Fozzie

|

| posted on 29/7/05 at 08:30 PM |

|

|

Hi Pat,

Yes, it can be a problem, my diagonal was already in place (part of the MK roll cage ensemble), and I had no alternative but to weld the horizontal

on.

I have looked at my old pics of the harness mounts in the early stages, and I must say that they are/were built very much stronger than the pictures

depict. In fact remarkably similar to the picture you posted (blue car).

I can assure you that if I had any doubt that they were not strong enough, or couldn't take an impact and 'roll', I would have been

the first to 'kick-up'!

As it is, I am not using 'their' harness mounts for the reasons that have been stated many times in this thread, 1, the datum point was

too short and 2, they were askew to the seats.

That is why I suggested that you actually looked hard at the way they are done, as a photo cannot give you the 'true' picture (3D).

Unfortunately mine are now panaled in, so I cannot give you any pictures from all angles.

This isn't about upsetting any of us, we all want what is best for you to get your car on the road, but safely for your sake, and also of course

for your passenger.

If we can impart our collective experiences to help you and others realize exactly what weight and force the harness mounts and belts have to endure,

and that 'life' does actually depend on how strong, and how the mounts and belts are positioned, it can only be for the good.....IMO of

course

I really hope that there are other builders/maufacturers local to you so that you can have a 'squizz' at their harness mounts

ATB Fozzie

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

|

|

Avoneer

|

| posted on 29/7/05 at 09:44 PM |

|

|

Cheers Snoopy and everyone else for all your inout so far...

I have gone forth as follows as I think this is the best wasy forward for me and my chassis.

The eyes now sit at the correct SVA height and are long enough to screw almost to the bottom of the threaded tubes they are in.

What I am now looking for is the best way to strengthen/reinforce what I have done.

Thanks.

Pat...

Rescued attachment 1.JPG

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 29/7/05 at 09:45 PM |

|

|

And another pic:

Rescued attachment 2.JPG

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 29/7/05 at 09:46 PM |

|

|

Please excuse the Hollyoaks babes calender in the background.

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Fozzie

|

| posted on 29/7/05 at 09:49 PM |

|

|

Snoopy, so very glad you 'joined' in here!

I have/had NO concerns regarding strength and quality with regard to the 'Book/locost' MK mounts with the early chassis. Just, as you have

read about height/positioning

So pleased you have addressed those issues with the new locost/book chassis that you are now producing!

Is Pat/Avoneer anywhere near you?

ATB Fozzie

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

Avoneer

|

| posted on 29/7/05 at 09:52 PM |

|

|

Hi Fozzie,

I'm not far from MK - Am I missing something?

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Fozzie

|

| posted on 29/7/05 at 10:03 PM |

|

|

Pat, I was just pondering as to whether Snoopy and co would let you visit so that you could see ...in the flesh so to speak. how the harness

mounts/bolts are fitted. Sometimes I think actually seeing something you know is right, makes everything all fall into place! how the harness

mounts/bolts are fitted. Sometimes I think actually seeing something you know is right, makes everything all fall into place!

I know sometimes that all of our opinions in words, can just make things...ahem....foggier....

I hope I am not being presumptious...

ATB Fozzie

ps talking of 'in the flesh', perhaps this weekend is/is not the one to go. IIRC I think they have young ladies visiting.....

'Racing is Life!...anything before or after is just waiting'....Steve McQueen

|

|

|

Avoneer

|

| posted on 29/7/05 at 10:09 PM |

|

|

Hi Fozzie,

I have been to MK on several occasions and helped a few people with their MK's.

I have also finished an Avon, and have several friends with various cars, Ginetta etc.

That's why I can't see a problem with just slugs welded to the back of the chassis tube.

If the lengthening of mine will only increase the twisting motion of the top tube, then this can easily be reinforced.

I only tack everything on my chassis and my friend (who build his own Avon chassis and has been welding and CADing structures for many years) has been

doing all my welding. I would put my life in his hands so to speak and he can't see a problem doing it the way it currently is, all be it with a

triangle gusset on the front side.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 29/7/05 at 11:18 PM |

|

|

Hi Snoopy.

Yep that's it - there will be a 1" sided triangle gusset made from 3mm plate (nicely guilotened by MK) exactly where you have drawn.

I think that will more than do the job and the only problem I can see is that in an impact, the top tube will twist - but that's what you want

isn't it if the impact is gonna be that bad.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 29/7/05 at 11:19 PM |

|

|

Snoopy - wha the hell was that all about

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

kb58

|

| posted on 30/7/05 at 12:51 AM |

|

|

quote:

Originally posted by Avoneer

Cheers Snoopy and everyone else for all your inout so far...

I have gone forth as follows as I think this is the best wasy forward for me and my chassis.

I agree we ultimately have to do what in our best judgement is right for us.

Having said that, once it's welded, how about a test to set your mind at ease. That is, figure a worst case deceleration during an accident of

10Gs. Your upper torso weighs, oh, say, 120lbs. Half that will be taken up by the lapbelt, so that leaves 60lbs. Your head, being above the mounts

will "weigh" more in an accident due to leverage, so say the total is now 70lbs. At 10Gs * 70 = 700lbs. Screw two bolts into the mounts

and loop a rope over it. Apply 700lbs in the forward direction.

Since you're betting your life it will be fine, nothing should happen when that force is applied...

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

Rorty

|

| posted on 30/7/05 at 01:15 AM |

|

|

Pat (Avoneer), I'm afraid you've gone and made matters even worse by your latest addition. Take a look at what you've done!

You've effectively increased the length of the lever which will make it easier for the harness to rotate that square tube and rip it out of the

chassis.

I see your diagonal (which actually sits too high up from the base plate) and there's plenty of room to weld a horizontal tube in there. If

necessary, cut a small fishmouth in it to clear the bottom of the diagonal.

I agree with FoZZie; if you can, go and look at MK's latest offering and talk to them about why they have adopted it.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

907

|

| posted on 30/7/05 at 07:50 AM |

|

|

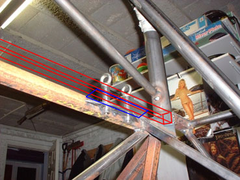

Hi All.

Personally, I'v never liked the idea of 4 belt mounts welded to a single cross member.

Welding them on the back face of the box section is not "good engineering practice".

How about an aditional cross member, (see pic, red lines) with the threaded bosses

welded into a plate between the two cross members, (blue lines).

This is how I'v made mine. When the top cover sheet goes on it's then covered up.

Just my 2 p's worth.

Paul G

Rescued attachment s-m-s.jpg

|

|

|

907

|

| posted on 30/7/05 at 08:45 AM |

|

|

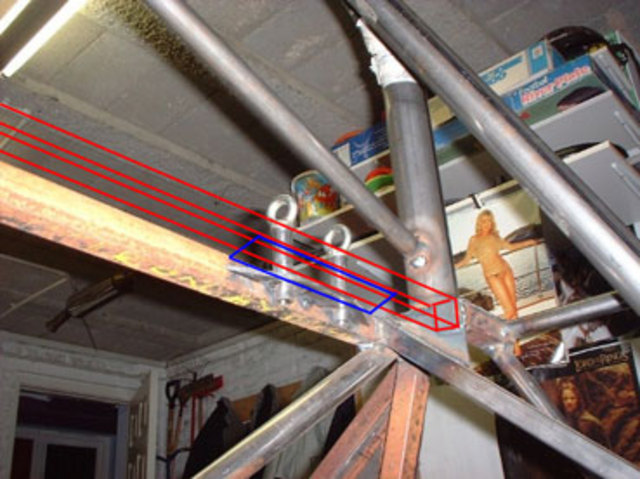

I'm back again.

Thought I'd better show you mine.

Rescued attachment top-s-b-mounts-s.jpg

|

|

|

Avoneer

|

| posted on 30/7/05 at 09:12 AM |

|

|

Hi,

Rorty - many thanks for your input and experience, but I just can't see how even approx 10G of force could rip out that top bar. The following

pic shows how it is fully welded at each end with a multitude of other bars and plates coming off it at various angles.

With all the Locosts/MK's etc, on the road with slugs on the back of this bar, why have I never seen or heard of any reports of them ripping out

or twisting, even in racing?

I know a horizontal bar in the cage would be best, but I don't like the look of them and don't want one - that surely isn't the

only solution?

I can't see how what I have now done has made it worse? Fully welded, the only problem I can still see would be the twisting force, but this can

be re-enforced by tying the top bar to the middle one can it not?

After SVA, they will be made level with the top of the tube and will be almost the same as MK's then - and I know of a few cars that have had a

shunt and had no twisting of ripping out of this bar.

I fully appreciate what you are all saying and many thanks for the on-going input.

Thanks,

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 30/7/05 at 09:12 AM |

|

|

Forgot the pic:

Rescued attachment bar.JPG

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 30/7/05 at 11:20 AM |

|

|

This is how Fisher do it on their race cars (and that's a lot different from how mine will be isn't it???):

Rescued attachment fuel_pump_01.jpg

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Rorty

|

| posted on 30/7/05 at 01:02 PM |

|

|

quote:

Originally posted by Avoneer

I fully appreciate what you are all saying...

With respect, I don't believe you do, but it's your car and only you can determine how it will be built.

907's set-up is the best non-roll bar method I've seen on a se7en (admittedly I've only taken an interest in this area since this

thread arose); it's a great solution to each and every point raised so far, and very well executed.

Really nice, professional looking work 907!

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Avoneer

|

| posted on 30/7/05 at 01:29 PM |

|

|

Thanks 907.

If the inserts are only welded to the plate, won't that be even worse as they will only be welded at one point on there circumference, where

mine would be welded like this and then up each side of each tube as well and at the front with the triangular gusset?

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 30/7/05 at 02:06 PM |

|

|

Rorty, please can you comment on the previous pic of a racing Fury and the following pic of the Stuart Taylor Phoenix with the chassis made by

caged. Thanks. Pat...

Rescued attachment st3.jpg

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

907

|

| posted on 30/7/05 at 02:06 PM |

|

|

Sorry Pat...... only trying to help.

If you don't like my method of counteracting the twisting force that

would be exerted on the box section cross member, then please, don't use it.

Lets face it, if you have a head on in a seven you'll probably end up under the other vehicle,

or in the event of an impact that could destroy the belt mounts, your kidneys

will be either side of your navel.

ATB Paul G

p.s. Thanks for the complement Rorty,

it's made me blush.

[Edited on 30/7/05 by 907]

|

|

|

Rorty

|

| posted on 30/7/05 at 02:42 PM |

|

|

Pat,

The threaded bosses on the Fury look to be welded quite securely to that square tube, but I don't get the web between them. To be of any

practical use, the web would be better if it were extended past each of the bosses. But I just wouldn't do it that way to begin with.

The Stuart Taylor Phoenix looks to me to be a right bodge! All the above IMHO; I'm sure the nice people at Stuart Taylor know what

they're doing.

Pat, there are a dozen or more ways to do this, and some dodgy examples of engineering abound (I wonder if any have been tested statically or

dynamically).

You will see many variations in cars from amateurs to commercial manufacturers, but their methods of attaching the shoulder straps to the chassis

aren't necessarily proven or the best solution. They're mostly there to meet SVA requirements and not much else.

I rode bikes for years (and rode motocross and trials) and I could have worn a cheap moulded Taiwanese helmet which met the basic safety requirements,

but I've seen what can happen to those helmets by just sliding off the roof of a car onto the ground! I wouldn't wear one of those

cheapies in a fit. I choose to look after my ugly noggin so I wore a quality hand laid glass/carbon helmet with a rating that far surpassed the

required rating. But, those damned plastic lids sell by the thousands. Go figure!

If you're happy with your harness attachments, then you go for it son!

We can only offer advice (not instructions); mine is based on years of witnessing hard impacts and roll overs on the track and some subsequent

injuries and retirements from motorsport.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Avoneer

|

| posted on 30/7/05 at 03:05 PM |

|

|

Thanks.

907 - I know you were trying to help, I was just wondering what other advantages your method had apart from the twisting aspect, which I could remedy

in mine.

Rorty - the ST chassis is the one made by Caged - the guys that know more about safety than most and build all the cages for Caterham etc.

Not trying to justify anything, but if Caged think it's ok that way (which is less than mine as they don't have the web on the back and

they are welding round to round) I think it should be fine - I'm sure Caged will have tested it and worked out if it was strong enough.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 30/7/05 at 03:57 PM |

|

|

907 - Just read the second paragraph of your point and that says it all...

If you're in a crash bad enough to rip the mounts off, I'm sure there will be far worse things to worry about.

Cheers,

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

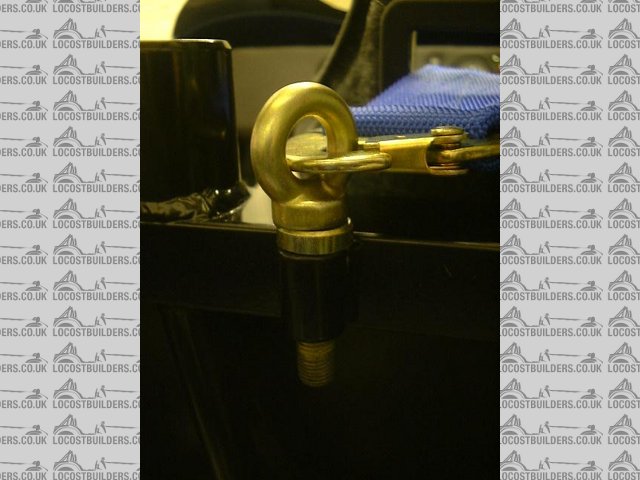

Avoneer

|

| posted on 30/7/05 at 04:48 PM |

|

|

And I suppose Westfield have got it all wrong to?

Rescued attachment 20020910_eyebolts_2.jpg

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|