I have learned the hard way.... double the work

I know this has been visited a couple of time on here and have read all articles but am now confused.

Does the centerline of the top front wishbone line up with centerline of bottom wishbone like at http://www.designdraughting.pwp.blueyonder.co.uk who

also have a nice friendly jig to line up brackets before welding.

OR!

Is there a 5 degree 30 minute angle between them like discussed previously and described at http://locostbuild.tripod.com/

If there is a 5 degree 30 minute angle and the front top bracket is overhanging on LA and LB can I put a panel between LA and FU1 and mount brackets

on that and equivalent on the other side?

[Edited on 22/4/03 by Gremlin]

[Edited on 22/4/03 by Gremlin]

Gremlin, the ball joints/rodends at the outer ends of the wishbones should not lie in the same vertical plane. In other words, the top one should not

be directly above the bottom one.

The top one should lie to the rear of the bottom one, by somewhere in the region of 5 degrees.

quote:I don't understand what you mean, but I would recommend keeping it simple. Just attach the upper wishbones to LA/FU2 and LB/FU1 as in the book.

If there is a 5 degree 30 minute angle and the front top bracket is overhanging on LA and LB can I put a panel between LA and FU1 and mount brackets on that and equivalent on the other side?

Must disagree Rorty, LA and LB are wrong in the book. They need to lie back another 25.4mm to give the desired 5.3 degrees.

I have learned the hard way.... double the work

The upper balljoint (Transit) needs to be 20mm behind the lower balljoint (Cortina or Maxi) when viewed from directly above. Following the misleading

Book instructions for fabricating the top wishbone will reduce this to only 10mm, giving you only half the 5-and-a-half degrees caster that you

need.

I've had a look at Dougie's jig - the first link Gremlin posted - and it places the inner wishbone ends symmetrically. If you then make a

correct upper wishbone you'll get the caster required.

Hope this makes sense - I don't seem to be very at expressing myself this morning. Need more coffee!

Eddy

I agree the jig will give you correct castor, but if you build the chassis as per the book, the brackets will be hanging off LA and LB

So.. you have been warned.

[Edited on 23/4/03 by Hornet]

So let me get this right the jig will work if i go with book wishbones?

If i lean la/lb back 25mm at the top i assume the top l bar has to be moved back 25mm. Does this cause any problems later on in engine fitting or nose

cone/radiator fitting?

You are correct m8.... check earlier topics on this, it has all been cover before.

I havent fitted nose cone yet so cant answer that question.

But, safer steering is more important

When i looked at the jig it was used both sides and had all bottom and top brakets lined up on a central plane and thought that was wrong? How does the wishbone produce a 5 Degree angle?

quote:

Originally posted by Gremlin

When i looked at the jig it was used both sides and had all bottom and top brakets lined up on a central plane and thought that was wrong? How does the wishbone produce a 5 Degree angle?

Shoulda used Sierra uprights.

Then you could have used a concentric top mount that allows camber and castor changes.

Sorry, just had to get that in!!

But others correct. Top w/bone assymetrical so should (but doesn't) give you the 5deg of castor .

ATB

Simon

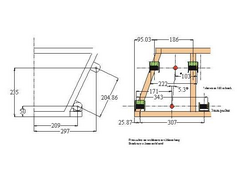

I see so the 4 mounting brackets are symmetrically placed on the chassis either side of the center line but the book upper wishbone needs to be

modified to drop back another 10mm to give an overall 20mm on the top ball.

So the attached picture of mounting brackets is wrong. The top front bracket should be inset the same from the bottom front bracket as the top inner

is from the bottom inner?

I do have a couple of sierra uprights how easy is it to use those instead simon?

[Edited on 23/4/03 by Gremlin]

Rescued attachment 0601c080.jpg

Hornet:

quote:

Must disagree Rorty, LA and LB are wrong in the book. They need to lie back another 25.4mm to give the desired 5.3 degrees.

Agreed Rorty. Your point is valid.

However, Gremlin... 3 points.

Point 1. The top wishbone dimensions in the book are the same as those for sale at a number of vendors.

Point 2. I believe that if you manufacture a modified top wishbone, you will have problems with clearance for your coil and damper.

Point 3. The latest attachment you have added has wrong dimensions on it,

Hope this helps.

I built mine as per the book before I found out about any castor problems so it only has a little castor, but it still works. You just don't

generate as much self centring force. If you are not a driving critic you probably won't even notice. All it seems to mean to me is that I have

to turn the wheel to straighten up after a corner. I'm not going to start hacking it about to fix what I don't see as a problem anyway.

yours, Pete.

So is there a correct answer to what needs to be done?

Is it best to go with the jig for the bracket placement and then modify top wishbone by 10mm or will that cause problems with coil overís?

Is it best to move upper wishbone brackets back 10mm?

Argghh Just as I thought I was getting somewhere with the chassis!!!!

If the book dimensions set the top balljoint 10mm back from the bottom this surely gives 2.65 Degrees instead of 5.3 How much of an issue is the extra

2.65 Degrees???

Are the drawings wrong in the 2nd addition

Yes m8, the drawings are wrong in the 2nd edition.

If you look at some "manufactured chassis" where they have realised the mistake, you will see the front top brackets hanging off LA and LB

and then a gusset welded into postition to try and achieve some much need strength.

It is nice to see some comments from guys that did not notice the problem and say that it only causes minor handling problems. I suppose the choice is

up to the individual.

I chsoe the modification of the chassis route as i wanted full contact on LA and LB. i have pics if it helps?

Hornet a picture would be good if you have one.

Have you modified the top wishbone as well as the mounts or just moved top wishbone mounts back 10mm and built the wishbone as the book?

[Edited on 25/4/03 by Gremlin]

Hi Gremlin

I have used standard wishbones as per book.

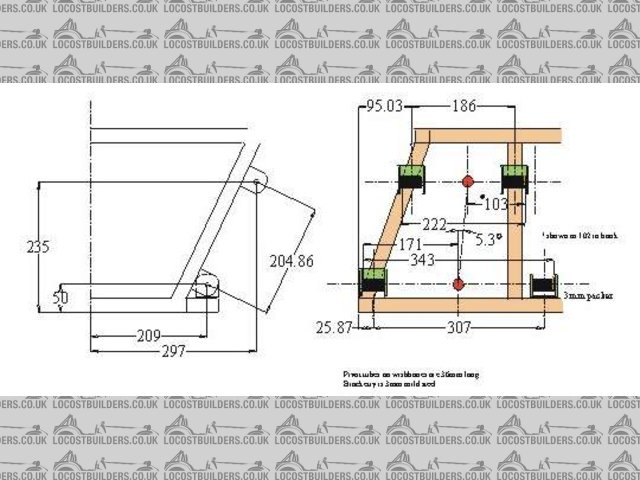

And placed brackets as per the attachment

[Edited on 25/4/03 by Hornet]

And the end results are as below

Looks good.

So just to check all you have done is lent LA and LB back another 25mm so LC is actually 4" behind LD not 3".

I think i might to that then. Although i have only tacked it in place its going to be a pain in the backside having to move S T and R. Oh Well

If i do what you suggest and move LA LB back i take it this jig is wrong.

The jig would only be correct with book chassis and only then put the top wishbone 10mm behind bottom unless i modified the top wishbone?Image

deleted by owner

Yes m8, jig is wrong.

And i will say again.... if you modify the top wishbones.... you will not be able to get spares of the shelve and possibly interfere with the

shocks.

I have a CAD of the dimensions at home if thats any help?

PS i was looking at some pictures and if you look at this picture from Wadders section, you will see the brackets hanging off LA and LB with the

gusset added for strength.

Drawings would be good thanks.

Email that works is mike_coutanche@weymouth.ac.uk

any body able to circle (and explain) the difference between this and the book, Have just looked at the pic at the top of page 64 of the second edition and cant see the difference????????????

You can add an extra tube to make sure the brackets are fully supported, like this:

That's what I've done on mine and the shocks clear it ok.

This one of the parts of my own chassis I am working on at the moment and the more I look at it the more I am convinced the front suspension mounts

are a gigantic bodge carried over from when Westfield converted from Midget to Ford parts.

As I see to do anything about it means a fairly major redesign of the front part of the chassis which has major knock on effects so would in effect

mean starting with clean sheet of paper.

quote:

Originally posted by MikeRJ

You can add an extra tube to make sure the brackets are fully supported, like this:

That's what I've done on mine and the shocks clear it ok.

still cant see the difference ????

I'm working on the front suspension myself at the moment. I decided to have some top wishbones fabricated for me with the additional rearward

offset because

1. I don't like the idea of the brackets hanging so far off the chassis tubes, just doesn't seem right.

2. It doesn't look like the shocks will foul on the 'custom' top wishbone if the top mounts are positioned under the top rail as per

the book.

3. I'd rather have the bother of getting some more 'custom' wishbones fabricated than having a suspension failure.

4. If the top and bottom suspension brackets are positioned carefully the extra rear offset required can be as little as 6-7mm.

[Edited on 17/3/05 by GaryM]

I chose to make new top bones and put camber adjusting sleeve in while I was about it, no issues with spring clearance and the brackets look right. In

the old book the drawing calls for the bushes to be 4" and 4.75" either side of the ball joint centre, which is wrong. The dimensions should

be 3 5/8" and 5 1/8" to achieve the 3/4" offset that was intended.

Wimmera

As I'm working on the "L" front bit of my chassis now, would I be ok using 25mm round for the top and bottom pieces and setting them

4" apart instead of 3"?

I am using standard bones.

Cheers,

Pat...

i built a jig for mine (pics in my archive) based on the drawing in James' archive! I have also braced the wishbone brackets on the fu tubes as

they were hanging off slightly once all jigged and welded into position.

my fu tubes line up with the e tube, but it wasn't the case originally as i bought the chassis tack welded together and have had to redo more

than if i'd started from scratch  . there are some pics in my archive showing the original positions of the fu tubes by the previous owner of

the chassis with the fu tubes hanging off tube e.

. there are some pics in my archive showing the original positions of the fu tubes by the previous owner of

the chassis with the fu tubes hanging off tube e.

Ned.

[Edited on 18/3/05 by ned]

Thinking it over the real problem is the lower wishbone the balljoint should be located 25mm forward, but trying to located it correctly with the

book chassis can't be done.

So what iff a modified lower bone was made to mount the rear pivot directly on FU1/FU2. The lower end of LA/LB would have to be moveed outward.

The top wishbone would be to be "wide track".

Up side, better caster less bump steer with a standard Escort rack, on the

Downside the camber gain is changed (partly offset by increased caster).

redesigned wishbones ahs been done before. I tihnk it wa Mark alanson who did a different top wishbone to set the castor..

Ned.

BS, Must be easier just to make a new top bone, surely, have a look at the drawing on page 82 of the first book and read the note in the corner, they

think they have allowed for the castor, but they made the fatal mistake of not working to the centrelines, hence they only got the drawing half

right.

Wimmera

As I see it one of problems with the book upper bones is if you start modifying them to increase the castor the weld on one rear leg becomes quite

nasty --- because of the acuteness of the angle most MIG nozzles won't get near it.

MK style uper bones are much better in this respect but making a pair of identical bones without building a really good set of jigs first is

difficult.

The other alternative is build something like the ones shown on the pictures on the Lolocost site --- which takes the form of a track control arm

and brake reaction rod rather better versions of this design were used on a lot of older single seater racing cars, but apart from being a step into

the unkown somehow it is tainted by association with Lolocost.

[Edited on 18/3/05 by britishtrident]

quote:

Originally posted by britishtrident

I have been toying with using something similar made from 40x18x1.5, the main reason I haven't tried it so far is that I wasn't sure it would clear the damper and I thought it might look silly.

B/S, dont think the welding is a valid point, I TIGGED mine and that was about 5 years ago, it's done a lot of miles since then. It amazes me

that some of the suppliers have yet to catch up with this error, they must be a switched on bunch.

Wimmera

quote:

Originally posted by Avoneer

As I'm working on the "L" front bit of my chassis now, would I be ok using 25mm round for the top and bottom pieces and setting them 4" apart instead of 3"?

I am using standard bones.

Cheers,

Pat...