Syd Bridge

|

| posted on 16/1/07 at 09:11 AM |

|

|

Now, not to flirt with controversy, but.........

A GRP monocoque CAN be a dangerous thing. If not properly carried out, with meticulous choice of materials and orientation,

explosive catastrophic failure is in the realms of reality. (This means NO csm, NO woven roving or cloth,NO poly resin. Heck, you may as well use

metal. )

Ali is a lot safer, and can be quicker and cheaper to build. I'm amazed at what some people see as progress, thinking that nobody has done what

they are attempting before.

Drawn it, built it, seen it fail...now know better than to try it again.

Cheers,

Syd.

|

|

|

|

|

Volvorsport

|

| posted on 16/1/07 at 07:47 PM |

|

|

that chassis design has been about for oh - 40 years , not bad eh ? ive seen them in accidents and they stand up very well indeed - oh did i mention

its big brother won the motoring news tarmac rally championship 'twice' oh and er the British GT series .

so what would you think of the bonded honeycomb grp/kevlar thats used in aeroplanes for the mosler chassis ? thats won the british GT series aswell ,

not a dig , but i think you knock it too much .

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

kb58

|

| posted on 16/1/07 at 08:30 PM |

|

|

While a car/boat/airplane can be made from many differnent materials, the difference between a good and a bad design is how the material is

used. How thick, what grade, what heat-treat, which composite material,what weave orientation, how many layers, which epoxy, cure temperature, etc.

The true design work is in the details, and there's a big difference between fabricating something and designing it. It's what separates

amateur builders from the pros.

[Edited on 1/16/07 by kb58]

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

Dick Bear

|

| posted on 17/1/07 at 05:34 AM |

|

|

Kurt, I agree with you on that. I'm encouraged that you seem to be opening a crack in your previously expressed position of zero tolerance of a

monocoques.

Dick Bear

www.marketpointproductions.com

|

|

|

TheGecko

|

| posted on 17/1/07 at 09:26 AM |

|

|

I didn't think Kurt ever said he was anti-monocoque. I think his concern (which I share) is amateur designed/built monocoques, which is a whole

other thing.

If there was a "Build Your Own Alloy Monocoque Sports Car for $2000" then there may be a baseline to work from. But in the absence of

that or anything similar it has to said that building your own monocoque is a very different proposition to building your own spaceframe. I'm

not saying it's impossible or not to attempt it. Where I agree with Kurt (although not as stridently  ) is that such an endeavour must be

entered into with eyes very wide open. I suspect that a monocoque will not respond to a "looks right, is right" design philosophy. The

other alternative to actual design theory is to just overbuild it (ie 1/4" plate etc) which kinds defeats the purpose. ) is that such an endeavour must be

entered into with eyes very wide open. I suspect that a monocoque will not respond to a "looks right, is right" design philosophy. The

other alternative to actual design theory is to just overbuild it (ie 1/4" plate etc) which kinds defeats the purpose.

Again, I'm not saying it shouldn't be tried. I've often considered a monocoque version of my chassis but I know that I don't

have the engineering knowledge (yet) to be sure it's safe. Or more so, convince an engineer and the registration authorities that it's

safe so I can drive it on the road. If you can build one then publish a book on how - I'm sure the Locost community will all make a beaten path

to your door to buy a copy each.

Good luck and looking forward to progress,

Dominic

|

|

|

Syd Bridge

|

| posted on 17/1/07 at 09:34 AM |

|

|

quote:

Originally posted by Volvorsport

that chassis design has been about for oh - 40 years , not bad eh ? ive seen them in accidents and they stand up very well indeed - oh did i mention

its big brother won the motoring news tarmac rally championship 'twice' oh and er the British GT series .

so what would you think of the bonded honeycomb grp/kevlar thats used in aeroplanes for the mosler chassis ? thats won the british GT series aswell ,

not a dig , but i think you knock it too much .

OK Smartarse;  I'm not knocking it, just pointing out that a csm mono, done properly(? if that is possible) would be very heavy, on a

stiffness and strength comparison of like for like with hybrid composites. I'm not knocking it, just pointing out that a csm mono, done properly(? if that is possible) would be very heavy, on a

stiffness and strength comparison of like for like with hybrid composites.

The inference in your post is that the GRP mono you point to is doable by anyone. Plainly, definitely not the case as you expanded in your latter

post. A glass/kevlar honeycomb sandwich is far, far from a 'GRP' monocoque. If you understood the materials, you'd be a little more

reserved in your wording.

A properly done sandwich, as in current racecars, can be near to bullet proof.

The difference between a 'grp' monocoque and a proper sandwich construction being two completely different worlds. As I said, NO csm, NO

poly resin, NO woven materials.

If you want to waste time and materials on glass, go ahead. Not 'cost effective'. You are best to use a HS Carbon. The end result will be

lighter my magnitudes, stronger by similar magnitudes, and on specific strength/cost/weight indices by far the most effective option.

To consider building a grp mono, in my experience and opinion, is pure folly, and should not even be contemplated by anyone in their home workshop,

unless they can properly engineer same. As can be said for any type of chassis.

I know what Kurt's concerns are, and to a certain degree I concur.

A tube frame chassis is doable by nearly anyone in their shed, but can be as dangerous as a badly done sheet monocoque, or any other material. Indeed,

the tube really has more scope for danger, with bad welds, and the amount of them, the prime area for concern. How many dodgy chassis welds have been

presented on this site by proud owners of new creations? Far too many, and noone wants to 'offend', so say nothing . They all have a big

hug and congratulate the owner of the new deathtrap creation.

On this forum, the help from like minded creators, has probably stopped many a disaster. And Mr.Bear and many others can 'have a go',

learn from scratch, and hopefully end up with a safe vehicle they're proud of. Graber, Fred WB and Alan B are excellent examples.

Oh, Mr. Volvorsport, I design, make the tooling, and actually build the stuff I talk about. Have done for far too many years, and at the very top of

the sport, in some instances.  There are a few things taken for granted in motorsport today, that many said 'couldn't be done',

that originated in an old milking shed on the Isle of Wight. A lot of it crossover technology from racing yachts, and yes, aircraft!The same shed

that I rent and work in, mostly alone. There are a few things taken for granted in motorsport today, that many said 'couldn't be done',

that originated in an old milking shed on the Isle of Wight. A lot of it crossover technology from racing yachts, and yes, aircraft!The same shed

that I rent and work in, mostly alone.

Cheers,

Syd.

Their exists far too much MISINFORMATION on the internet, yet alone on this forum!!!!!!

[Edited on 17/1/07 by Syd Bridge]

|

|

|

Syd Bridge

|

| posted on 17/1/07 at 09:54 AM |

|

|

This whole thing has got VERY off track, so here's a repeat of what I wrote on the first page.

Now, everyone let poor Mr. Bear go and build his car!!!

quote:

Originally posted by Syd Bridge

This whole materials thing needs to be put into perspective.

Some of my 'bread and butter' comes from designing and building monocoques, in various forms and materials.

The racecars that are still built in ali are certainly lifed, but usually come to grief well short of that.  Lotus saw fit to do their modern cars

with ali mono's, so for specialist applications, it's ok. Lotus saw fit to do their modern cars

with ali mono's, so for specialist applications, it's ok.

We'll rule out carbon, because without the proper gear (autoclaves, car size ovens and such), and the tooling costs, it is not worthwhile for

home/garage builds. And not done properly (this means NO wet layups!!!!), can fail catastrophically.

I've seen no mention of steel sheet mono's here yet. Why not? After all, your car is a steel mono. A home build steel mono can end up much

better than a spaceframe, and lighter when you factor in the panelling of the spaceframe. After all, the sheet mono is only the panelled spaceframe,

without the tubes!

I did a prototype project for a local company a good few years ago. When all the numbers were crunched, and 'street cred' and sales value

were factored in, the decision to go with a 1.2mm stainless sheet mono was easy.

Not the lightest, but easily built with a mig welder and the basic cutting and bending gear that was to hand.

The stainless sheet will last forever, is not too difficult to work with, and relatively easily patched without special welding or any other tools.

If I were Dick Bear, I'd be having a serious look at a thin sheet ss mono. ~1mm plus stiffeners strategically placed.

Cheers,

Syd.

Edit: I just reread some of the above posts. For the ali bonding adhesive, Bondmaster do a 'filled epoxy' one part that is cured at 120c.

All the glue companies do a similar product. You'll tear the ali before the glue lets go........... that's if you've prepped the ali

properly in the first place. Not expensive at all, just the oven costs a bit.

[Edited on 13/12/06 by Syd Bridge]

|

|

|

Volvorsport

|

| posted on 17/1/07 at 06:54 PM |

|

|

i know what you do syd !! i have spoken to you before .

but i still think a home taught laminator could produce it as long as they were good at it .

if you design for strength , the stiffness is there .

the darrian chassis uses polyester resin and csm/woven roving/kevlar and carbon in all guises .

yes it would be better in epoxy but it can be done .

so , im just pointing out it can be done at home for the specialist builder .

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

Syd Bridge

|

| posted on 18/1/07 at 09:30 AM |

|

|

quote:

Originally posted by Volvorsport

............the darrian chassis uses polyester resin and csm/woven roving/kevlar and carbon in all guises .

To use that mix of fibres, in anything, shows an obvious and possibly dangerous lack of understanding of the material properties.

To use them in a chassis tub only magnifies the dearth of understanding by many times.

Then to put poly resin into the equation, utter madness.

They've got away with that for as long as they have because of excess material. Way, way too much excess, and the weight that goes with it.

Kevlar has no where near the acceptance and use in stressed applications as carbon and hs glass, and for very good reason. As for mixing it with poly

resin, verging on reckless criminal negligence and utter stupidity.

I don't put the words above lightly. The majority of racing yacht, and car, failures that I've witnessed have involved kevlar. Kevlar has

its place and uses, and does them very well.

There seems to be a dangerous lack of composite engineering knowledge all round. No home builder should even contemplate a resin/fibre tub unless he

has a complete and thorough understanding of the processes involved, and the engineering properties and shortcomings of the fibres and resins intended

for use.

Steel tube or sheet is safer, and within the realms of home builders with ease. Aluminium is only a little more difficult, and requres a little more

thought and engineering input.

Cheers,

Syd.

I should have a bigger autoclave running in 6 months. When Darrian want a proper tub, safe and lightweight, designed and built, you know where to find

me.

THAT'S IT. NO MORE.

[Edited on 18/1/07 by Syd Bridge]

|

|

|

NS Dev

|

| posted on 18/1/07 at 09:42 AM |

|

|

Sorry to carry it on Syd, but you know as well as anybody else, and this is very often the case with competition cars, that the Darrian works, and

works extremely well.

As tarmac rally cars they are both very safe (proven in a number of big accidents) and extremely quick, and, relative to most rally cars, very

light.

As circuit cars, just look back a few years to the success of the Swansea institute cars, running millington 4 cyl engines against the big boys in GT

racing and doing very nicely.

I know nowt about composites, thus won't be using them, (at least for the foreseable) but poor or good or indifferent as it may be, the darrian

is a well proven and highly successful competition car.

(hell they even won loads with the horrid imp suspension still used when they were still Davrians!)

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

Syd Bridge

|

| posted on 20/1/07 at 12:30 PM |

|

|

[They've got away with that for as long as they have because of excess material. Way, way too much excess, and the weight that goes with it.]

Your 'lightweight' is my 'battleship'.

Please read what I posted fully, and without the influence of alcohol!

Questions will be asked after the tutorial.

Cheers,

Syd.

|

|

|

gottabedone

|

| posted on 20/1/07 at 02:24 PM |

|

|

my ten pence worth

Guys,

We all seem to agree on so many things here but we also disagree on the same things and are slagging off each other either directly or implied.

IMO a semi-monocoque structure that is implemented correctly, is the strongest and most suitable structure for our type of use full stop!.

What material that this structure is made of is down to cost and the skill of the individual. These days people are willing to pay considerable

amounts of money for over-engineered parts just because they look good (carbon dashboards etc)

Looking through this forum, there are many topics where an individual has made thier own chassis - with an admission that it was the first time that

they had done any metalwork and/or welding, which I think is both foolish and dangerous but the responses are generally polite and encouraging. Mr

Bear here has emmense skill with sheet metal but because he followed the monocoque route and didn't unwrap his welder and learn to weld on his

front suspension he is continually flamed. Look how many posts there were last year about the front wishbone mounting points for the shocks and the

catastrophic failures that ensued, not to mention the numerous admissions of twisted chassis - give the man a break - he asked for advice!

I have an interest in both sides of the chassis arguement - I love sevens and their simplicity but equally I am a structural engineer and know the

benefits of the monocoque. I am a time served apprentice in structural engineering (1000 hours with hammer in hand and then another 6 weeks of

advanced stuff a number of years later) where my skills lie in the use of mainly Ali, be it bonded/bolted/riveted or whatever.

Anybody that has worked with sheet metal in it's various forms of heat treatment, will know how difficult it is to form to a specific

size/shape/flatness etc. We are talking to tolerances of thousandths of an inch not halfan inch and pull in the gap.

Many posts have had replies saying "make a model from whatever material and see how it acts/reacts". This is basically sound un-technical

advice, but please know the basics behind the point of this exercise. Here are a couple of links that will help explain the forces that our

structures need to withstand and how you may engineer for them:

http://instruct1.cit.cornell.edu/Courses/ansys/shell/index.htm

(Youngs modulus will show you how a structure will behave under a given load in a given direction. It will allow you to see the point at which a

structure will fail under a given load)

another:

http://www.nps.navy.mil/avsafety/gouge/stress.htm

Syd and Mr Bear here are gods in their field (IMO again) use them as references for their skills - don't flame them for being RIGHT but learn

from their knowledge of structures and techniques.

regards

Steve

|

|

|

Syd Bridge

|

| posted on 20/1/07 at 06:23 PM |

|

|

There is only one God, and I am not He !!

Cheers,

Syd.

|

|

|

airframefixer

|

| posted on 22/1/07 at 08:05 AM |

|

|

a note on primary structural metal bonding.

much like the process syd uses to build composite structures, primary structural metal bonding REQUIRES an equivalent level of knowledge, skill, and

equipment. not to mention extremely expensive materials.

unless you know EXACTLY what you are doing, do not soley rely on bonding metal with an off the shelf adhesive/resin sytem. and i do have to agree that

polyester resins are inferior and should be limited to secondary structures, fairings, mouldings etc.

this does not mean that it cannot be done by someone outside of the motorsports/aerospace industry. preparation is critical for a sucessful metal to

metal bond.the process'shat i know apllies to 2024-t3 this alloy, so there are no guarentees for other alloys.

Phosporic acid anodization(PAA developed by boeing, deposits a layer of pourous oxide film on to the metal, leaving a suitable bonding surface, this

requires tanks of dionized water, 12% phosporic acid solution, anodizing euipment etc. and then you need the bonding primer, very expensive with a

limited shelf life. Boeings spec must be follwed to the T to guarantee performance, i have yet to obtain this document, so i cannot give specifics.

once prepped your ready to bond. if your serious about metal bonding, hysol/henkel/loctite, offer adhesives in film form that can be bonded at room or

elevated temperatures. EA9309.x, EA9309, EA934, Magnolia 6398 are all suitable metal bonding adhesives and offer excellent performance ONLY if you

follow the directions, i cannot stress this enough. the joint much like a aluminum or composite monocoque, must be engineered to take advantage of

advanced resin systems.

another method commonly used now in the field is the PAsa jel method, which is a jel applied to the substrait, and converts the surface into a

suitable bonding surface. this eliminate the tanks and anodizing equipment, but bond primer is still required, and once primed the part has a shelf

life. the shelf life can be extended by an elevated temperature post cure and stored for later use. one avenue i may prusue and i can say is by far

doable at home is prebond metal. i have used this in the helicopter industry in its 7075-t6 variant, it is backed with a scrim cloth that can be

pelled away to expose a already prepped metal, one downside is that its pink. its really pricey too, unless you have a guy on the inside at the place

you used to work. there do exists other methods but im not gonna type all night.FLP,panta,sol-jel...

and i stress again that the process i just talked about are certified for repair on various aircraft, NOT manufacturing, you will never get that out

of boeing, airbus, BHT,eurocopter, their process are different at the manufacturing level, are proprietary. the field metal bonding methods are design

for small repair doublers, core replacements, etc, not so you can manufacture your own wing plank/skin.

it was mentioned earlier in this post that a single component adhesive was used on various aluminum parts and the aluminum "ripped apart"

during destructive testing, could the authour elaborate on the alloy type and thickness if know. these results are impressive to hear, but really

theres more to it.

also i understand that various automotive aluminum parts are bonded during assembly, with room tempurature cures with minimal preparation. dont let

this confuse, as there is no wonder glue out there thats gonna get squeezed out of a tube and hold one of the worlds finnest sports cars together, the

elise. was the chassis anodized somewhere during the pre assembly stage. was there a protective cover over the bonded areas. all things that we dont

know and lotus isnt going to tell us.

.... on ther hand metal bonding for non primary structural reasons is totally doable for the motavated individual. i have excellenty results by simply

abbrading with a maroon scrotchbrite pad, rinsing with water, alumiprep acid wash, rinse, chromic acid conversion, rinse, air dry, dont touch it BTW,

and bond with a decent epoxy paste adhesive.

i hope this was informative, and i personally know enough to know that primary structural metal bonding CANNOT be done safely, economically, realiably

at anything other that the proffesional/industrial level.

question for Dick..

are you building an aluminum moncoque to extrapolate maximum performance out of aluminum and the monocoque design?

or just for the novelty?

Andrew

|

|

|

NDC790

|

| posted on 22/1/07 at 05:21 PM |

|

|

Bonding?

Thanks Andrew, I've been waiting for a post like this.

I've been looking into bonding for the past month or so, been to all sorts of web sites ie Loc-tight, cotronics etr. Also have investigated The

Lotus and Morgan chassies and have found many bond types and spec's, but like you mensioned, no prosses of bonding.

I have done some repair work on both the Mogan and the Lotus, and it seamed to go quite well, which is why I'm keen to explore the possibility

of building a one off chassie of my own.

Do you think this is possible, and what would be the hurdles as you see them for this type of project?

Many thanks,

Nick.

|

|

|

airframefixer

|

| posted on 23/1/07 at 09:50 AM |

|

|

possible.. yes... will you safely , reliably be able to get the best performance from the materials alone by just bonding... i still don think so.

lotus still supplements the bond line with mechanical fasteners. if you were to do this, i would consider the chassis to be a disposeable item as

bonds do degrade over time just like some metals fatigue, and aluminum can easily corrode in a bond line.

an excellant example is the aloha 737 that had a lap joint failure and had its roof torn open in hawaii. the point im trying to illustrate is that lap

joint in the 737 is bonded and riveted. just the rivets alone are sufficient for the structure, but the addition of an adhesive sealant between the

two sheets, reduces the load taken by the fasteners and therefore prolongs the life of the joint. those machines were high cycles in a humid, and

corrosive environment. the bond between the laps eventually failed due to corrosion of the metal and required the fasteners to take 100% of the load

in a localized area. due to the frequent and repetative cycles of the aircraft the joint was unable to sustain the strains and cracks propogated from

the rivet holes.

if a disbond(not to be confused with a delamination) were to occur the fastener would still provided some joint strenght, but at a much lower amount.

its a safety margin and in addition, its a clamp most likely required during the bonding process, and they just left it there.

however, i will be taking advantages of panel bonding in my vehicle which will use a steel/aluminum hybrid semi monocoque. the lightweight steel

bulkheads,longerons and diagonal bracing, will carry the suspension loads into the aluminum skin which will be bonded AND riveted into place. i dont

have the capabilities to just bond them on. the aluminum will be .063 2024-t3 sheet, which is standard structural aircraft alumnum. i will use the

process i described earlier to prep the aluminum and use a room temperature cure 2 component rubber toughend epoxy resin for added peel resistance.

the rivets are 5/32 monel cherryax rivets that are 100% mandrel rentention rivet with equal shear strengh to their aluminum solid cousins of the same

size. i will use an 426 AD solid rivets where their is sufficient acess to both sides for the tooling(gun and bar).

my design relies upon the steel structure to be adequately rigid for safety reasons, so if there was no aluminum panels, the car, in my opinion would

still be safe to drive, but would not be rigid enough to make the most of the suspension system, i plan on using a spring rate equal to the corner

weight , and the wheel ratio is 1:1.

the aluminum panels are there to increase the rigidity of the chassis for the least weight penalty and to provide some intrusion protection for the

occupant. basically instead of adding additional tubes for rigidity and then panelling the car, im asking the panneling to take more of a structural

load.

|

|

|

Fred W B

|

| posted on 23/1/07 at 11:19 AM |

|

|

The composite guys might be interested in Dennis's latest chassis ideas

here

Cheers

Fred W B

|

|

|

Chr!S

|

| posted on 23/1/07 at 01:32 PM |

|

|

My 2ps worth:

Having done some recent research (chassis design project for university  ) I wonder if you've seen the lotus elise chassis? Its a bonded

aluminium monocoque just like what you are designing and might be worth a look ) I wonder if you've seen the lotus elise chassis? Its a bonded

aluminium monocoque just like what you are designing and might be worth a look  For suspension a good solution would be to build a separate

cage/partial frame which is then separately attached to the monocoque, this is a growing trend in monocoque design. For suspension a good solution would be to build a separate

cage/partial frame which is then separately attached to the monocoque, this is a growing trend in monocoque design.

Another way to simplify things is to use the engine as a stressed member - as seen in some F1 and high end ferrari applications where the suspension

bolts onto the block - mainly to save space; I couldn't say whether this could be a good idea or not though...

Seems like a long thread - How is the design progress going?

Chris

|

|

|

NDC790

|

| posted on 23/1/07 at 09:37 PM |

|

|

Thanks Andrew, my idea was to build a aluminium monocoque, from extrusion and sheet, whick would be bonded and riveted (or simular mechanical

attachments). This would all be under a steel roll cage which would also link the front and rear subframes, also steel construction. The front

subframe would mount the front suspension, steering rack and pedal box, while the rear subframe would mount the rear suspension and cradle most of the

engine waight.

What do people think? Be nice please

Andrew, I would be interested to hear about you chassie design, as it sound very simular to my plan "B".

How are you going to coat your steel frame, powder coated? Would you mind explaining you bonding method again, in a way a mear mechanic would

understand.

Many thanks

Nick.

|

|

|

airframefixer

|

| posted on 24/1/07 at 12:52 AM |

|

|

quote:

Andrew, I would be interested to hear about you chassie design, as it sound very simular to my plan "B".

Nick

its bassically, a square steel tubular structure with shear panels riveted to it. its is a semi monocoque tub. there is a difference and it appears

the terms are being confused. a monocoque is a structures in which the skin bears the loads. a pop can is a perfect example, stress skin caped by two

bulkheads. a semi monocoque utilizes a light weight inner structure than shares the loads with the stressed skin.

on my design, the light structure beneath the stressed skins is comprised of former rings/bulkheads made from 1x1x.062 square steel tubing. the

bulkheads are connected via various tubing types and sizes. the outer panels form the stressed skin. of the tub. there is also 3 completely boxed in

sections made from aluminum that i believe will improve stifness. two large boxed sills, and the third being under the drivers legs. the intent is to

spread the two skins apart via formers/channels etc, by doing so when load perpendiculary the top sheet takes a compression load, and the bottom

recieves a tension load, the two resist each other and the result is an extremly stiff structure. the i beam principle.

as i said earlier, the square tube steel substructure is designed to be stiff enought by itself to be safe, but the addition of the box sections and

shear panels is intended to greatly improve stifness, and to allow the suspension to do its job.

once the frame is completely welded, it will remain clamped in the jig while holes are drilled for the fasteners, and the panels will be attached will

a massive quantity of clecos. why am i going to do this. because it will help the chassis remain straight and true once removed from the jig, and the

panels will preload the chassis back to its intended position once fastened. and, yes there will be some internal stress.

as for the finnish on the frame i will be using endura EP-2C 2 component epoxy primer/sealer. the frame will be sanded to give a rough texture, then

cleaned with lacquer thinner, let it dry and immediately before priming, doing a finnal wipe with a 50/50 mixture of water and isopropal alcohol. wipe

dry, this mixture is extremly pure and also acts as an anti static agent, tack cloth it, and spray the primer with a conventional gun, i use a badger

model 400, i highly recomend it for small jobs and its sprays endura well. endura does not do well with HVLP guns. once primed i have a window of

approx 72 hrs to apply a compatible bonding adhesive, the reason, after 72 hrs, during the 72 hrs after application, the matrix(resin) has not

completely cured and another compatible substance can cure into it. this is called a cohesive bond, which takes place at the molecular level. after to

72 hrs, the surface must be given a "tooth" and an adhesive bond will result, simply a mechanical bond.

thats the steel side of it, but before i forget, on a another note: when repairing or bonding to a cured epoxy laminate use only an epoxy resin. a

cured epoxy laminate when abbraded to get a adhesive bond can expose unreacted amine, which is an ingredient of epoxy hardener, the amine will inhibit

the MEKP catalyst and it will not cure properly. make sure your resins/primers/paint systems are compatible.

72 hrs, the clock is ticking. the clad 2024-T3, can be preped now. start out by abbrading with marron scothcbrite, in a tank/sink/ or under a tap of

clean water. abrade until the metal will support an unbroken film of water, this is called a waterbreak test. if itwill not support a film of water,

there is grease or oil on it. rinse all the residue off and let it air dry, or dont. you just gonna get it wet in the next process, phosphoric acid

was. just douse it with this chemical and watch the fuild turn into a milky white colour. let it sit for a minute or so and let the acid etch the

metal, but follow the directions. this is sold under various names, brands, number etc. dupont 225S, alumiprep, metal prep. etc.

rinse it off thoroughly and let it dry, once dry, apply the chromic acid solution. trade names are iridite alodine, 1200s, etc, all are slightly

different but achieve the same thing essentially. they chemically convert the surfrace to a hard oxide layer that aids in retarding corrosion,

(corrosion cant be stopped, but simply slowed down) and promotes adhesion. apply the solution, let it stand for a period of time determined by the

strenght of the solution untill it turns a gold colour, rinse it off let it air dry and let it sit for a period of time, maybe this process should be

started, before priming the chassis. it will harden over time. once im readty to prime the aluminum, ill wipe it down with the same 50/50 solution of

iso and water, wipe dry, tack it and spray Desoto super koropon primer. this stuff is a boeing spec primer and will hold up to the most caustic

fluids, skydrol, even some brands of paint stripper. i had a horiblle time getting this removed from the tail of an A/c that has a repair doubler

painted with this stuff. very impressive, super hi adhesion characteristic. once the panels are dry, but still within its cohesion window, cant

remember for this primer, i will apply a rubber toughend epoxy adhesive, (film preferably) or paste and rivet the panel into place with 5/32 monel

cherrymax rivets. thats the process.

caveate emptor. i have designed my own process based on the experience i have gained using approved methods and correctly using the products

previously mentioned. i feel that every thing that i do will improve corrosion resistance and improve fatigue life to my chassis due to supplementing

the mechanical joints with a reliable adhesive bond.

and a final note on any use of these chemicals, resins etc. none of this is locost, if it is, it most likely time expired product. alodine is for

aluminum only, do not do any of the above on stainless, high strenght steel alloys etc. alodine can cause hydrogen imbrittlement which will ruin steel

and most likely you day and your car. epoxy resins are toxic, were gloves, their fumes are heavier than air, but i always wear a respiration when

mixing and laminating. epoxy/linear polyurethane primers/paints contain isocyanates, they will FYULABA. they break down your central nervous system,

protect yourself, so you can enjoy you car do your research first before attempting anyof this, this is dangerous stuff. but if you want improve the

service life of and bonded aluminum structure, do your research and DONT try to re invent the wheel and think youll get away with it. this has been

around since the 60's lockheed, boeing, BHT, airbus, and many other firms have spent millions learning how to extrapolate the max life out of

these structures.

Andrew

|

|

|

NDC790

|

| posted on 24/1/07 at 08:35 AM |

|

|

Thanks,

I presume most of the bonding companies will be able to to advice me/supply me with the materials to prep in my aplication?

How long do you expect you chassie to last? And (hopefully this will never happen) after any damage, is it possible to make repairs to your chassie

without having to rebuild it?

Sorry for all the questions, I seemed to have developed an unheathy intrest in this subject now!

[Edited on 24/1/07 by NDC790]

|

|

|

airframefixer

|

| posted on 24/1/07 at 03:08 PM |

|

|

quote:

Originally posted by NDC790

Thanks,

I presume most of the bonding companies will be able to to advice me/supply me with the materials to prep in my aplication?

How long do you expect you chassie to last? And (hopefully this will never happen) after any damage, is it possible to make repairs to your chassie

without having to rebuild it?

Sorry for all the questions, I seemed to have developed an unheathy intrest in this subject now!

[Edited on 24/1/07 by NDC790]

sorry having troubles here with the internet.

no wories man, glad to help. just remember that unless you know xactly what you are doing, do not relly on bonding alone. use sometype of fastener

with it, the fasteners allow the adhesive to do its job, in our case.

look into ITW devcon for products. they sell adhesives, primers, metal cleaning solutions, and application equipment.

as for the life of my chassis,i dont know, as long as every other locost. maybe more, maybe less.

the key to getting maximum life out of my car, is proper fabrication techniques, using large radiuses on bends, roughly 3x times material thickness

for 2024-t3, polishing edges to leave a smooth surface with no stress risers. deburiing, yes its tedious, but im used to doing it this way, and its

the only way to do it. if youre going to use a high tensile strenght aluminum, it must be preped a certain way to reduce the chances of it cracking.

80% of the damage i have seen on nonpressurized, or a atleast a nonpressurized portion, aircraft has resulted from poor manufacturing quality, rough

edges, or human interaction. meaning its removed repeatidly, scratches from screwdrivers that slipped, or inadequately fastened, the fasteners and

their supporting structure took too much of a load.

i expect corrosion not to be an issue, with the extent that iam prepping my parts. expoxy primer on the outside of the tubes. and douse the inside

with hot linseed oil, and shake the chassis around, or unload a can of LPS3 on the inside via a small hole. its should protect the inside of the

tubes. either way the inside will be welded shut, and i dont anticipate it going swimming with it.

if i find small cracks propogating from radiuses, then i will either repair the section with a doubler/patch as per standard aircraft repair

practices, AC43.13B is the book, loads of info in there regarding repairing aircraft. if the problem reoccurs, replace the panel with a thicker one

one gauge thicker. this will require de riveting, have fun doing those with cherrymax rivets, there's only one right way to do it, and then

breaking the bond(heat gun, putty knife, and hammer).

but really the aluminum is not taking the concentrated loads of the suspension components, thats taken by the steel bulkheads. so i really dont

anticipate that much, if any, cracking, due to propperly preparing the bond line to retard corrosion, and using a good adhesive sealant, the loads

will be spreadover the large surface area.

im of the opinion that anythings can be fixed. it just depends on how much work is required. lets be realistic here if every part of the chassis is

bent in some way or another from one impact/accident/incident. fixing the chssis is going to be the least of my concerns. if i walk away from a shunt

that bad, ill be happy enough. then again, may be more work to make that many, or that large of a repair, than to make a new chassis. but let say i

had a substantail head on with an immoveable object, i have body work and a collapseable cone for starters, then the wheelsand suspension components,

then the foot box, if that gets damaged and depending were, it will half to get disasembled and repair with new material, and mostly likely a repair

jig will need to be constructed. however if it is that bad, ill be a few inches shorter and be on crutches for sometime.

Andrew

[Edited on 24/1/07 by airframefixer]

|

|

|

NDC790

|

posted on 24/1/07 at 10:58 PM posted on 24/1/07 at 10:58 PM |

|

|

Again, many thanks.

I now think I'm a few steps closer to my final design. I will take on bord your coments about the correct materials and preporation when doing

the bonding on my frame, I also think I will keep the bonding to a minimum, you know the bonding will be to level of my knowledge, i.e. LIMITED! The

main part, the more complicated, will be fabricated in steel, and welded, where I have alot more knowledge and experience. It's where the two

materials meet which was my bigest concern. In these areas I think I rely mainly on mechanical means, backed up by bonding to cut down any movment and

posibly to absorb some shock transfer. What do you think?

Effectivly reducing the aluminium in the fame to four, maybe five main peaces, the floor, two sides (extruded RHS), front scuttle/bulkhead and

possibly the tunnel/backbone. It's simple, and simple is normaly best? for me anyway!

I now have to transfer these IDEAS into drawings, with the dreded soilid works, so I can post them on here and then be shot down in flames and sent

back to the drawing bord!

Anyway, good luck with yours.

|

|

|

Dick Bear

|

| posted on 27/1/07 at 03:25 AM |

|

|

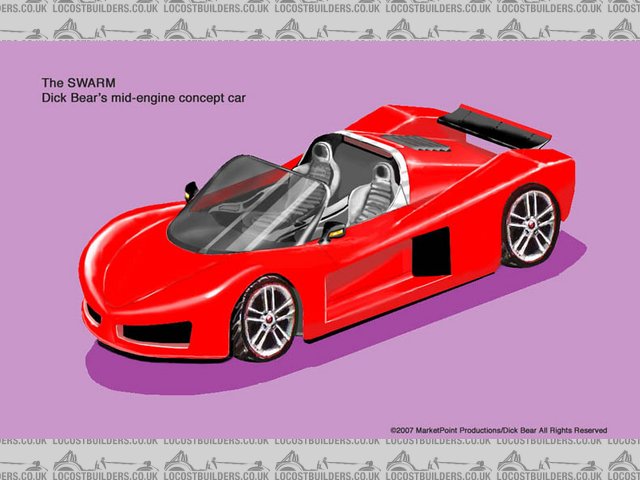

The SWARM M8

Well, we seem to have the issue of adapting a monocoque to a street vehicle resolved to one degree or another. Thank you all for your comments,

recommendations and views per my request for suggestions. Each opinion (pro and con) has been noted and will be considered once the project is

begun.

While mulling over the different suggestions I have been designing what I would like to have the exterior of the vehicle look like. Understanding

that likes and dislikes of a carís appearance is a personal thing (remember several at GM thought the Aztec was cool enough to go to full production)

and knowing I will probably receive the full gambit of critique for the design, Iím throwing caution to the wind by presenting it here on Locost

first. You may flame it, accept it and/or offer suggestions.

Obviously I think itís cool and hope that my body shaping skills are up to the task of creating the real item based on my attached PhotoShop

rendering. The Swarm M8 will be a monocoque frame with a longitudinal V8/transaxle drive train the specifics of which I am still exploring. As Iíve

noted before, Iím not an engine expert of any sorts and come to this love for cars as a designer/fabricator not a mechanic. Therefore, I welcome any

suggestions for what could be married most effectively in the area of power plants. If you know of and would like to suggest specific engine and

transaxle combinations Iíd welcome that from you.

Now Iíll run for cover and peek up just long enough each day to see what comments have been posted!

Dick Bear

Rescued attachment Swarm M8.jpg

www.marketpointproductions.com

|

|

|

Doug68

|

| posted on 27/1/07 at 11:17 AM |

|

|

Now living in Salem surely it has to be a small block Chev with 4 barrel Hollie on top?

For the trans I'm going for a Porsche Boxster unit.

The best would be to get a Porsche G50 but they more money for a good one compared to the Boxster unit.

However as yet I've not actually seen anyone use a Boxster unit I may have bought an expensive ornament for the garage, and mating plates etc

will be custom as a result.

The Audi, Renault units referred to often here are more or less non existent in the states.

I'm also lead lead to believe the trans in Fieros were all rubbish except the very last generation of them.

|

|

|

|