Anman

|

| posted on 30/11/06 at 05:48 PM |

|

|

Car design

Hi,

I am very interested in building my own car. But I am even more interested in building one in designed myself. I am a student mechanical engineering

and have decent experience with soldisworks.

Because i dont have the time and money right now to build a car right now, i though i start designing a car of my own.

I started just copying the chassis from the book into Solidworks to get a feeling for the dimensions. But i was wondering why some design desicions

were made and why particular dimensions where chosen.

So i was wondering if you could help me with that. Maybe there is a site or a book with some basic concepts?

Also i was wondering what is the advantage of putting the engine in the rear instead of the front?

I hope you can help me.

Thanks in advance,

Anne

|

|

|

|

|

DIY Si

|

| posted on 30/11/06 at 05:57 PM |

|

|

Firstly, welcome to the mad house. Most of the design decision on the Book chassis are, I believe, pinched form the early Caterhams. Also the book

chassis is very easy to improve and the book has many "discrepancies" in it regarding tube lengths and sizes. I can't remember what

it's called but there are books on the basis of chassis design, try searching Amazon.

A rear, presumably you mean a mid engined car?, will have a relatively higher handling limit, but is harder to control past that limit, compared with

a front engined rwd car. It can also allow for a wider range of engine to choose from, as any front wheel drive set up can be thrown in the boot.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

flak monkey

|

| posted on 30/11/06 at 06:08 PM |

|

|

Welcome to the site

You will find a wealth of knowledge lurking on here, and plenty of sarcasm too.

Chassis design is not too tricky, follow some basic rules and you cant go too far wrong. The skill comes in optimising the rigidity to weight ratio.

Obviously the chassis needs to be designed around you, your chosen engine and other running gear.

The main problem with designing your own car from scratch is bodywork. There are several guys on here who will testify to how much work goes into

manufacturing your own bodywork (alanb and sgraber to name 2).

David

PS which uni are you at?

[Edited on 30/11/06 by flak monkey]

Sera

http://www.motosera.com

|

|

|

Jon Ison

|

| posted on 30/11/06 at 06:11 PM |

|

|

Hi n welcome........

Take a look in the "mid engined" section for some real inspiration on car and bodywork design.

|

|

|

Anman

|

| posted on 30/11/06 at 06:24 PM |

|

|

Thanks for your replies.

I did mean mid engined when i said rear engined. Btw i am not stuck on mid engined, just wanted to ask something about it. Thats why i posted my

questions in the general chassis thread.

My uni is located in the Netherlands, Universiteit Twente.

|

|

|

russbost

|

| posted on 30/11/06 at 08:00 PM |

|

|

Welcome to the looneybin, as already said there is much information on here along with theP***taking!

I'm a dyed in the wool mid-engine man myself (after all when was the last front engined F1 car, about 1961?) so you're thinking along the

right lines. Look back thro' some of the old stuff in the mid-engine section, I'm sure you'll find loads that's interesting.

I no longer run Furore Products or Furore Cars Ltd, but would still highly recommend them for Acewell dashes, projector headlights, dominator

headlights, indicators, mirrors etc, best prices in the UK! Take a look at http://www.furoreproducts.co.uk/ or find more parts on Ebay, user names

furoreltd & furoreproducts, discounts available for LCB users.

Don't forget Stainless Steel Braided brake hoses, made to your exact requirements in any of around 16 colours.

http://shop.ebay.co.uk/furoreproducts/m.html?_dmd=1&_ipg=50&_sop=12&_rdc=1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

suparuss

|

| posted on 30/11/06 at 09:31 PM |

|

|

mid engine is the only way! just kidding, both formats have their advantages and disadvantages. i think the main design criteria for the book chassis

was to fit it into the body shape and to use specific running gear. this is where most cars devolop from, especialy scratch built one offs like some

on this site, but from a chassis performance point of view it is best to design the body work to fit the chassis rather than the other way round.

the only way to efficiently design a one off scratch built car is have the main donor parts to hand for measuring so that the mounting points and

overall size can be drawn into your 3d design programme. from there it is just a case of connecting the dots with frame work in the strongest but

lightest way possible! easy! just remember triangles are good and tetrahedrons are better! id recomend a good book on chassis design and suspension

geometry which is very important.

cheers,

Russ.

[Edited on 30/11/06 by suparuss]

|

|

|

Anman

|

| posted on 30/11/06 at 10:21 PM |

|

|

Any suggestions for a good book on those subjects?

Isn't there a database somewhere with dimensions from existing engine(parts)?

|

|

|

iank

|

| posted on 1/12/06 at 02:33 AM |

|

|

For starters read this -> http://www.locost7.info/files/chassis/kitcaranalysis_V2.doc

It's a good start for zero money and gives a good flavour of the kinds of things you should be thinking about when putting a chassis together, I

think it was done by cymtriks who posts here.

Then get some balsa wood strips and glue and have a play around building chassis shapes twisting them and that will give you a really good feeling for

what works. If you can get the software, you can use computer packages to get real measurements if that interests you. But computers come a poor

second for getting an instinctive understanding of what is going on.

One very good tip IMO (which I think comes from Chapman himself) is to think of the chassis as a big bracket that joins up the important bits. i.e.

get the suspension design right, and the engine/people in the right place (for weight distribution) and only then designing the chassis is the right

way round. It's packaging the important bits that leads to a lot of the design decisions your wondering about.

The advantages of mid-engined include weight distribution, packaging, overall weight, parts availability and fashion  Unless you require 100%

perfection for competition either will do an excellent job for a road/trackday car. The 911 makes a good example of what can be done even with the

worst possible basic design. Unless you require 100%

perfection for competition either will do an excellent job for a road/trackday car. The 911 makes a good example of what can be done even with the

worst possible basic design.

There aren't many sources of accurate measurement of engines etc, but there is a scan of a dimensioned zetec drawing on here somewhere.

Hmm just found this http://www.locost7.info/files/engine/22R-2.jpg not sure how useful it would be though.

Here's a copy of the zetec drawing

http://www.locost7.info/files/engine/zetec1.jpg

[Edited on 1/12/06 by iank]

|

|

|

Anman

|

| posted on 1/12/06 at 06:39 PM |

|

|

Another question i have i regarding FEA calculations.

I was wondering which programs you guys use. I have a licensed version of Ansys 9, although i dont like that program. How do you model your chassis

and how do you measure important charaterisitics (eg where are the constraints and loads)?

thanks

|

|

|

nasty-bob

|

| posted on 1/12/06 at 11:15 PM |

|

|

Hi,

It's been mentioned, but there really is quite a bit of work to do before getting on to the chassis design.

You need to choose your suspension type and define the geometry. And most importantly (in terms of chassis design), decide where the dampers are to be

mounted.

Then get as many components as you can into CAD. As a minimum you will need engine, gearbox, suspension and a ergonom (driver). But the more parts you

put in the better the whole design will be refined and the better systems will work.

In terms of CAD, I use Catia for modelling but Solidworks is fine. For FEA, from my experience I-Deas is pretty user friendly. But without the

facility to benchmark results it should only be used for comparison between iterations, rather than as gospel (use a large safety factor). Use 1D

beam elements to construct the model and input forces into suspension pick up points and damper mounts. Torsional rigidity calculations will give you

an idea of whether your design is any good compared to other chassis' but you ought to focus on the suspension loads, load paths and max.

stresses.

Finally, remember that you want to build this one day. I've seen designs that are very pretty by are not manufacturable (within reason). Curved

tubes- yes they look nice but your design will no longer be a true spaceframe, and they are difficult to manufacture accurately and cheaply.

Oh....and thin walls, fat tubes are better than thick wall thin tubes- as you know, studying engineering.

All the best,

Rob

|

|

|

cymtriks

|

| posted on 1/12/06 at 11:38 PM |

|

|

quote:

Originally posted by Anman

Another question i have i regarding FEA calculations.

I was wondering which programs you guys use. I have a licensed version of Ansys 9, although i dont like that program. How do you model your chassis

and how do you measure important charaterisitics (eg where are the constraints and loads)?

thanks

I used Nastran.

I wrote the input deck manually, you don't need more than one beam element per length of tube and a hand written input file is much easier to

edit to check out variations.

I restrained the model vertically at the rear suspension spring mounts and applied a load up and down at the front suspension spring mounts. I also

held the chassis vertically and laterally at the front half way across the chassis. I used a single axial restraint at the rear.

I used the displacements at the front to calculate the stiffness.

The book chassis has about 1200ftlbs per degree. Adding some extra triangulation and removing tubes that don't do much increases the stiffness

to about 2700ftlbs for a weight of 10lbs less.

Regarding mid engines this is favoured due to the lower polar moment of inertia possible with this layout. That is what the text books say.

Some designers think that the real reason is to gain traction at the start of a race, by putting more mass over the rear wheels, and to permit the

driver to sit lower by not having a drive shaft going under his seat.

Regardless of which view is correct it does not improve everything. Moving any mass futher backwards will reduce aerodynamic stability and the

tendency to oversteer suddenly at the limits of cornering.

|

|

|

Anman

|

| posted on 3/12/06 at 02:15 PM |

|

|

Could you give me some more info about how you guys measure torional stiffness etc(pics maybe?). Because i was just messing around with a few very

simple test cases(eg a box) and am not sure where to place loads and constraints.

Thanks

|

|

|

nasty-bob

|

| posted on 3/12/06 at 09:43 PM |

|

|

Well, I'm sure different people have different methods, but if you simply want a figure for torsional stiffness it's fairly straight

forward.

Constrain the front top mounts using ball joints. Then apply a positive vertical force to one rear top mount and a negative vertical force to the

other of the same magnitude.

Knowing the forces applied and their distance from the chassis centreline, you know the torque. Measure the displacement where the force was applied

and use trig to work out the angle.

You will find that the stiffness of the chassis will vary depending on how much torque you apply but as long as you pick a reasonable force to input

you'll pretty close, if you know the proper suspension loads for your car even better.

FEA will give you a slightly higher than actual result as it assumes that everything is perfect.

Have fun.

|

|

|

Anman

|

| posted on 3/12/06 at 10:06 PM |

|

|

Ok, thanks i was thinking to complicated. What would be a realistic force to apply to the chassis (x times the car weight?)?

|

|

|

Fred W B

|

| posted on 4/12/06 at 11:18 AM |

|

|

Some sources say that the required torsional regidity (in fl/pd/deg) should be numerically twice the loaded (with driver) mass in lb, while others say

three times.

But you have to decide what you think you need/can live with.

Cheers

Fred W B

|

|

|

ettore bugatti

|

| posted on 4/12/06 at 07:06 PM |

|

|

Im using Autodesk Inventor 10 With Ansys integrated, very userfriendly.

[Edited on 4/12/06 by ettore bugatti]

|

|

|

force10

|

| posted on 4/12/06 at 09:36 PM |

|

|

We've cheated to a certain degree by using a very tried and tested chassis design in the locost and focusing on just developing a full body,

this should give lots of people a bit more choice when it comes to the styling of their finished car.

Maybe next year we will work on our own chassis, many of the dimensions will be determined by our choice of donor vehicle and how many components we

use from it.

I think mid engined is the way more and more kit companies will go simply due to the vast number and choice of transverse donors out there.

Good luck with your design, i hope you come up with something really refreshing and eye catching.

FT

|

|

|

Anman

|

posted on 4/12/06 at 09:49 PM posted on 4/12/06 at 09:49 PM |

|

|

I hope to that i can come up with some good designs. Got a lot of ideas in my head...

Only thing I really descided is that it is going to be a mid engined car.

|

|

|

Anman

|

| posted on 6/12/06 at 06:47 PM |

|

|

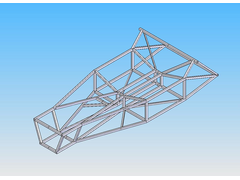

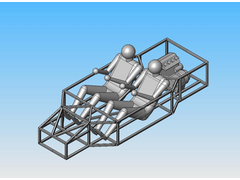

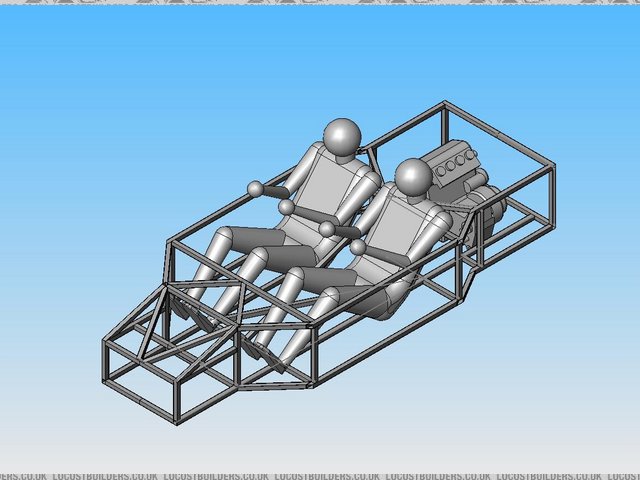

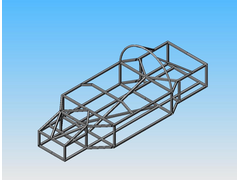

Ok I have been messing with Solidworks. The first picture is a picture of a front engined locost chassis which i abandoned but i would like your

opinions about it.

The second picture is a picture of a frame i am currently working on. It still needs some extra bracing and reving but this gives the basic idea. I

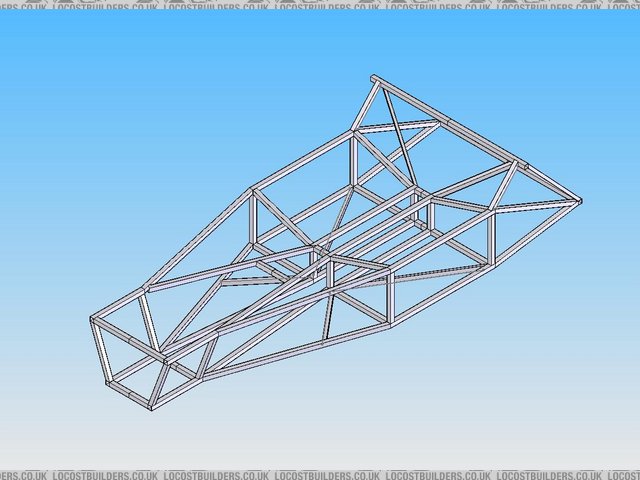

would like to know what you guys think.

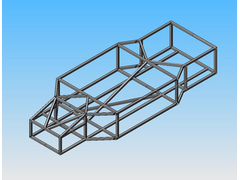

The third picture is a impression of how people and an engine would fit in this chassis, the used engine model is a bit small...

Rescued attachment frame2.jpg

|

|

|

Anman

|

| posted on 6/12/06 at 06:51 PM |

|

|

Picture 2:

Rescued attachment a.jpg

|

|

|

Anman

|

| posted on 6/12/06 at 06:51 PM |

|

|

Picture 3:

Rescued attachment test.jpg

|

|

|

Peteff

|

| posted on 6/12/06 at 06:54 PM |

|

|

Is it dual control?  It looks a bit short in the leg department It looks a bit short in the leg department

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Anman

|

posted on 6/12/06 at 07:23 PM posted on 6/12/06 at 07:23 PM |

|

|

It's not dual control, i only have one model for a driver, would be fun though...

You are right about the leg space, i need to find a few more cm to accomodate the legs.

|

|

|

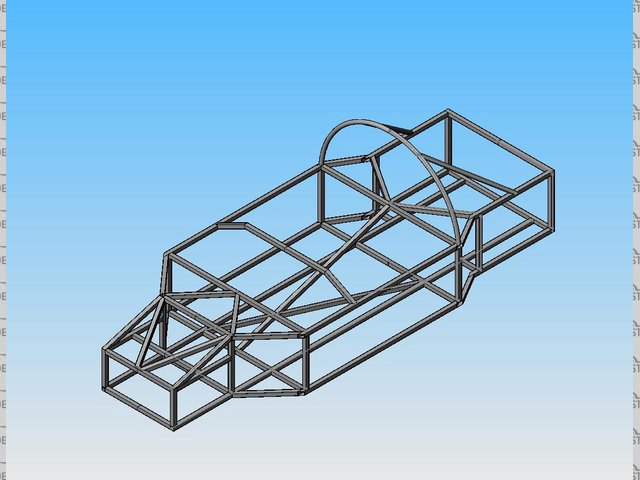

Anman

|

| posted on 7/12/06 at 06:44 PM |

|

|

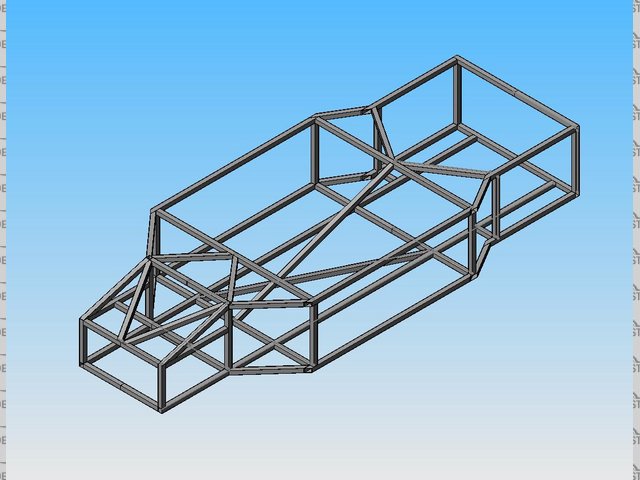

Another update, although there doesnt seem to be much interest in my efforts.

Increased the length and width to accomodate the passengers and added a rollbar.

Rescued attachment a2.jpg

|

|

|