Rescued attachment triangulation.jpg

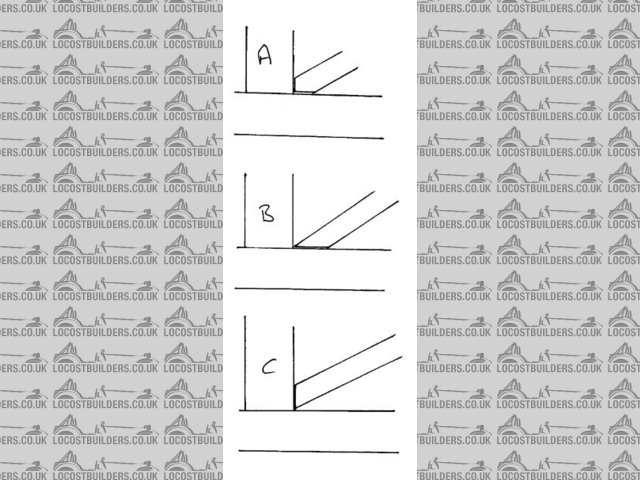

Hopefully will make a start on the triangulation this weekend and was contemplating the best way to cut the ends of the tubes. The options seem to be

as below, is any one of them preferable? My own thought is that A would be best, but most complex. If it makes any difference to the answer, my choice

is to double triangulate (making a cross) using 13mm square rather than the usual single diagonal round section.

Rescued attachment triangulation.jpg

The A option is the best.

Dieguez

A is the best, and makes more sense ...

Why make a cross though? Your not really going to need it, and will make your chassis heavier. Once you have a tube welded properly and securely

inside any of the square /rectangular shapes on your space frame, it will lock it up and strengthen it anyway.

Seems like a waste to me

'A' is best, 'C' passes MSA roll bar design specs, 'B' does not !.

Regards Mark

quote:

Originally posted by Johnathan

A is the best, and makes more sense ...

Why make a cross though? Your not really going to need it, and will make your chassis heavier. Once you have a tube welded properly and securely inside any of the square /rectangular shapes on your space frame, it will lock it up and strengthen it anyway.

Seems like a waste to me

ditto 'A', with load spreading fillets if you really want to get carried away!

hi

the round bar is used for the triangulation because its cross section makes it more resistant to side impact, on the chassis this is the triangulation

down each side, box section will deform much easier on side impact,

HTH

Mike

Is it weaker even if I fully weld the point at which the two tubes cross? I would have thought that would create a kind of net effect which can be pretty strong.

I'm not an expert but I was told by someone who should be that the tubes whether round or square are much stronger in tension than compression.

It is just as good to go in one direction only so long as you put the tube so that the load causes it to be in tension.

Bruce

On that principal, if you have a rectangle with a cross in it, for a load applied to any corner one of the cross tubes would be in tension and the other in compression so would you have the best of both worlds?

without doubt A is the stongest.

What profile of tubing are you welding to what? i..e. round tube to round tube or square section tube?

If you are welding round tubes, there is a program that by entering diameters, angles, etc: prints on paper the fishmouth profile you need. You cut

the paper and stick it on your tube then cut the notch in the metal. Now someone is going to ask where to find this program........

quote:

Originally posted by 02GF74

...

If you are welding round tubes, there is a program that by entering diameters, angles, etc: prints on paper the fishmouth profile you need. You cut the paper and stick it on your tube then cut the notch in the metal. Now someone is going to ask where to find this program........

So far it is all square section tubing. The round comes later for a few other bits.

quote:

Originally posted by 02GF74

without doubt A is the stongest.

What profile of tubing are you welding to what? i..e. round tube to round tube or square section tube?

If you are welding round tubes, there is a program that by entering diameters, angles, etc: prints on paper the fishmouth profile you need. You cut the paper and stick it on your tube then cut the notch in the metal. Now someone is going to ask where to find this program........

Triaxial stress systems were yet to be invented when I did my apprentiship!

The theory taught in the 1980's was that a single stress point was used to line up the tubes. The bisected lines are on the centreline of the

horizontal tube and the centreline of the vertical tube, and the triangulation would be added so it 'points' to the cross in the 2 lines, so

A is the nearest to the ideal. It also adds to the bracing of the 2 other tubes.

[Edited on 15/12/05 by Mark Allanson]

quote:

Originally posted by mike4444244

hi

the round bar is used for the triangulation because its cross section makes it more resistant to side impact, on the chassis this is the triangulation down each side, box section will deform much easier on side impact,

HTH

Mike

quote:

Originally posted by clbarclay

Square section RHS is stronger in bending (higher second moment of area) compared to round tube of the same mass per meter, not diameter.

quote:

Originally posted by clbarclay

snip

????

Unless i've miss under stood the reasons for what your saying, they teach the opposite when calculating bending stresses at uni.

Square section RHS is stronger in bending (higher second moment of area) compared to round tube of the same mass per meter, not diameter.

In bending square sections have a greater max bening stress, but round sections can withstand higher (margianly) max torque.

quote:

Originally posted by britishtrident

You misunderstood for a framed structure round tube is more efficient per unit mass.

quote:

Originally posted by clbarclay

quote:

Originally posted by britishtrident

You misunderstood for a framed structure round tube is more efficient per unit mass.

Is that to do with energy absorbtion then, rather than the bending moments?

Not forgetting that square section is only strong in two planes, apply a force at 45 degrees to a flat section and it will collapse with much less force.

If using option A is it better to weld the two tubes in the corner then grind the weld and then fit the triangulation, or should the triangulation be

fitted without welding the corner that it will be covering?

This isn't a problem with option B or C because non of the joints are covered by the triangulation.

So weld and grind, or dont weld just fit the triangulation over the joint?

Cheers.

weld and dont grind. You might have to take a little top and bottom, but in the middle it will fit snugly inside the tube. If a resulting angle ends up too tight to weld inside, take a wedge of tube and weld it over it.

quote:

Originally posted by Mark Allanson

Triaxial stress systems were yet to be invented when I did my apprentiship!

The theory taught in the 1980's was that a single stress point was used to line up the tubes. The bisected lines are on the centreline of the horizontal tube and the centreline of the vertical tube, and the triangulation would be added so it 'points' to the cross in the 2 lines, so A is the nearest to the ideal. It also adds to the bracing of the 2 other tubes.

[Edited on 15/12/05 by Mark Allanson]

ive been spending hours recently in the garage grinding 50x50x3 square tubes to fit in style A, and coincidentally, it is the centrelines that line

up! I'll chuck up a picture soon, as it will make a nice example being in large tube. Plus you can all ridicule my welding

I'd say A. The Tao is in the Symmetry.

Considering I'm doing Further Mathematics A-Level you woulda thought I'd give a more logical answer, eh?

quote:

Originally posted by MikeRJ

For the case where the round tubes diameter = distance accross flats of the square section, the latter will be the heaviest and strongest.