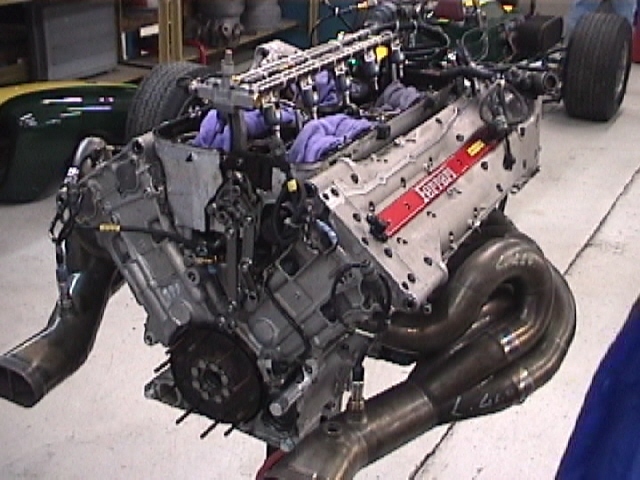

Rescued attachment ferrariengine.jpg

|

|

|

James

|

| posted on 19/2/04 at 09:19 AM |

|

|

quote:

Originally posted by thommy2

ok, anyway

We'll just try it, I let you know when we suceed

What about just following Cymtric's chassis mods- these will double the torsional stiffness (and reduce the weight!).

This is a simple and tried and tested route.

James

|

|

|

Terrapin_racing

|

| posted on 19/2/04 at 09:31 AM |

|

|

You could also use a slight compromise -

I you look at my photos you'll see in the suspension areas and engine mounts some yellow and green looking plastic materials these are

polyurethane and Green Nyloil (RS Components) machined as mounts and bushes on engine brace bars. Dampens out the vibration but des not move like

rubber!

Just remember that there was an issue with Jack Hammer users getting "white finger"

What do racers get if the vibration is through the seat of the pants?

|

|

|

200mph

|

| posted on 19/2/04 at 09:33 AM |

|

|

well white bum would be better than brown bum..... if you get that

mark

|

|

|

Terrapin_racing

|

| posted on 19/2/04 at 09:34 AM |

|

|

I believe it leads to long term stiffness - could be an advantage to some racers! lol

|

|

|

thommy2

|

| posted on 19/2/04 at 09:35 AM |

|

|

quote:

Originally posted by James

quote:

Originally posted by thommy2

ok, anyway

We'll just try it, I let you know when we suceed

What about just following Cymtric's chassis mods- these will double the torsional stiffness (and reduce the weight!).

This is a simple and tried and tested route.

James

James, what is that Cymtric's mod you talked about??

Well, going the easy way is simple, but not enough for inventors.

Indeed, instead of rubber, we could use less damping material, but we also have to adjust the enginemount. I will post a drwaing later.

|

|

|

James

|

| posted on 19/2/04 at 01:45 PM |

|

|

Read this thread:

http://www.locostbuilders.co.uk/viewthread.php?tid=1738

The long post by Cymtrix explains what you can do. He seems to know what he's on about (in my layman's view) and he uses a Finite Element

Analysis system to work out how to make the chassis stronger.

There's a a link somewhere to a site with a picture of the mods- anyone got it as I can't find it? Thanks.

HTH,

James

|

|

|

timf

|

| posted on 19/2/04 at 02:01 PM |

|

|

look in the photo archive under cymtrix

|

|

|

James

|

| posted on 20/2/04 at 10:26 AM |

|

|

Thanks Tim, there was also a link to a page that was presented as a Word document. A load of text at the top and a picture of the chassis below-

anyone.

Cheers,

James

|

|

|

flak monkey

|

| posted on 20/2/04 at 10:32 AM |

|

|

Yes i have a copy of that  if i could work out how to attach it to this meassage i would post it if i could work out how to attach it to this meassage i would post it  anyone know how to attach a file? Unless this

works.... anyone know how to attach a file? Unless this

works....

I think it is the one you mean, 2 pages of word document, with several pictures in it

Cheers

Edit: wow it worked

[Edited on 20/2/04 by flak monkey]

[Edited on 20/2/04 by flak monkey]

Sera

http://www.motosera.com

|

|

|

James

|

| posted on 20/2/04 at 10:47 AM |

|

|

Nice one that man!

Cheers,

James

|

|

|

pbura

|

| posted on 20/2/04 at 11:10 AM |

|

|

A US builder is using solid mounts on his rotary engine (another with little vibration), for limited street use:

http://autos.groups.yahoo.com/group/Locost_North_America/message/14810

Another benefit of stiff mounts is more efficiency in the drivetrain for acceleration. You would save that momentary lag as the engine winds up in

its mounts.

I like the compromise proposed by Rob earlier, using Nylon or the like. Best of both worlds, really, in that harmonics would be damped while most of

the stiffness would be maintained.

In my opinion, solid mounts are a "racer's edge" that probably wouldn't benefit a road car too much, while the negative

aspects would be noticeable. Probably a close analogy would be very stiff springing.

Pete

Pete

|

|

|

Terrapin_racing

|

| posted on 20/2/04 at 12:26 PM |

|

|

Tend to agree Pete. lot of racers use solid mounts - great, but there are penalties. I recently saw the havoc caused to the chassis tubes around the

engine bay of a Hawk single seater (cracked welds etc.) - hence my slight compromise.

Incidentally Nyloil is very inexpensive and some of the firms manufacturing polyurethane bushes will sell you the stuff in colour coded bars/blocks -

colour denotes shore rating (hardness) - . The four manufactured formulations of firmness (70, 80, 90, & 95 Shore-A) - they also can be very

helpful with advice.

Cheers

Rob

http://www.focussport.com/mounts.htm

[Edited on 20/2/04 by Terrapin_racing]

[Edited on 20/2/04 by Terrapin_racing]

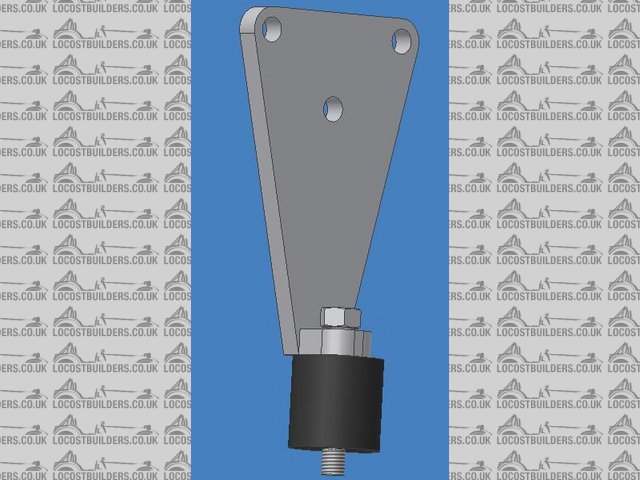

Rescued attachment polyurethane.jpg

|

|

|

thommy2

|

| posted on 20/2/04 at 05:59 PM |

|

|

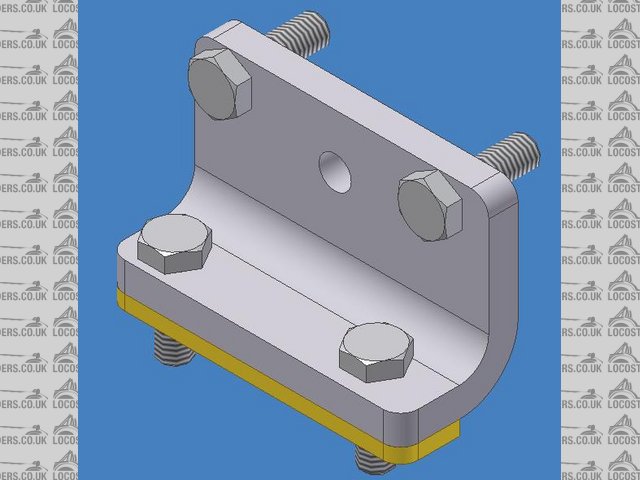

The Original

engine mount standard

This is the flexible aproach

engine mount new

This will give more strucute to the engine in the space frame.

Do you guys think it'll work?

[Edited on 20/2/04 by thommy2]

|

|

|

Terrapin_racing

|

| posted on 23/2/04 at 02:54 PM |

|

|

I think you need to isolate the upper section from the frame. In your drawing the bolts will effectively be a solid mount.

You should use two bits of insulator - one onto the engine mount bracket and one to the frame. Then with a joint of some nature between the two pieces

of PU. Mine use a dovetail.

Here is an Audi A3 polyflex bush mounting as an example

Rescued attachment a3.jpg

|

|

|

madman280

|

| posted on 15/8/04 at 12:24 AM |

|

|

engine as a stressed member

There was a one off 11 built in detroit in 1960 that used a slant 6 as a stressed member of the chassis. The 11 and 7 chassis' share allot in

common. You can read how Colin liked the idea enough to use it in formula 1. http://www.lotuseleven.org/open_exhaust.htm

|

|

|

drmike54

|

| posted on 16/8/04 at 05:07 PM |

|

|

Didn't the BAR Honda team blow some engines last year because the engine flexed excessivley under the chassis load and spun the bearings.

|

|

|