Rescued attachment adapter2.jpg

Does anyone have a detailed drawing of the Sierra upright inserts?

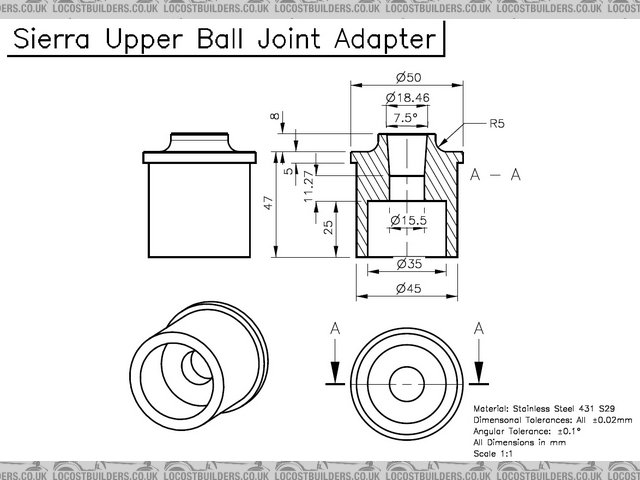

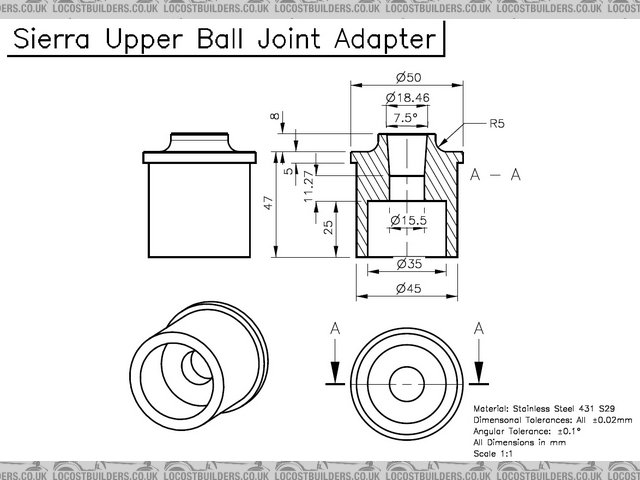

Does this help?

Rescued attachment adapter2.jpg

Hey i recognise that

I was going to say something, but I have heard that something is wrong with my drawing. Nobody will tell me what though! Which doesnt help, if someone

would then I will put it right!

Cheers,

David

That one you have posted has the wrong balljoint taper on, this one has the right angle on. But my comments above still stand true!

Image deleted by owner

[Edited on 2/6/06 by flak monkey]

are you sure its 7.125 degrees and not 7? Just a guess

The angle is an odd one. Its in inches per foot, i cant remember exactly what it is and cant be bothered to work it out at the moment

is this what is meant as reaming the bottom taper out?

i have seen mushroom inserts on GTS. is it the piece you are describing?

not quite robert. With a standard sierra upright, neither top nor bottom are right. The lower taper is wrong, and this is what needs reaming. The top

needs an insert to put a taper at the top.

IIRC there are 2 main tapers one is 1 in 6 (2" per foot) and 1 in 8 (1.5" per foot) which I beleive this is, and if so 7.125 degrees is very

close....my calc says 7.125016349

About the drawing...there is no dimension for the diameter at the top of the part.

HTH

Alan

so, how should i modify my uprights? i really dunno what reaming and taper mean  is it drilling out a bigger hole? or aligning them?

is it drilling out a bigger hole? or aligning them?

a taper is a wedge shaped hole, you would ream it out to a new angle and size. Most people in the uk get manufacturers to do it, as its not simple for

normal people.

quote:

Originally posted by JoelP

... as its not simple for normal people.

oh my lord. so that means i cant use my sierra uprights per se. or simple mods... for the sake of simplicity and quickness... is there another

substitute for the cortina uprights?

wait a tick... the problem with the sierra uprights is that they dont fit the ball joints right? or at least they have a different angle to that which

we want for the geometry of a locost right? so wouldnt simply changing the design of the front suspension to fit these uprights tackle this

problem?

would mini uprights do the job? what about miata/mx5? they are being used right?

I seem to remember hearing that Mk2 Astra ball joins will fit the bottom taper on the sierra upright...

Not sure if its true or not though.

David

Simple solution is modify the wishbone ends to take spherical joints, then drill the sierra upright straight through for the bolt.

It's what you'll find on most racecars.

Cheers,

Syd.

good idea there syd. Either that, or buy an adapter from raceleda (not as expensive as it sounds), this bolts into the lower taper and takes a rose

joint.

For the top, you can just get a pair of mushrooms posted to spain if required.

i cant believe i'm being so thick on this. please bear with me.

the problem with sierra uprights is that they wont fit transit (top) or maxi-ball (bottom) joints right?

yep, thats the one

this seemingly odd affair stems from the fact that original locosts used cortina uprights, which do indeed fit cortina balljoints (odd that one  )

and transit draglinks. However, when people changed to sierra uprights, they kept on using the original joints. No idea why

)

and transit draglinks. However, when people changed to sierra uprights, they kept on using the original joints. No idea why

[Edited on 4/6/06 by JoelP]

so the solution lies in using the proper ball joints.

why oh why dont we use the sierra balljoints? just get them new from the dealer or another source?

indeed, i could use the sierra joints and adapt them to the wishbones?

[Edited on 4/6/06 by robertst]

Possibly for the bottom joint, but the top one should house the macpherson strut. This is the main problem with the top one. The bottom one may be because the joint is an integral part of the bottom arm on a sierra, but I'm not sure on this one.

correct si

worth using the astra ones if they do indeed fit.

thanks joel for ur help. i know i could use the bottom sierra joints and just get adapters for the top and thats it. use the transit ones.

sierra lowers are part of the complete track control arm, you would need to either cut it off or use a similar one.

just been reading this thread,,interested about the astra ball joints...i think i will pop over to Halfrauds tomorrow at Dinner when im at work and

see if they will let me measure one..if they have any that is.

these are on ebay.

The astra joint might be to narrow, small end is 13.5 and the sierra has 14 (according to SIDEM)

went to Halfrauds,they dont keep them instock.

I'm not sure the Astra ball joints will be overly suitable as they are designed for use with a McPherson strut, i.e. they only have to support lateral loads rather than any weight.

Thats a good point.

does anyone know what DAX use on their rush?.

I've got some Astra ball joints which i'm planning to use on Sierra uprights. When pressed in by hand there is a small amount of play at the thick end of the taper. I'm not sure whether there will still be movement when it's tightened. I'll try it as soon as i get hold of a nut with a suitable thread. Looks fairly promising though.

Hi, sorry to drag up an old thread here but I was looking for some help with making some of these mushroom inserts.

A friend asked me to make him a couple on a CNC lathe at work and seeing as it’s CNC there is no need to ream the tapered hole as I can bore it out

strait to the correct angle.

He gave me a copy of a drawing which is the same as the second one on this thread, but nether that drawing or the other one on here actually work out

at 7.125 degrees. The first one works out at 9.036 and the second one works out at 8.666, both are quite a bit off...

I was wandering if anyone else had come across this? Should I make it to the drawing and trust they will work, or change the dimensions to get the

7.125 degrees?

Or perhaps does someone have another drawing?

Thanks in advance

Jonathan

Hi Jonathan

No need to appologise for dragging up an old thread - on the contrary, it shows you've taken the time and effort to search the forum.

As far as the taper goes - if you have CNC facilities available, why not get one of the tapers your pal intends to use and measure that?

Regards Mick

I would but the ones he has are far too chewed and corroded to measure accurately, even if they were in good condition the only true way to get close

to 0.001 of a degrees is with a good shadowgraph or CMM, nether or which I have access to at work.

I could probably measure them close enough for what they are doing. But I’m an engineer, I’m not a big fan of “close enough” if I can I generally aim

for “right” and if it ends up close enough then so be it.

He said he would get some new ones but as of yet has not got around to it so I am left waiting.

Jonathan