What do you guys think ?

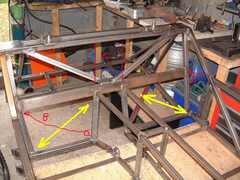

Showing a mate a few photos of progress on the new chassis and he felt I need more bracing. I have beefed up O3 to 50x25x2mm and its a live axle car

so no diff hanging from it ect

What do you guys think ?

Can do if you like.

Not really necessary as that part of the car isnt that structural... The axle loads go through the tubes where the trailing arms mount. In a live axle

car theres pretty much no load on the bulkhead.

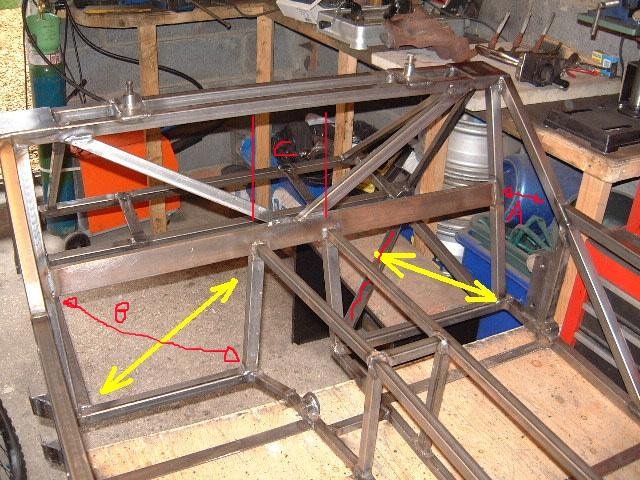

In my pic below I think A will add more strength to the trailing arm bracket tubes, B will add more strength to the rear of the chassis, along with a

fully braced rollbar and I put the tubes in at C but I hadn't doubled up the tubes between the rollbar base plates like you have so probably

unecessary in your case but certainly a belts and braces approach. I was concerned about the single top rail twisting under the weight of two people

as that rail takes most of the forces in a heavy braking/accident scenario.

Ned.

Rescued attachment chassis.jpg

i did but then my diffs hanging off it

Yes -- "union jack" style

The 50x25 was overkill IMHO. The diagonals you propose are useful as they contribute significantly to the torsional stiffness of the chassis

Could you put a steel bulkhead in? It's what I'll probably end up doing. But even then I have another box structure hanging on the back of the tunnel to hold my diff up so no real need for extra bracing.

i would add a 19mm round bar, in 20g. Next to no weight but pretty effective as it's in tension and compression if the bulkhead was to ever try folding up. But if you intend to panel it, which i suppose you have to, then either welded steel or bonded and riveted ally will be more than adequate.

Nice neat looking work.

I know that adds nothing to the thread, but it needed saying

Bones V. Soon

quote:

Originally posted by big_wasa

Showing a mate a few photos of progress on the new chassis and he felt I need more bracing. I have beefed up O3 to 50x25x2mm and its a live axle car so no diff hanging from it ect

What do you guys think ?

quote:

Originally posted by zilspeed

Nice neat looking work.

I know that adds nothing to the thread, but it needed saying

Bones V. Soon

quote:

Originally posted by flak monkey

In a live axle car theres pretty much no load on the bulkhead.

Yup, but those loads are vertical only. The two angled rear tubes, and the side tubes of the rear bulkhead will take these loads as they are purely in

tension.

Of course adding in 2 tubes will increase the stiffness of the chassis, as nothing beats a properly triangulated stucture. But the tubes are not 100%

necessary, especially with that huge tube running across the back anyway. My original answer was on a neccessity basis rather than anythign else.

Makes little difference. Depends if you are bothered about another kilo on the weight...

David

Load might be vertical, but when it's only on one side, i.e. any one wheel bump or corner, it will act to lozenge the rear bulkhead, and the

whole chassis. A chassis without a torsionally stiff rear bulkead will flex horribly under hard cornering.

Of course you could take the american approach - "if we put enough big horizontal bars in we dont need triangulation!"  . I never

said that chassis needs those bars but any triangulation is an elegant way of increasing the efficiency of the structure. Loosing that unnecessary

2"x1" bar and adding the diagonals instead would have resulted in a chassis the same weight and much more stiff.

. I never

said that chassis needs those bars but any triangulation is an elegant way of increasing the efficiency of the structure. Loosing that unnecessary

2"x1" bar and adding the diagonals instead would have resulted in a chassis the same weight and much more stiff.

Liam

[Edited on 7/5/06 by Liam]