Tube "R"

macbrew - 19/5/03 at 07:28 PM

Just dropped in my 1300 X Flow and found that tube "R" (fitted as book measurements) was touching the fuel pump so I had to move it. Just

another little mistake Ron.

craig1410 - 19/5/03 at 08:33 PM

Hi,

I have a related, if not identical issue which hopefully someone can help me with.

I'm fitting a Rover V8 in my book +4" wider chassis. Tube 'R' is going to go right through some fairly important parts of my

engine so I either have to remove one of my cylinder heads or remove tube 'R'. Is there an alternative route which this tube can take and

how much of a problem would it give me if I didn't fit it at all?

I was thinking of moving the forward end of 'R' backwards along tube 'J2' and then fitting another one on the other side

symmetrically to add the lost stiffness.

Any thoughts? Cymtriks, what do you think?

Cheers,

Craig.

Simon - 20/5/03 at 08:41 AM

Craig,

I've stuck a doodle in the photos archive called "R replacement" (red lines!!).

This is what Luego do on the Viento, and was suggested to me.

Hope this helps.

ATB

Simon

James - 20/5/03 at 10:04 AM

quote:

Originally posted by Simon

Craig,

I've stuck a doodle in the photos archive called "R replacement" (red lines!!).

This is what Luego do on the Viento, and was suggested to me.

Hope this helps.

ATB

Simon

That's pretty much what I'll be doing once the engine is in place. Although the closer to rails 'S' and 'T' that you can

get the R rails the better I'd have thought.

Cymtrics' plans also suggest putting in a second 'R' tube.

HTH,

James

Chris Leonard - 20/5/03 at 12:46 PM

The engine should sit slightly left of centre 19mm if I remember correctly this gives just enough clearance for the fuel pump and helps the angle of

the propshaft

Lars - 20/5/03 at 03:53 PM

i thought the angle of the propshaft is created by having the diff in the axle slightly off centre, so the engine can sit central.

craig1410 - 20/5/03 at 11:06 PM

Thanks Simon and James.

Simon, your doodle is exactly what I was intending. I also plan to carry out some mods along the lines of what Cymtriks has recommended, especially

for the triangulation within the LA,LB,LC,LD assembly. I may also double up J1 and J2 horizontally between FU1/2 and the corner braces in your doodle

Simon. This was part of some suggestions made by Syd Bridge and it should (in my mind) help to make up for the fact that the small corner braces

between Q and J1/2 don't go as far forward as they would if the book plans were followed (ie. Tube R fitted)

I agree with you James though and don't plan to change too much until the engine is in final resting position...

Cheers,

Craig.

craig1410 - 20/5/03 at 11:10 PM

Just a thought on the subject of propshaft angle:

Simon, did you mount your Sierra diff along the chassis center and did you also mount the gearbox output shaft along chassis center? This is what I

have planned although I am aware of the issue of having some misalignment to stop the needle bearings wearing out too fast. My theory is that since

the gearbox output flange and the diff flange are at different heights then that should do the trick.

Am I right? It's not too late since my gearbox/engine is not fixed yet.

Cheers,

Craig.

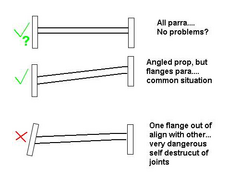

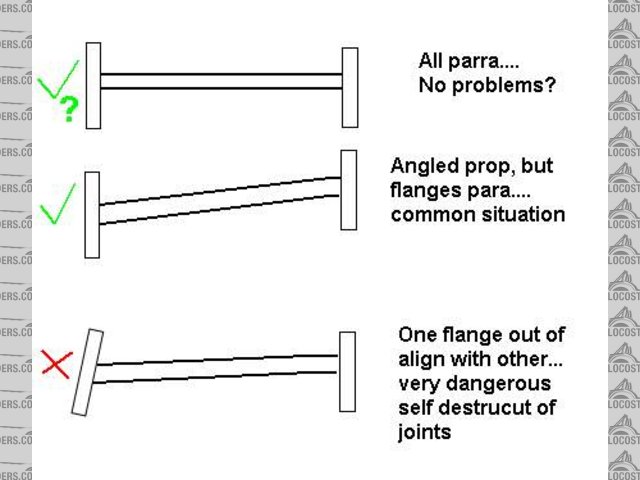

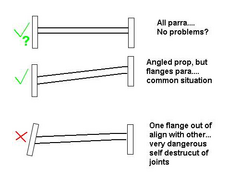

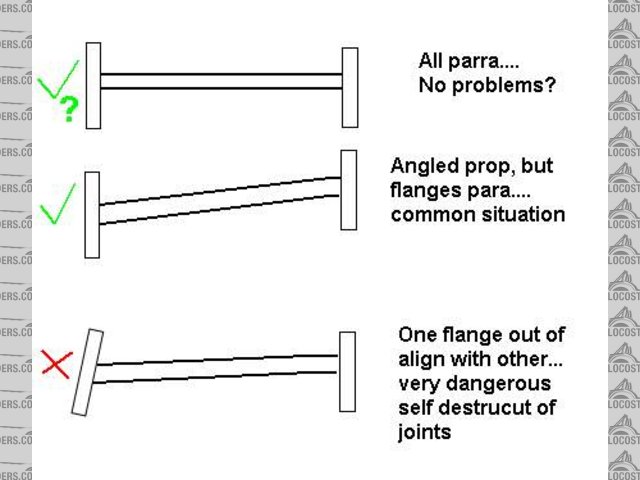

MikeP - 21/5/03 at 01:12 AM

You might want to double check the recommendations for aligning the gearbox and propshaft outputs. I'm pretty sure the issue isn't how they

align left/right or up/down, that's not a big deal within reason. I believe it's that you set them up to be parallel and then adjust one or

the other by 3 degrees to allow for even needle wear.

I've also read that it doesn't really make any difference and you should just set them parallel - the experts don't agree.

HTH

stephen_gusterson - 21/5/03 at 09:05 AM

This 'offset' thing has come up a couple times, and it got me worried. I have thought it through, and can see no vital reason for an

'offet' to HAVE TO BE included.

But then im not a motor engineer and I hope someone can shed more light.

If you look ar most diffs, be it IRS like a sierra or beam / live like a cortina, the diff IS offset and the driveshafts are unequal length.

Reason? The crown wheel takes the drive into the diff, which then has the 'sun and planet' or whatever they are called, gears to one side.

So, the input shaft is either gonna be central, with unequal shafts due to gears on one side of crownwheel, or the input shaft is a bit to one side

with the shafts equal length.

One think I have learnt that MUST be avoided is the gearbox and or diff flanges being out of paralell (sp?).

UJ 'spider' joints are not 'constant velocity' - they cant take the acelleration an slowing down created internally in the bearing

as the joint acellerates and dips into anglular movements of the prop / spider / flange.

any comments at to why an 'angle' is considered desirable, and that all in line - which seesm eutopian, is wrong....

atb

steve

Rescued attachment diff1.jpg

Simon - 21/5/03 at 11:20 AM

In order

Chris,

Craig and I are both building our cars "book + 4" wide" and using Rover V8 and (me) IRS and (Craig) de Dion, so quite a lot of what RC

did is irrelevant. Mech fuel pump on R V8 is on the nearside. Just got an SD1 cover, so that is actually blanked already (use electric pump). However,

other items do get in the way - oil pump/steering column (going remote).

However, I have mounted engine 1" to nearside to try and miss above.

Lars/Craig

The (Sierra) diff is mounted with the diff input on the chassis centreline. One side of the diff is wider than the other, to which the shorter of the

drive shafts is attached - though I'm sure you knew this already.

This gearbox output is also on the chassis centreline.

This may or may not be the attidude, but I'm not going to get excited about 1" misalignment over the length of engine/box (60" ?) About

1.7%

I do believe that on the vertical measurement, I have about 5mm diff - but that can be corrected with a spacer on g/box mounting - though not too

worried about that either.

Hope this helps chaps

ATB

Simon

PS Craig- sending you an email!!

PPS Wish I'd waited now - cos I want a Chevy powered Viento:-(

stephen_gusterson - 21/5/03 at 11:27 AM

Simon

on a live axle it bounces up and down a few degrees anyway.......

atb

steve

ps

your engine being 1 inch out of line is in line with the 'desirable not to be in line' urban myth (?or not)

craig1410 - 21/5/03 at 12:00 PM

Simon,

I may still run into problems with clearance on the engine but for now my engine is on the centreline and in line with the centreline throughout its

length. My diff is also on the centreline and yes I know about the unequal length shafts thanks...

I agree with what Steve is saying about the UJ's not being of the CV variety and I think that it is indeed very important that the input and

output flanges of diff and g/box are in the same plane as exactly as possible or vibration will result. I don't know if 1 inch in 60 is accurate

enough or not but I hope to get it as accurate as I can manage by bolting a straight edge to each flange and making them parallel at the tips of the

straight edge.

It might be worthwhile talking to Mike from Autoprop and asking him how much misalignment is permissible. I've not actually fitted my engine yet

so I can change strategy a bit if necessary. From what you are saying about clearance my Wife might be about to lose some legroom from her

footwell...

Cheers,

Craig.

Simon - 21/5/03 at 01:31 PM

Craig,

I got an SD1 front cover and fitted it yesterday.

There is very little clearance at the front of the engine, to the extent that I can only get the front pulley on one way round (ie about 1.5" ,

so make sure you get engine as far back as poss!!

,

so make sure you get engine as far back as poss!!

Also - got my radiator (from Eurocarparts - ordered 3.30pm Tue - arrived 3.30pm Wed - amazing) - nice fit behind my widened nosecone!!

ATB

Simon

stephen_gusterson - 21/5/03 at 03:08 PM

does that tight fit not make it a bit hard to pull the engine out from the box - can you get it out with the box attatched?

atb

steve

Simon - 21/5/03 at 03:45 PM

Steve,

Whole lot comes out in one go - though haven't tried with the SD1 cover (only with RR cover.

Will find out this weekend as while fitting clutch slave last w/e all bits fell out!!!

I am hoping (optimist) to have a go at starting engine, possibly, on Monday.

No silencers yet, so won't be running for long!

ATB

Simon

craig1410 - 21/5/03 at 11:23 PM

Simon,

What is the difference between the RR cover and the SD1 one? Which do you recommend I should use?

Cheers,

Craig.

Simon - 22/5/03 at 08:40 AM

Craig,

I lifted this from the relevant Rimmer page:

"Timing Cover Identification - Up to 1994

There are 2 main types of timing cover, fitted up to late 1994:

1. Saloon/sports, as fitted to Rover saloons and Triumph TR8s.

2. 4 x 4, as fitted to Range Rovers and Land Rovers.

The saloon/sports version has a more compact water pump, mounted lower down for improved bonnet clearance. The 4x4 version has a water pump mounted

higher up. In addition, the 4x4 timing cover usually has a mud shield to protect the front crank oil seal. Both types will fit all versions of the

engine (providing suitable ancillaries are available) and both types are further categorised as follows:-

The timing cover fitted to early vehicles (prior to 1976) incorporates an oil pump gear-housing designed for the early, 'short' oil pump

gears. Later timing covers have a deeper gear-housing, accommodating the longer pump gears used from the SD1 (1976) until the introduction of the

crank-driven oil pump (late 1994 on). Although the two types of timing cover are interchangeable, the oil pump hears and distributor would also need

to be changed.

If, however, uprating the early (pre 1976) oil pump is your intention, purchase Oil Pump Kit RB7480, which contains a spacer and longer gears, along

with the correct distributor drive, designed specifically for the early timing cover. (RB7480 is not suitable for later timing covers, 1976

onwards)."

Swapping ancilliaries includes crank pulley etc

I'm waiting for a book by David Hardcastle called "The Rover V8 Engine" - not the tuning version (already have that) - should explain

all interchangeability options and the Haynes SD1 manual.

I have a RR crank pulley, and an SD1 water pump pulley so will need to make a spacer about an inch thick.

Need to think about "fan" belt route too.

I'll put some picks up over the next few days

As to which I recommend - give me a while to think about/sort it out!!!

ATB

Simon

craig1410 - 22/5/03 at 08:51 AM

Thanks Simon, will do.

BTW, would you recommend the David Hardcastle books?

Also, I have a scruffy copy of the Rover SD1 workshop manual so let me know if you need any bits scanned in and emailed to you. It's good in some

respects but poor in others but it might help in some cases where a different perspective to the Haynes manual is required.

Cheers,

Craig.

Rob Lane - 22/5/03 at 08:58 AM

The 1300 xflow will just touch it. Why not remove mechanical pump, blank it off and fit an electrical one, much simpler.

The mechanical one is not known for it's reliability.

Rob Lane

Simon - 22/5/03 at 09:37 AM

Craig,

Thanks for offer - may well take you up on it some time, as I'm hoping to get myself an SD1 Vitesse towards the end of the year:-) (Rolling

resto, assuming Locost done!?!?!?)

Hardcastles "Tuning the Rover V8" seems quite comprehensive, but is now quite dated, talking of the "forthcoming 3.9" and rumours

of a 4.2 etc etc. Also, IIRC, all photo's are B&W - bit dissappointing for 17? quid.

If you can get a cheap 2nd h copy - might be worth it.

As for the other - still waiting for it to arrive, so will let you know.

ATB

Simon

elewayne - 22/5/03 at 04:36 PM

At the very first of this string Macbrew wrote that Tube R got in the way of his engine fit. "just another mistake Ron"

I'd just like to defend Ron and the book for a second.

( not that either need my defence)

The book makes no claims that it dosn't live up to, in my openion.

It dosn't claim to be an instruction manual.

Only a guide line for building your own version of a Seven.

It is also very diffacult to get a book like this published with out any mistakes. Most arn't that hard to find or deal with.

You have to use your own common sence

when following the text.

Looks like you might have guessed that tube R might have to be installed after the engine to avoid problems.

Stop crying, get back to work, reroute tube R to somewhere else and get on with your car.

Good luck in the future!!

macbrew - 22/5/03 at 07:45 PM

Not cryin just commenting.

The book clearly states that the measurements given are for 1300 x flow. It does not say anything about fitting tube R later. As I read it the idea is

to get the chassis completely finished and painted before bolting on the rest (which we all know is impossible). If you followed the book measurements

for the rear axle mountings the axle wouldn't move at all, and that would have pi$$ed me off.

I dread to think what the first edition was like.

Any body out there actually built one for £250 ? It's clearly a joke! I,m on a shoestring budget so far pushing £700 and it's not even on

it's wheels yet.

What was the question again?

craig1410 - 22/5/03 at 08:15 PM

Macbrew,

You didn't seriously think you could build a car for £250 did you? Didn't you do any research on the subject first?

I'm also on a budget and I still reckon that £2000 will be hard enough to meet and 12-18 months build time even harder but those are my targets.

It'll cost over £250 for the 4 coils and shock absorbers alone!

Uncle Ron may have made a few booboo's in the book but I've made even more just trying to follow his plans, even the bits with no errors!

I can't imagine how many errors I would have made if I'd been designing the car as I went along from scratch...

I must say that I had no intention to fit Tube R until the engine was in no matter what the book says and I didn't even fit tubes G1 and G2 until

I had a transmission and engine block to measure against. The trannie tunnel was the same although I am using a Rover V8 and not a 1300 xflow so I had

a few more issues I guess.

I agree that the book should be taken at face value and used as a guide only. If you are going to complete the build, in my opinion you need to change

your mindset to that of a sculptor and just keep smiling as you chip away the rough edges. If you let little things like the errors in the book get to

you at this early stage then you are very unlikely to finish the build. If money is a problem then be prepared to extend the build time because if you

can't afford to buy something off the shelf then you have to wait for it to become available through the 2nd hand market which always takes much

longer.

Try to enjoy yourself and remain positive!

HTH,

Craig.

craig1410 - 22/5/03 at 08:21 PM

By the way I see from your profile that you are using Sierra hubs with the book chassis. If this is front Sierra hubs are you aware of the issues with

using these with 'book' wishbones? You need mcpherson strut adapters and you need to modify the lower balljoint taper to suit the Cortina

balljoint. You also need different length upper(shorter) or lower(longer) arms to compensate for the different hub top arm length which would

otherwise result in huge amounts of positive static camber.

If you can then go for Cortina front hubs as per book. You might have to wait for some to become available but they can be had if you look. I got some

from a fellow LB forum member for £45 in good condition which I'd say is about the going rate. You can get them cheaper from the stock car racers

and at autojumbles.

Good luck!

Craig.

cymtriks - 22/5/03 at 08:24 PM

Tube R is the only diagonal across the top of the engine bay and is important to the chassis stiffness.

Using two short R tubes as described earlier in this thread reduces stiffness from about 1200 to 900 ftlbs for the book chassis and 2500 to 1950 ftlbs

for my modified chassis.

A better solution for wide engines may be to replace the top side tubes from the footwell ends to the chassis front by ladder frame sized tubes of 4x2

with 14g (2mm) wall. These tubes should be fully welded into the footwell ends which should also be in 14g welded in sheet. Replace the two short tube

Rs with boxed in 14g sheet braces making, roughly, a 45 degree triangle, four inches deep, across the width of the footwell ends.

It is heavier and more difficult to make but the chassis stiffness should be good and the V8 will easily compensate for the extra metal.

craig1410 - 22/5/03 at 08:32 PM

Cymtriks,

I wondered when you would come to the rescue

Unfortunately you've not given me the answer I was hoping for (ie. a simple one)

Well I suppose you have and you haven't really, I just wish I'd asked the question before I built the front of my chassis!

Should the 4x2 be oriented long edge vertical or horizontal?

By the way, what sort of stiffness would something like a Mazda MX-5 or MGF or Z3 have to put things in perspective? I know the Elise is in a

different class altogether so I'm not going to try to match that (7000lbs or something I think?)

Thanks,

Craig.

elewayne - 23/5/03 at 12:41 AM

That 250 pounds thing was clearly one of the several misprints, it was supposed to read 2500 pounds, I think.

I was tring for $5000 US. I almost have a roller at this point and I added up my spread sheet the other day and found myself at $4600 already.

Looks like it might hit $10,000 before I'm through. Why did I start this anyway.

macbrew - 23/5/03 at 07:58 PM

One small comment certainly gets the discussion going. No offence to anyone just lively banter.

Thanks for the advice craig but it all got sorted a few months ago .. MK hub adapters and longer bottom wishbones.

Don't lose any sleep about my finances, the shoestring budget is a goal not a restriction I'm just trying to see what it can be done for.

Target is £1500. It will be a slow build because I'm making (rather than buying) everything I possibly can with limited tooling. My comment about

the book title is that it's 20 year old and the second edition should have taken into account inflation and the un-availablkity of MK2 Escorts

rather than misleading people.

Yes I did research this project, my point is that it is impossible to do research to find out the real cost without first buying the book .... Catch

22. If you go ahead fine, if you dont £18 down the drain.

Good luck with your build .. sounds like a beast, wish I had the balls.

Alan B - 23/5/03 at 09:03 PM

Where do you get 20 years from..?

The first edition was published in 1996...

(I doubt the 250 was realistic then)

Or am I missing something?

stephen_gusterson - 23/5/03 at 09:50 PM

I have edition one.

it was first published in 1996.

Most people dont read and understand the trick in the wording

its called :

Build your own sports car for AS LITTLE AS 250 pounds.

you could say 200 or 20 or any number you wanted.......its all bollox anyway.

bit like writing a book called travel the world for 250 quid. Its easier if you have big tits, and in Rons case, the 'im a schoolteacher and

author - can you help with free stuff' approach

atb

steve

macbrew - 24/5/03 at 05:53 PM

Must admit I had no idea when the first edition was published, I guess it was written a few years before. Some of the pictures in the book look like

they came from the 60's.

I said 20 yrs cos that's when the last MK2 came of the line ... approx. my doner was a "W" one of the last I think.

Keep it comin I'm ard as butter.

kiwirex - 25/5/03 at 08:25 AM

A salute to cymtriks, wizard of structural analysis.

I was looking at the Luego web site the other day and some pics of the Viento. It looks like it has dual diagonals on the side of the engine bay.

I.e. TR2 from bottom of H to top of FU2 (as in the book), but looks like one from TOP of H to bottom of FU2.

My limited ability to visualise (and total lack of 3d software) hints that they might not intersect.

I think (from a hazy memory of a post from Luego themselves) they're using 2x1 for the diagonals.

If you've got a minute - and it's not stepping on Luego's toes - what effect would that have on the rigidity of the chassis?

Thanks,

Greg H

cymtriks - 27/5/03 at 10:29 AM

It took a while to find that picture on the Luego site!

Two tubes in an X will increase the stiffness of the front. I have been updating my model of the lowcost to include the rear luggage area and to get

better esults for the flex in the rear suspension mounts. The results so far suggest that the luggage area adds what the mount flex takes away.

I'll put in an extra tube TR to see what it does to the standard chassis as this is an easy mod to make to my analysis.

The Luego site states that their chassis was FE stresses by Cranfield Institute of Technology and the model checked against a real chassis before

conducting a series of modifications to improve the design. Exactly the right way to do it.

However there is no indication as to what changes this actually led to. There does seem to be a different standard for every chassis on their site and

the changes outlined in my mods don't seem to appear in any of them. The thicker tunnel tubes suggest an attempt to take the weight of the chevy

V8 rear end/gearbox mount. The X arrangement of the extra TR1&2 tubes will certainly help

If I was fitting a big engine I'd use my mods plus:-

1) an extra vertical half way down the engine bay side, in line with the engine mounts and run a tube from top of tube H to the bottom of the new tube

and from top of tube FU to the bottom of the new tube.

2) 2x1 inch tubes G1/2, C, E and F1/2 with the 2 inch side vertical. The G1/2 tubes will need to pass behind the lower wishbone mounts near tubes

FU1/2 befor joining the sides of tube E

3) weld in the footwell ends in 16g or 14g sheet.

4) extra diagonals from where P meets tubes n and o to the bottom of tubes H and the tunnel arch over tube B2.

5) beef up tube J1/2 down the engine bay sides by replacing them with 4x2 as peviously described or short R tubes (not as good) or short R tubes plus

increased width J tubes (2 inches wide or more).

Really big V8s may be better suited to a ladder frame, hot rod style chassis of 4x2 RHS in 14g or (thicker) 1/8 inch wall. Properly X braced and with

a decent tunnel, seat back and scuttle structure this could give a stiff structure only slightly heavier than the book frame and with a completely

open engine bay area for a big and wide engine.

kiwirex - 27/5/03 at 10:07 PM

Thanks for that Cymtriks

I'd like to do a small v8 (if I can find one for my money), so I'll look at doing what you suggest.

Appreciate it.

- Greg H

,

so make sure you get engine as far back as poss!!

,

so make sure you get engine as far back as poss!!