Rescued attachment sb bracket.JPG

I need some advice on the bottom outer fixing point.

The original idea is to use the lower trailing arm bolt which goes through the fully welded triangular plate, but this needs longer bolts, but the

next bolt length up means the threaded section is not long enough and the shouldered bushes need boring out to fit the M12 bolts.

So I am considering drilling a new holes to use the correct size 11/16" UNF bolts in the position shown in the attached pictures, the outer

trailing arm bracket is fully welded to the 1" sq section tube and to the panelled section.

Comments on the idea would be much appreciated.

Eric

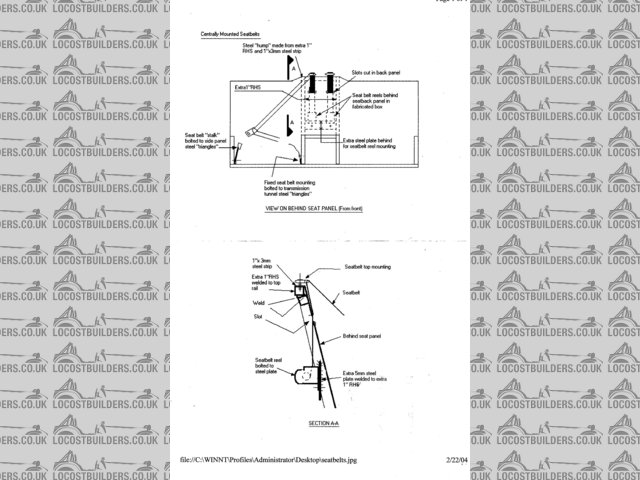

mine has a welded threaded tube sitting on the joint by the rear suspension mounts - hope the pic helps - if it attaches!

Rescued attachment sb bracket.JPG

It will be pretty solid although it has the disadvantage of attaching the belt to the suspension but this is diificult to avoid Mark Allanson did

some nicely engineered seat belt mounts with Mark's usual first class finish.

[Edited on 16/3/05 by britishtrident]

I seem to recall that it was an SVA fail to mount it under a suspension bolt.

If u take a hit to the suspention and it rips this bit off......mmmmm there goes your mounting.

For a couple of hours and ten pence worth of plate ....

where did you get the threaded tube from as i need 8 x 1" for mine.

Marc Norden supplies threaded tube http://www.mnrltd.co.uk/Brackets.html

[Edited on 16/3/05 by britishtrident]

Rescued attachment seat-belt-boss-weld-on.jpg

steel stock, a drill and tap

Heypresto threaded tube, just like the top front wishbones.

Then again you might have bought ready made wishbones and don't fancy the work just for a few seatbelt mounts.

yep i bought my wishbones a few years ago - in fact i think i was one of tritons first customers waaay before they teamed up with GTS.

yep i bought my wishbones a few years ago - in fact i think i was one of tritons first customers waaay before they teamed up with GTS.

although having checked the web site MNR's are 3.50 ...... heck i wasn't expecting to pay that much!!!! any one know of cheeper?

You could weld a thick triangular plate into the corner, drill a hole in the plate use a nut+bolt to mount the seat belt.

This should work for the lower belt mounts.

I'm after some threaded tube for the top seatbelt mounts. Darren has them listed onthe gts site at 1.95, i have emailed him and am awaiting a

reply. Unless there is a better option this is probably what i'll go for as i need the its in about a week as i plan on finishing the chassis

over easter and will need all the bits to finish it off before powder coating..

Ned.

where abouts, i hunted and couldn't find them. £1.95 is what i'd expect to pay ..... so it looks like darren gets my money

MikeR......Am i right in thinking you haven't finished it yet!!!.....you collected those in 2001 not long after i set up in that dodgy unit in

Northampton.

Mark

You will need 8 of those 20mm dia doodahs with 7/16 unf threads

in the chassis section, look hard as its a small 1 line bit with a broken pdf link and no picture, think it's just under the pedal boxes...

I only need 4 for the tops as i've done the bottom mounts out of triangles of 3mm plate..

Ned.

note the type of car i'm building - slowcost!

Organising the midlands meeting takes a lot of time + there are girls to chase and ..... errm .... well no i've not finished

but i will one day, hopefully going to redo the side triangulation of the engine bay to tie it up with the nearside diagonal i'll add which will

then allow me to fit the caterham exhaust i've got.......

then its seat belt mounts,weld in the rad mounts i've had made for a year (although i'll probably remake them), make my fuel tank, get NS

DEV to sort out my roll bar, paint it, wire it up, redo lots and ..... ooh, make my brakes and ... and ... etc etc

quote:

Originally posted by ned

in the chassis section, look hard as its a small 1 line bit with a broken pdf link and no picture, think it's just under the pedal boxes...

Ned.

oh well...

oh well...

oops! sorry, at least they are slighlty cheaper than mnr's..

maybe darren can do us a bulk discount lol

unless anyone else out htere would be willing to supply some suitable threaded tube for a cheaper but reasonable remuneration?

Ned.

3mm plate with 7/16 unf full nuts (unplated)welded on then but won't look as neat unless you get fancy with the brackets especially for the ones on show.

i was gonna use threaded tube to try and get a bit of extra height to make sure the required seat base to harness height is correct for sva.

the plate and nut idea is a good one (though i only have nylocks which will melt during welding!) as it could be hidden by a tonneau style boot cover,

will have to see.

Thanks Mark..

Make a channel section with a 7/16unf clearance hole....shape it so it looks like it was thought about then weld that on.

You shouldn't have to raise the mounts if you have low seats....besides taking the mounts too high has all sorts of other problems.

I remember a guy years ago raised his mounts. The birmingham test centre made him brace the mount as it was adding a bending motion onto the top rail.

quote:

Originally posted by clbarclay

steel stock, a drill and tap

Heypresto threaded tube, just like the top front wishbones.

Then again you might have bought ready made wishbones and don't fancy the work just for a few seatbelt mounts.

quote:

Originally posted by MikeR

I remember a guy years ago raised his mounts. The birmingham test centre made him brace the mount as it was adding a bending motion onto the top rail.

whats the westfield camel hump - have you got any pictures?

quote:

Originally posted by MikeR

whats the westfield camel hump - have you got any pictures?

so the hump is simply a bit of steel welded onto the top bar and profiled to give extra height for the seatbelt mount..?!

Ned.

Yes apart from height it adds bending & torsional stiffness to "O"

not sure about bending. the seat beld is now anchored further away from the verticals that hold O in place, thus acting as a lever to bend O

quote:

Originally posted by MikeR

not sure about bending. the seat beld is now anchored further away from the verticals that hold O in place, thus acting as a lever to bend O

What about the alternative used by luego for example, which is to have a lower tube in the roll bar which has the seat belt bolted to it.

Does this design have any particular draw backs if you need higher seat belt mountings?

Just been over to a friends workshop this evening and he so happens to have a lathe, drills and 7/16" unf tap.

Only problem now is that the rod we started turning down and tapping turned out (no pun intended!) to have a seam through the middle of it, so we came

to the conclusion that (the old shuttering pin we were using) must be rolled somehow in construction and hence wouldn't be up to the job once

turned down to the right size

Problem i have now is sourcing a foot or so of 16mm + rod. it can be larger diameter as i have the ability to turn it down, but i can't get

anywhere as i work in london and am away this weekend.

can anyone help? i can't see the point in paying for the threaded tube when i can make it myself but you can't buy a 12" piece from a

stockist as there will be a minimum length and delivery etc so it becomes unfeasable.

suggestions?

Ned.

Ned, i'm formulating a cunning plan ...... send me a U2U telling me how quickly you want these mounts - I might be able to get you the steel but

it will cost you 8 1" mounts and postage back

(this is assuming the steel and postage to you costs less than 8 mounts from Darren)

[Edited on 17/3/05 by MikeR]

Why not buy 16mm bolts and fabricate the tubes from them?

Mick

Ned.... Quote- the plate and nut idea is a good one (though i only have nylocks which will melt during welding!) as it could be hidden by a tonneau

style boot cover, will have to see.

I have used plate welded with bolt and nyloc nut. I am of the belief this will pass. There is no need to weld the nut on?

J

Welding the nut on just makes things a lot easier, you put the seat belt anchor through the plate and don't have to worry about getting a spanner

in behind.

Also by making the threaded part as large as possible (i think) youre making it safer as there is more steel to counteract the bending force.

Although if a single bolt on a suspension mount is acceptable on a production car this is probably a non issue.

Mix,

We thought about using bolts, but has most are coated/hardened we thought it might cause problems when cutting on the lather and damaging his bits.

I'm planning on making the threaded tube and welding it through the top chassis rail, not behind it as this should be strongest. If necessary

I'll make a top hat/sleeve to raise the belt if necessary for Sva.

MikeR,

That sounds like a good arrangement. I'd like to get the mounts made by the end of next week as I'm hoping to complete my chassis for

powdercoating over the easter weekend. Check out the postage cost and let me know (I'll need a longer length to do yours as well obviously, prob

nearer 2' so bear this in mind.

I was working on 7/16 unf tap and turning the od down to approx 14mm on the tube, to make drilling through the chassis rail as easy as possible. 13mm

won't leave enough meat round the thread and will probably lead to distortion when welding.

Ned.

[Edited on 18/3/05 by ned]

BZP 8.8 bolts will turn fine and won't dasmage the lathe or tooling

Mick

Thanks for the info mix, would be good if I had any bolts big enough, but don't think anything i have has 14mm+ shank. will wait and see if miker

and i can sort something out.

Miker,

thinking about postage costs, it must be cheaper to send me some steel bar/rod than pay darren £23 + postage for his tubes.

royal mail standard parcels is about £10 for upto 10kg iirc, that would cover it surely..

Ned.

Ned.

[Edited on 18/3/05 by ned]

Ned, need to cost postage but i can get two 15mm mild steel bars 30cm long from metal supermarket. one for you, one for me for £3. I'm guessing

worst case postage is £7.20..........

so return postage back to me shouldn't be more than 7.20.

I think its worth it, so are you interested?

[Edited on 18/3/05 by MikeR]

Mike,

agreed, will u2u my address..

Ned.

ps if you could get me an extra 30cm bar and i'll reimburse you the difference + any extra postage cost that'd be well handy.

[Edited on 18/3/05 by ned]

u've got u2u Ned and don't worry about the extra bar, it was something like 1.50 ex vat.

u2u backatcha..

Just to bring this one back up, here's a pic of how I sorted my top mount out inthe end and gained a bit of extra height that i needed...

top harness mount

Ned.

Thanks for the post ned, youve just answered something thats been bothering me for a while. I can run a hoziontal bar along my roll bar next to the

chassis top rail with the diagonal feeding to the top of that and it will clear where i'll be putting the seat belt mounts.

I was going to weld into the top tube, but due to the diagonal on the underside of the outer mounting points I wouldn't have been able to weld

around the bottom of the inserted threaded tube. The addition of another tube made most sense as it raised the height of the mount, hence killing two

birds etc.

I may also add another vertical member below the top chassis rail inline with the inner mounts to reduce the stress on the top member from the

twisting motion which is now exagerated as the harness mounts are higher hence giving more leverage to twist the top chassis rail under braking/weight

on top harness mounts (hope you're still with me..)

Ned.