image attached

[Edited on 8/11/03 by givemethebighammer]

Rescued attachment rollbar.JPG

I have been trying to make some roll bar stays but am having problems cutting the joint where the stay is welded to the roll bar. Would be easy with

square tube as you could just cut a semi circle out of two opposite sides the same radius as the roll bar. Round tube not so easy. Any tips ?

image attached

[Edited on 8/11/03 by givemethebighammer]

Rescued attachment rollbar.JPG

Havent done it yet, but I am using 2" tube so I will use a 2" hole saw. I can see no reason why it will not work

Just found this:

http://www.ihpva.org/people/tstrike/tubemiter.exe

those clever bike building people

input the tube dimensions and it draws you a printable template ...

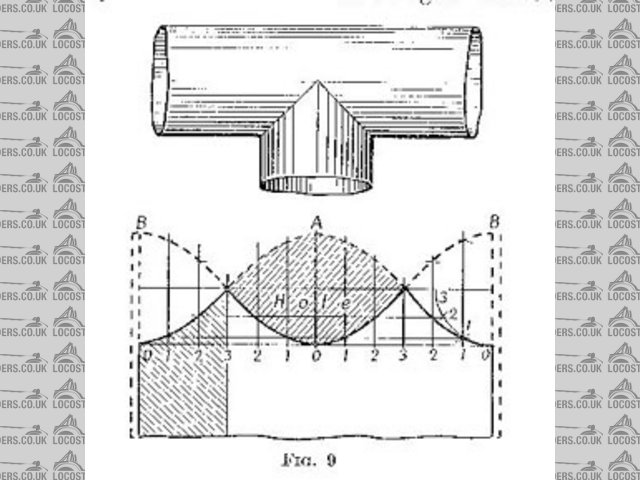

Hi Chaps,

The joining of two pipes to form a tee IMHO is less complicated if they are of different diameters, i.e. 2" roll bar, say 1 1/2" brace.

Then you just dish the end of the brace pipe to suit the radius of the roll bar with a grinder.

If you wish to join pipes of equal diameter you cut the end of the brace pipe at 45 deg, turn it over and cut at 45 deg again to form a 90 deg point.

The hole in the roll bar is two cuts at 45 deg half way through to form a vee. see diagram.

Personaly I think they look better with smaller braces.

The hole cutter idea would work in this case (small to large) saving shaping with the grinder.

Hope this helps.

Paul G

[Edited on 8/11/03 by type 907]

[Edited on 8/11/03 by type 907]

Sorry , forgot diagram.

Rescued attachment Lotus 021s.jpg

With the roll bar stays, it's called a fishmouth mitre as the shape of the .......... well you get it!

I did mine by trial and error, using the angle grinder, and was surprised by the shape I ended up with!

With a little patience it can be done.

BTW my main hoop was 2", the stays 1.75".

Alternatively use the above link and get a template.

Marcus

I've used the tubemiter.exe program before. it's good, if it's the same one. handles different size tubes and join angles.

quote:

Originally posted by Mark Allanson

Havent done it yet, but I am using 2" tube so I will use a 2" hole saw. I can see no reason why it will not work

Used tubemiter.exe and the old angle grinder - two perfect (well nearly) joints in about 10 mins. Shame my welding wasn't as neat. Guess

I'll just have to grind it back and sand a little before painting it

I didn't quite work out with the tubemitre thing if you were cutting into the roll bar tube, cos if so, it is a no, no. The hole saw idea is the best

didn't need to cut into the roll bar.

I think it is a quirk of the program that if the size of the tube you are mitering is greater than that you are connecting to the program produces a

weird "mirror" image template. I just used one half of this to cut my joints

[Edited on 10/11/03 by givemethebighammer]

I dont think it's a quirk....it makes sense to me....surely you wouldn't want to be fismouthing a tube that was bigger than the one it mated

with?.....you would have gaps at each side...

I think common sense says that if you have different diameter tubes that the notch will be on the smaller one?...I.E the bigger tube is the continous

one and the other joins to it....