RV8 Engine mounts?

bigend - 23/3/03 at 08:38 AM

hi, i know there are a few RV8 builders on here, and i'm wondering how have you managed to make a decent bracket to bolt the engine mounts to?

i'm really stuck for an idea, so any help would be appreciated,

bigend

craig1410 - 23/3/03 at 10:40 AM

Hi bigend,

I've not quite got to that stage yet (soon though). Can you explain what the problem you are facing is exactly and perhaps we can jointly solve

the problem? I am assuming that you have the engine bracket and rubber mounting with the two holes which would normally bolt to the crossmember?

Can't you just fabricate a plate from good thick steel (perhaps two 3mm plates which bolt on either side of the engine mounting holes and then

welded to the chassis in the appropriate place?

Sorry I can't fully appreciate the problem at present but if you can describe the issue more clearly then I'm sure we can make some

suggestions.

Cheers,

Craig.

ps. Simon might be able to help more directly since he's been there and done that...Simon?

Simon - 27/3/03 at 09:42 AM

Bigend/Craig,

Sorry - just spotted thread!!

I used the "engine to mount" brackets that came with the engine (Range Rover I think)

One of them was quite a bit wider than t'other, so that was modified so they were the same width.

I then purchased two (one for each side) rubber engine mountings (from a Land Rover shop) to go into above.

Then the fun bit, engine rubber to chassis mountings!!

For these, I welded some 6mm plate to the chassis rails, then took some 1.5" dia (16swg) round tube to make the "upright" part (these

are angled toward each other at the top).

The tops are slashed so a nut can be put onto rubber. On top of that is a bit a 4mm plate for the rubber to rest on.

Have a look at:

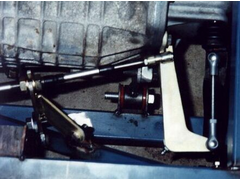

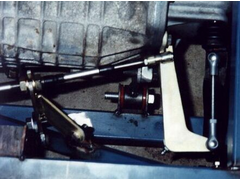

http://forum.locostbuilders.co.uk/xmb/photos/cgi-bin/showpic.pl?100000471.jpg

You can see (albeit not very clearly), the near side mounting.

I'll put up a better piccy tonight if I get a chance or at the w/end if not. I'll do a sketch later and put that up today.

ATB

Simon

bigend - 27/3/03 at 04:52 PM

hi craig/simon,

thanks for the replies, it seems as though your rubber mounts are completely different to mine, and craigs by what i can make out, doh, i thought they

might have been similiar, what is your engine from craig, a P6? it looks as though we're on our own then,

your design of mount was just the sort of thing i was looking to do, very efficient, though i bet it's fun trying to get that nut on the back

i just might have to do an adaption of it, hummmm, think i'll go and stare at it for another few hours,

Simon - 27/3/03 at 05:03 PM

bigend,

My engine is from a P6, which was fitted to a Range Rover, hence the RR front cover.

As for doing up the "rubber's nuts, it's a case of assemble complete engine mounting including the rubber to engine mounting, then

lower the engine in.

Seems to work ok.

ATB

Simon

Rorty - 28/3/03 at 01:03 AM

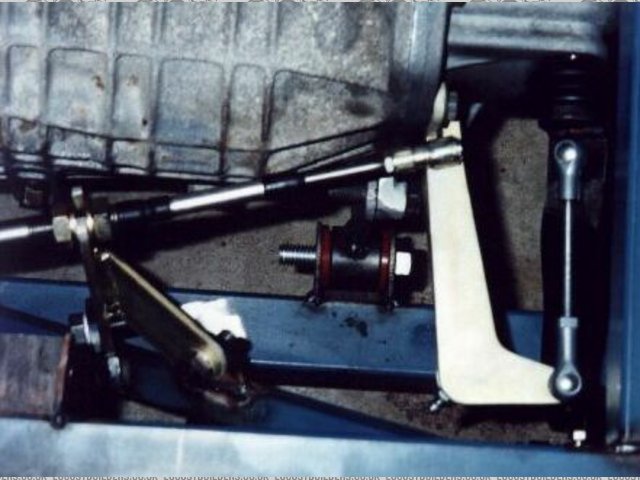

Any car engine that I've ever custom installed, has been done the exact same way.

I start off by cutting and drilling a bit of 8mm flat bar, then weld a "suspension" bracket to the plate, and bolt it to the engine.

Next, I assemble two PU bushes, a crush tube, and an outer bush tube, place it in the bracket on the engine, and pass a bolt through the whole

thing.

Make sure the engine is sitting solidly, and precisely where you want it to be. Next, you need to cut/grind/fit a length of tube/bar with a fishmouth

on the bush end, to run from the bush to the chassis.

Tack weld it in place, being careful not to get too much heat into the bush, melting the PU. Tack on any other bracing tubes or brackets as necessary,

then repeat the whole process on the other side of the engine.

When it's all cooled down, withdraw the bolts from the "suspension" bushes, and lift the engine out of the way. Then you can get up

close and personal with the mounts to fully weld them.

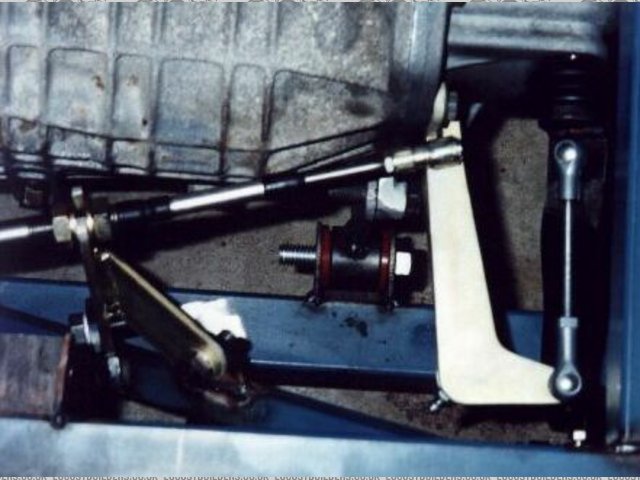

I don't have a pic of this sort of engine mount, but I've attached a pic of a transaxle mounted in a similar fashion.

Rescued attachment Ren_gear_change.jpg

craig1410 - 29/3/03 at 11:38 PM

Rorty,

I quite like your engine mounting idea (if I've understood it correctly), my only worry is are a pair of "suspension size" poly bushes

up to the job of supporting an engine the size and power of an RV8? I dare say I could use two if I was worried about it.

Bigend/Simon, my engine doesn't have any mountings on it at present because it is only a block, sump and heads with no internals or ancillaries

which I'm using to gauge the basic size and shape. I hope to get my actual engine in a week or so and I hope it will have some mountings on it.

The engine I'm getting is from a P6 but it's been in a kit car so may have custom mounts already. I'll let you know what I come up with

once I get to look the problem over properly but Rorty and Simon both seem to have good methods.

I especially like Rorty's idea (sorry Simon) because it must be much easier to detach the engine from the mounts (1 bolt each side).

Cheers,

Craig.

Simon - 31/3/03 at 08:57 AM

Craig,

I quite like Rorty's suggestion too:-(

ATB

Simon

Rorty - 1/4/03 at 03:02 AM

craig1410:

quote:

my only worry is are a pair of "suspension size" poly bushes up to the job of supporting an engine the size and power of an RV8?

If you think about a "conventional" engine mount, they're often just Metalastic blobs with a single 3/8" to 1/2" thread

sticking out each side.

My method uses a single Grade 8 1/2" bolt through the whole thing.

I've used them this method of mounting engines in things like a 4.7 litre Chevy V8 in a short wheelbase off-road racer, and they work fine.

I have mounted quite a few RV8s in this manner in some of my mid-engined Beetles, including a 5.1 litre monster.

Cruising around the roads with an ordinary little RV8 shouldn't be a problem.

craig1410 - 1/4/03 at 12:01 PM

Rorty,

I think I've upset you now...

Seriously though, I was just curious to know if a "little" suspension bush could cope with the constant weight of the "little"  RV8 engine. The static weight is about 300 lbs but the dynamic weight when going over bumps etc must be 2 or 3 times this figure (at a rough guess).

As you say, a "conventional" metalastic mounting is a blob of rubber between two metal plates with a bolt sticking out of each end. The only

difference I can see though is that this rubber blob is predominantly under compression with a bit of lateral and longitudinal forces from time to

time.

RV8 engine. The static weight is about 300 lbs but the dynamic weight when going over bumps etc must be 2 or 3 times this figure (at a rough guess).

As you say, a "conventional" metalastic mounting is a blob of rubber between two metal plates with a bolt sticking out of each end. The only

difference I can see though is that this rubber blob is predominantly under compression with a bit of lateral and longitudinal forces from time to

time.

in any event, I'm not going to argue the point because the examples of where you have used it successfully speak for themselves. I very much

believe in experience before theory in cases like this so I will certainly take a look at implementing your idea on my car.

You don't have it patented or anything do you...

Cheers,

Craig.

Rorty - 2/4/03 at 02:03 AM

craig1410:

quote:

I think I've upset you now

Not at all.

quote:

You don't have it patented or anything do you

No, go for your life!

If you have any doubts about the strength of a PU suspension bush in such a situation, you could try a larger version. Something like 4WD trailing arm

bushes or leaf spring eye bushes. You'll probably have to use a larger diameter bolt with those bushes, but if you don't mind the extra

weight.....

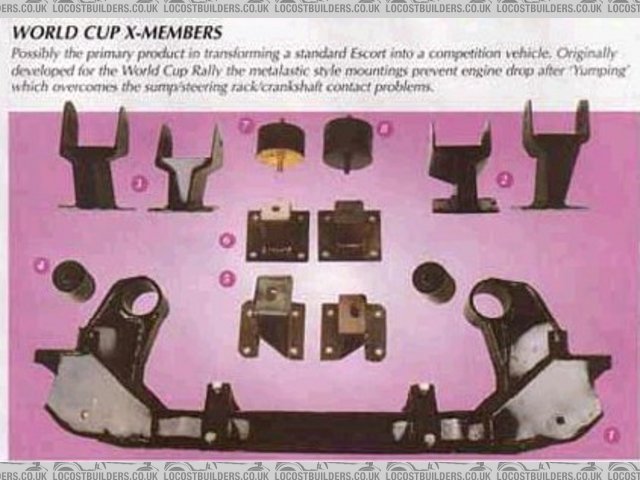

timf - 2/4/03 at 09:32 AM

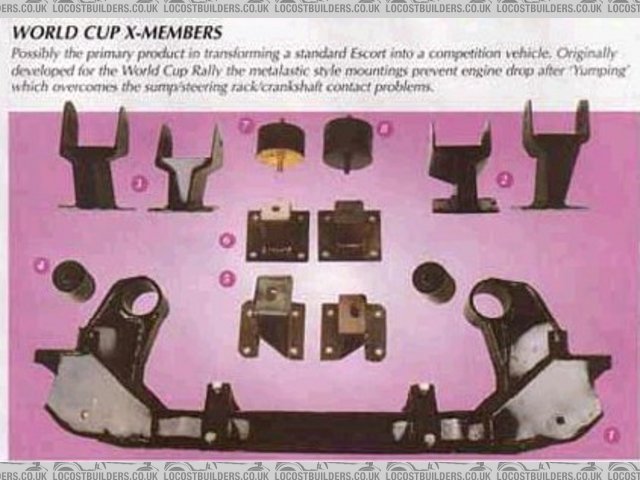

In the old mk2 rally cars the ran a world cup crossmenber which was mainly a captive rear leaf spring bush to which the engine was attached. see

attached image,

it prevented the engine mounts from breaking and dropping when going over jumps.

craig1410 - 2/4/03 at 11:33 AM

quote:

Originally posted by timf

see attached image,

Nope!

I get the picture though (no pun intended) and it sounds like a sturdy solution. I'll maybe have a hunt round my local scrapyard this weekend to

get some ideas.

Cheers guys,

Craig.

timf - 2/4/03 at 02:09 PM

opps no picy

Rescued attachment wccm.jpg

Rorty - 3/4/03 at 01:48 AM

That looks exactly like what I was recommending, only bigger and more crude.