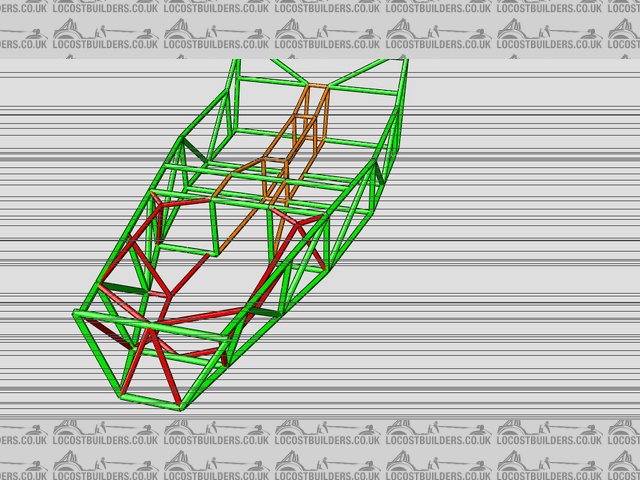

Rescued attachment izometric.jpg

What do you think about this chassis ?

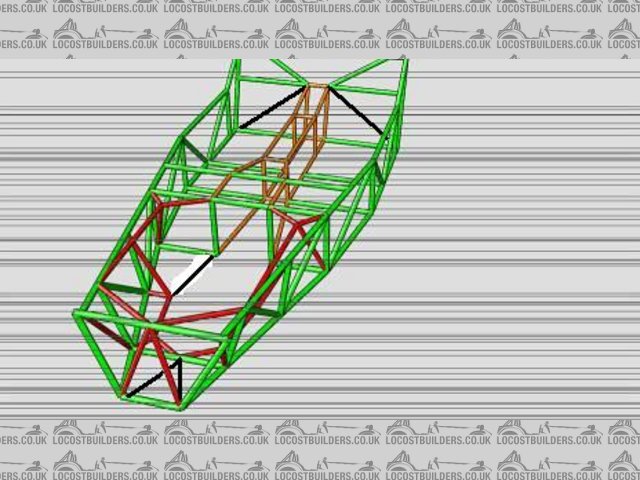

Rescued attachment izometric.jpg

What's new about it?

Look like Cymtrics / Aussie mods to a book chassis.

Pat...

the red bits

Looks good

still room for improvement. You interested in constructive criticism?

heres some anyway. New lines in black

Rescued attachment locostchassis.jpg

Mijovil, are those Penguin lines, or what's happened to your drawing?

do any of the locost manufacturers manke Cymtrics style chassis ?

It looks familiar, any proof it works.

Rescued attachment izometric.jpg

the diagonals which go to fu1/2 will make it difficult for anybody with inboard supension .

I was talking about this sort of thing with NS DEV last night.

What are you trying to achieve? The stiffest locost for the race track or for the road?

The engine bay is a weak point on the locost so in a crash it will crumple and hopefully keep you in one piece. Make it too strong and ..... well you

might find the crumple zone is your body.

If you claim you're not going to crash then you probably aren't going to be driving quickly so do you need the 'best' chassis?

(and are you sure of everyone else around you isn't going to hit you?)

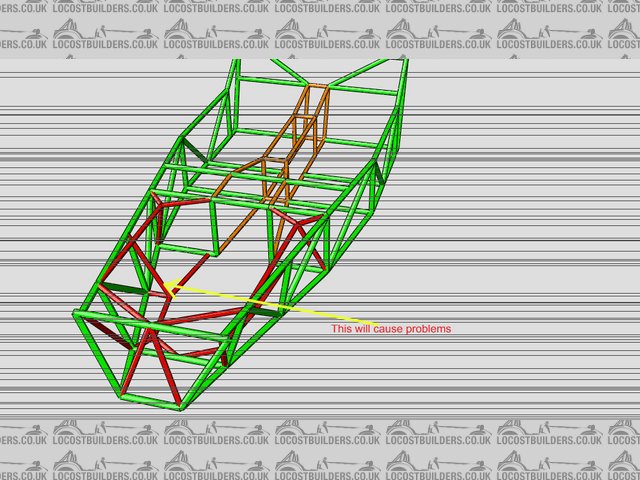

Also Peteff - i agree about that line you highlighted.

quote:

What are you trying to achieve? The stiffest locost for the race track or for the road

ok, i'd be interested in your figures (although doubt i could understand them).

this is the sort of thing i go hot and cold on.

First response is .... oooh, must improve my chassis then. Then i think, hold on, lots of people love driving these cars and think they handle really

well....... at which point i'm back to the - do you need it?

One addition i'd try and do is complete the tube at the bottom of the trans tunel enterence.

I'm also assuming you mean front wheel.....

well why use 'Y' braces around the engine? Use the standard single brace - thats stronger. Make the sides of the engine into a sheet - lots

of rivets to two sheets of ali either side of the tubes - should help and still give hte engine bay a chance to crumple.

Mike,

I'll redo the calculations to see if I was right later on tonight - hope I don't end up with a red face.

I tend to agree that I'd prefer strengthening around the driver / passenger compartment

A single Y brace is slightly less strong and less stiff than a single diagonal brace. The order goes like this..

single Y brace

single diagonal (book chassis R tube)

double Y brace

double diagonal (as on the Caterham chassis)

The reason I suggest a double Y brace is that it gives a very good improvement if strength and stiffness over the book design while at the same time

giving the best possible engine bay size. Many builders report that the single R tube snags on engine ancilliaries, the Y brace is less likely to do

this.

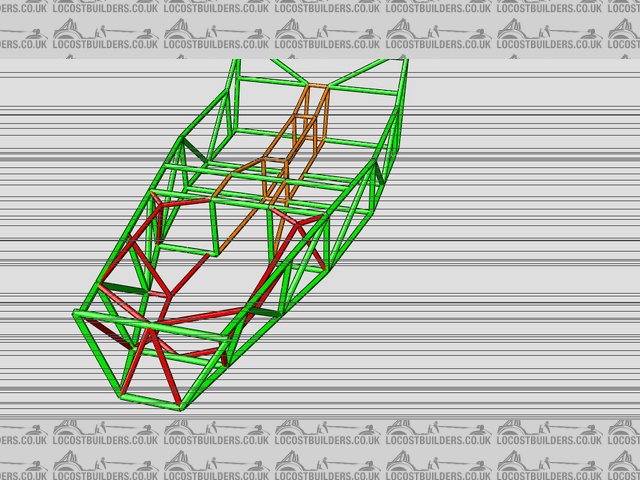

If you are using a normal size engine, less than 1.6/1.8 then I'd suggest my double Y brace mods. For a bigger engine the front of the chassis is

getting marginal and some builders report that tubes TR1/2 flex.

I suggest something like this design which is in the "bigger engines" section of kitcaranalysisv2.doc for 2.0 and over...

edited to change the first sentence which didn't make sense before! Damn kids distracting me!

[Edited on 6/10/05 by cymtriks]

Rescued attachment framelc_bigeng.JPG

my only concern wit this approch is the red triangle in the middle. You're introducing loads into the middle of a chassis rail - i'm not an expert and i've learnt most of my fag packet space frame theory off this site, but i thought that was a bad idea!

quote:

Originally posted by MikeR

my only concern wit this approch is the red triangle in the middle. You're introducing loads into the middle of a chassis rail - i'm not an expert and i've learnt most of my fag packet space frame theory off this site, but i thought that was a bad idea!

quote:

A single Y brace is slightly less strong and less stiff than a single Y brace