So, any comments or observations would be gratefully recieved (well, probably

).

). Kingr

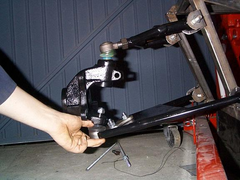

Put my front suspension on the car for the first time last night, and I'm pretty pleased with how it looks. The top and bottom wishbones are my

own design - the bottom is modified to accept an Astra mk2 ball joint, and the top is modified to give 6 degrees of castor with the brackets fairly

central on the tubes. I used the design that I have rather than as shown in the book to allow more room for the shock.

So, any comments or observations would be gratefully recieved (well, probably  ).

).

Kingr

pic 1

Rescued attachment front suspension 3_small.jpg

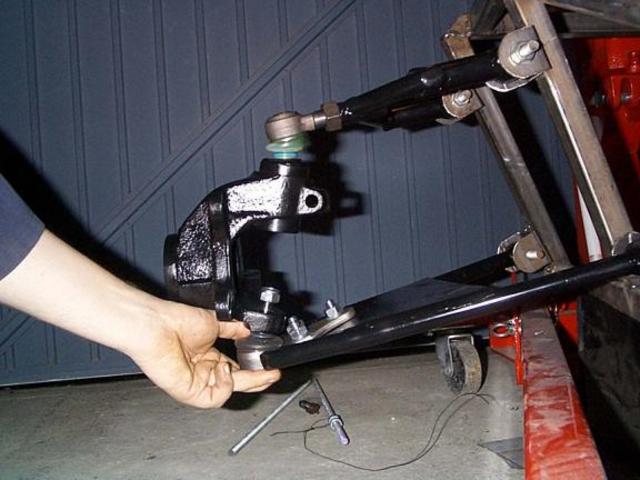

full compression

Rescued attachment full compression 1_small.jpg

full droop

Rescued attachment full droop 1_small.jpg

Just one question

on the bottom wishbone have you got a link between either side to assist in torsional loading or are you just using the ball joint mounting plate to

hold them

apart from that question looks good m8

Yes, just using the mounting plates - although I haven't done any analysis on it, I've got no reason to think that it would be any weaker

than the book design, infact, it should be significantly stronger - the book tells you to crush the tubes, mine are left uncrushed and mount the ball

joint in between. You may not be able to see from the photo, but the ball joint mount is angled so it is positioned going from the bottom to the top

of the tubes (sorry, I know I'm not being very clear but it's quite hard to explain). Surfice to say it certainly wasn't the easiest

shape in the world to chop out of 3mm plate steel!

There are more photos in my album, so have a look there if like.

Kingr

nicely painted etc but where are you going to mount the shock???

The only concern I would have is that the Astra used McPherson struts, so the balljoint was never designed to take the kind of loadings it will get in this situation. There was a problem with these fracturing (or was it Cavs?) a few years ago when garages were jacking up the cars using the lower suspension arm.

It was the track control arm itself that used to crack, they used to do it all by themselves without the help of a clumsy jack. The were made from two

pressings spot welded together back to back and used to chatter together and fatigue crack. We used to change them for the modified ones as a matter

of course if even the slightest risk that the arm was damaged in an accident, the insurance companies did not wantthe risk of a recently repaired car

having an accident due to failure and the subsequent litigation. I never came across a balljoint failing, even if the wheel had been torn off.

If you are the slightest bit worried, keep checking for play, I am sure they would wear before failing

Mark

Just make sure that the bolts securing the bottom balljoint are of the highest grade you can get. 10.9's minimum with 12.9 strongly recommended

and torque them up according to the recommended torque for the the size and grade.

They look good though.

Cheers,

Craig.

Thanks for all your comments, I'll reply in order :

Viper - Yup, I noticed that too, just after I'd painted them (doh!), so I'll have to strip and area around where the brackets will be

mounted, mount the bracket and hope the heat doesn't knacker the rest of the paint too much.

Mark and Mike - Thanks for the warning and explaination - I would have checked them periodically anyway, but it's nice to know it wasn't

that part that failed!

Craig - The bolts currently holding them on are 8.8s but I've got some 10.somethings that came with them, so I'll use them once they being

put on permanently.

Kingr

One more question - what size hole do I need in the bracket for the shock?

Kingr

depends on the shocks you are gonna buy.

mine are 10mm....

atb

steve

I think the GTS shocks are 1/2 inch and these are the ones I'm planning to buy.

Cheers,

Craig.

Kingr- great photos of your suspension- is the upright from an Astra as well?

If so, did you have to do a lot of work to it to accept the balljoint of the upper wishbone. The reason Im asking is that i got a couple of Audi

struts but they are one piece and will require a bit of work to accept the top balljoint.

Thx for any help

chris

Is it my imagination, or does your set-up change from neg camber in bump to a large amount of pos camber in droop?

If so, what happens to the outside wheel in roll, and what are the track variances involved?

Hi Rorty + 8smokingbarrels,

Thanks for the comments,

8Smokingbarrels - The uprights are from a sierra, and the adaptors are from loloquality I don't know whether they would fit an audi though, other

people have made their own adapter though - cutting down the old mcpherson strut and welding a taper into that is one way.

Rorty - The suspension movement you can see is pretty big, a lot bigger than it's ever going to be on the car also I think the photos are a bit

deceptive, it looks like a lot more movement than there is. As I'm sure you're aware, going from one extreme to another is going to produce

massive camber changes compared to those in the comparatively small actual working area. The design of the suspension is barely different from the

book, the only difference being in the positioning of the top ball joint which is slightly further back due to design of the upright. I worked out the

difference in camber change before hand, and it was tiny IIRC, I'll work it out again, just to be sure though. A shorter top wishbone will result

in greater negative camber during compression, which is unlikely to result in disaster. Thanks for the interest though.

kingr

Sorry, just to clarify, the top ball joint on a sierra hub is slightly further away from the wheel. "back" isn't much of a description

at all. The lolo adaptors have an angled taper to put the ball joint slightly further towards the wheel than they might otherwise be.

Kingr